Dr.-Ing. | Computational Mechanics | AI in Engineering Science | PINNs, FEM, Data Science & Computer Vision 🚀

Passionate about developing and applying advanced computational methods and AI to solve complex engineering and scientific challenges.

🛠️ My Tech Stack & Expertise

Languages & Scripting:

|

Machine Learning & AI:

|

Computational Science & Simulation:

|

Tools & Platforms:

|

🚀 Highlighted Projects Details for each project can be expanded by clicking on them.

1. Hybrid ML-FEM Viscoelastic-Viscoplastic Damage Model (Published in CMAE)

- Objective: Implemented a sophisticated finite element model combining traditional constitutive laws with LSTM neural networks to simulate complex material behavior in epoxy nanocomposites under cyclic loading, considering moisture and nanoparticle effects.

- Tech Stack: C++, deal.II (FEM Library), Python (for ML aspects), MPI, CMake.

- Key Contributions: Developed a hybrid ML-FEM framework for large deformation solid mechanics, integrated LSTM for computational acceleration, modeled multi-network viscoelastic-viscoplasticity with damage, and incorporated environmental effects.

- Outcome/Impact: Created a robust model for simulating advanced material responses, published in Computer Methods in Applied Mechanics and Engineering. Showcased seamless switching between physics-based and ML models.

- DOI: 10.1016/j.cma.2023.116293

- Repository: [Link to Project Repository]

2. Deep Learning-Based Thermodynamically Consistent Material Model (Published in CMAE)

- Objective: Proposed a physics-informed deep learning (DL) constitutive model for epoxy composites that enforces thermodynamic principles, using experimental data to predict material behavior under diverse ambient conditions (temperature, moisture, nanoparticle volume fraction).

- Tech Stack: Python, Deep Learning (LSTM, Feed-Forward Neural Networks), Experimental Data Analysis.

- Key Contributions: Designed a DL architecture combining LSTM and FFNNs to predict internal variables and free-energy, ensuring thermodynamic consistency. Trained solely on experimental data to capture complex, nonlinear, temperature- and moisture-dependent responses.

- Outcome/Impact: Developed a novel DL model capable of accurately predicting material behavior while adhering to thermodynamic laws, published in Computer Methods in Applied Mechanics and Engineering.

- DOI: 10.1016/j.cma.2024.117038

- Repository: [Link to Project Repository]

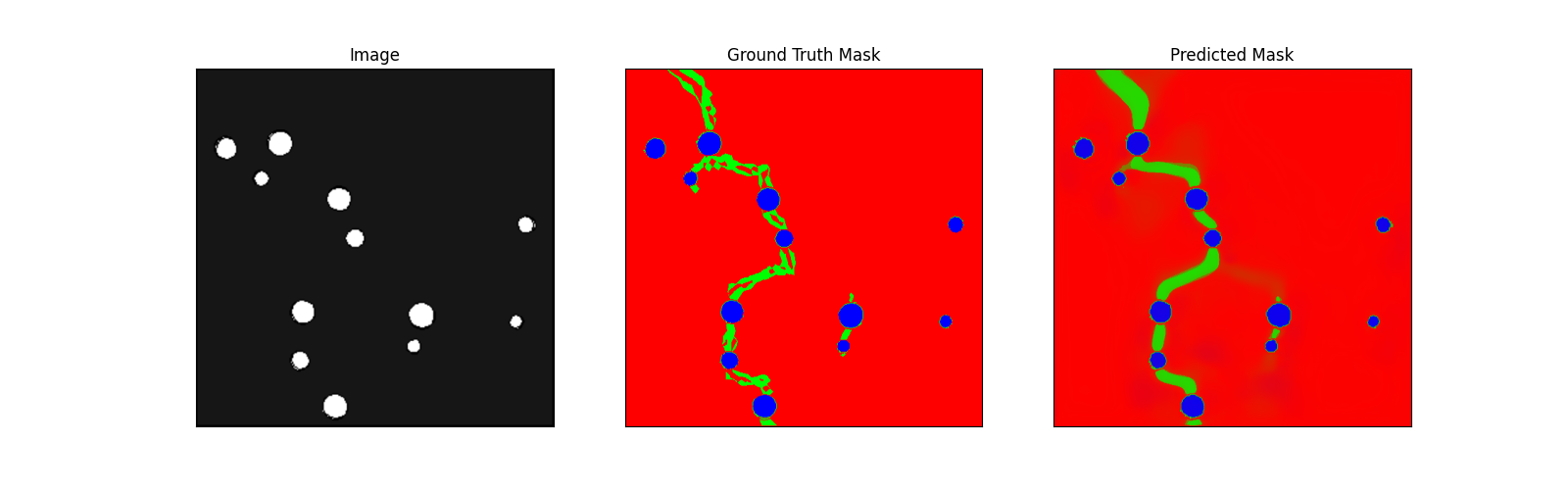

3. Crack Detection in Electromechanical Materials using U-Net (Computer Vision)

- Objective: Applied deep learning (U-Net with ResNet backbones) for semantic segmentation of crack propagation in materials under electromechanical stress, analyzing phase-field and electrical potential patterns from FEM simulations.

- Tech Stack: Python, TensorFlow, Keras, OpenCV, ABAQUS (for data generation).

- Key Contributions: Implemented a multi-class semantic segmentation pipeline for pixel-level crack detection, utilized transfer learning, and automated hyperparameter tuning. Compared phase-field and electrical potential visualization methods.

- Outcome/Impact: Achieved high precision (IoU > 0.95) in detecting and classifying cracks/defects, offering a significant improvement over traditional methods.

- Repository: Computer-Vision-Crack-Detection

4. Predictive Maintenance System for Manufacturing using machine learning

- Objective: Developed a machine learning system to predict 5 different types of equipment failures (TWF, HDF, PWF, OSF, No Failure) in manufacturing environments using sensor data, enabling proactive maintenance.

- Tech Stack: Python, Scikit-learn, XGBoost, Pandas, Matplotlib, Seaborn.

- Key Contributions: Performed comprehensive EDA, extensive feature engineering, implemented multi-class classification models, and created a configurable pipeline with advanced visualizations. Utilized the AI4I 2020 Predictive Maintenance Dataset.

- Outcome/Impact: Built a system achieving strong predictive performance across various failure types, providing a practical solution for reducing downtime in industrial settings.

- Repository: Predictive_Maintenance

5. ABAQUS Multiphysics Diffusion UEL

- Objective: Implemented a User Element (UEL) for ABAQUS to simulate coupled hydro-mechanical behavior of moisture diffusion in polymer materials, capturing stress-assisted transport mechanisms.

- Tech Stack: Fortran, ABAQUS (UEL Development), MATLAB (for visualization).

- Key Contributions: Developed a 20-node quadratic hexahedral UEL for multiphysics coupling (stress-assisted diffusion), enabling monolithic solution of mechanical and diffusion fields. Provided MATLAB tools for post-processing.

- Outcome/Impact: Created a flexible tool for advanced simulation of moisture diffusion in polymers under mechanical stress, applicable to aerospace, marine, and electronics industries.

- Repository: ABAQUS-Multiphysics-Diffusion-UEL

📊 My GitHub Stats

📈 Contribution Graph

📫 How to Reach Me

- Email:

betimbahtiri@outlook.de - LinkedIn: Dr.-Ing. Betim Bahtiri

- Feel free to open an issue on any of my repositories if you have questions or want to collaborate!

- The projects are not related to my current employer !

Thanks for stopping by! Connect with me to explore collaborations and innovative ideas.