New issue

Have a question about this project? Sign up for a free GitHub account to open an issue and contact its maintainers and the community.

By clicking “Sign up for GitHub”, you agree to our terms of service and privacy statement. We’ll occasionally send you account related emails.

Already on GitHub? Sign in to your account

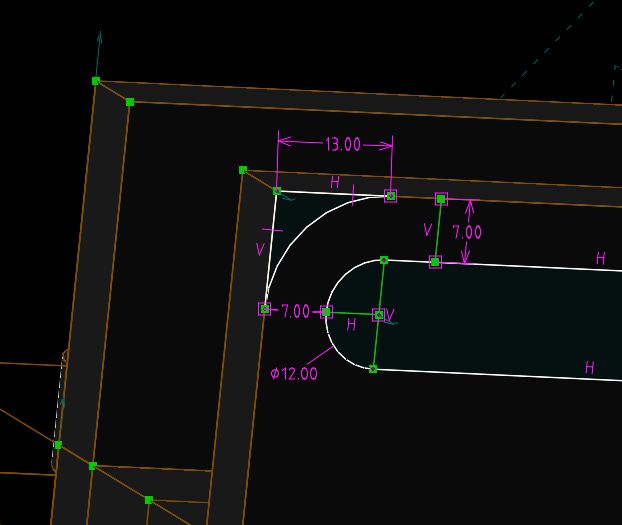

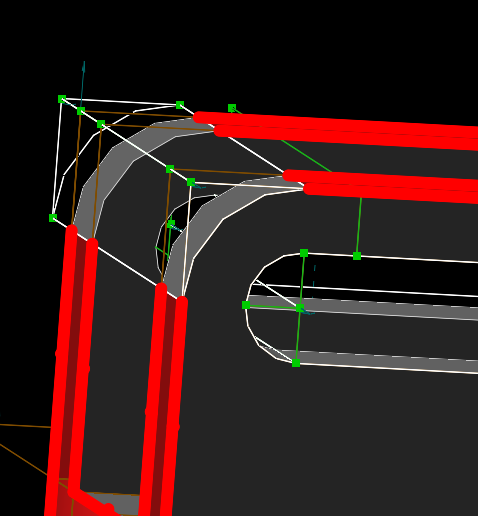

Big Red lines even if "force NURBS surface to triangle mesh" and export stl #1298

Comments

|

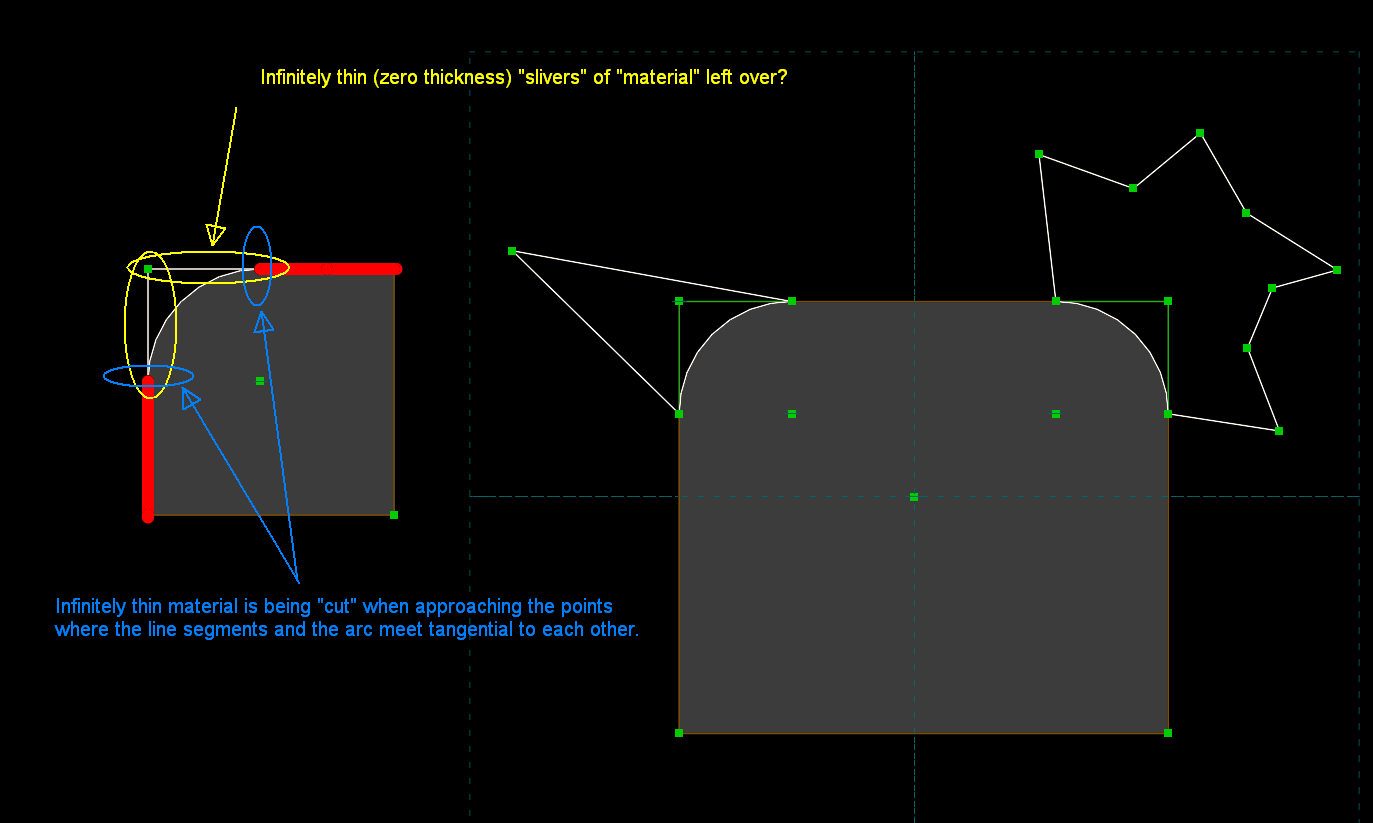

It is a known problem #1291. Make the straight parts (corner) of the cutting ark sketch stick out of the part by a bit (instead of coinciding with the corner) - it will solve your problem. In other words the 13mm line segments and the ark should not meet tangent to each other at the edge of the part. Instead there should be two short line segments perpendicular to the arc ends (and the part) sticking out. |

|

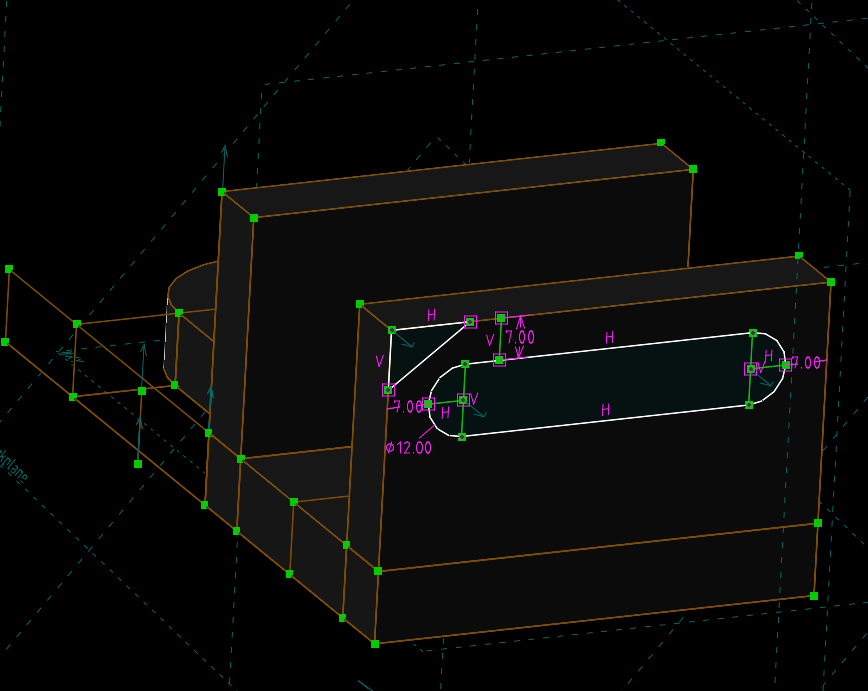

You did it in a way that is more complicated than needed. Here is what I would do: The failing case asks the software to make two "complicated" (for an algorithm) decisions:

To avoid this I just used two construction lines to position the arc and moved the two lines forming the sketch to the outside. Another hint - make the extrusion with the "difference" operation "two-sided" to avoid asking SolveSpace to solve a similar singularity problem where the "front" faces of the two solids coincide (it does usually handle it OK). The test model: Some previous explanations on the topic: The issue collecting all such problems: |

The Read these two sections of the reference: |

System information

Hello,

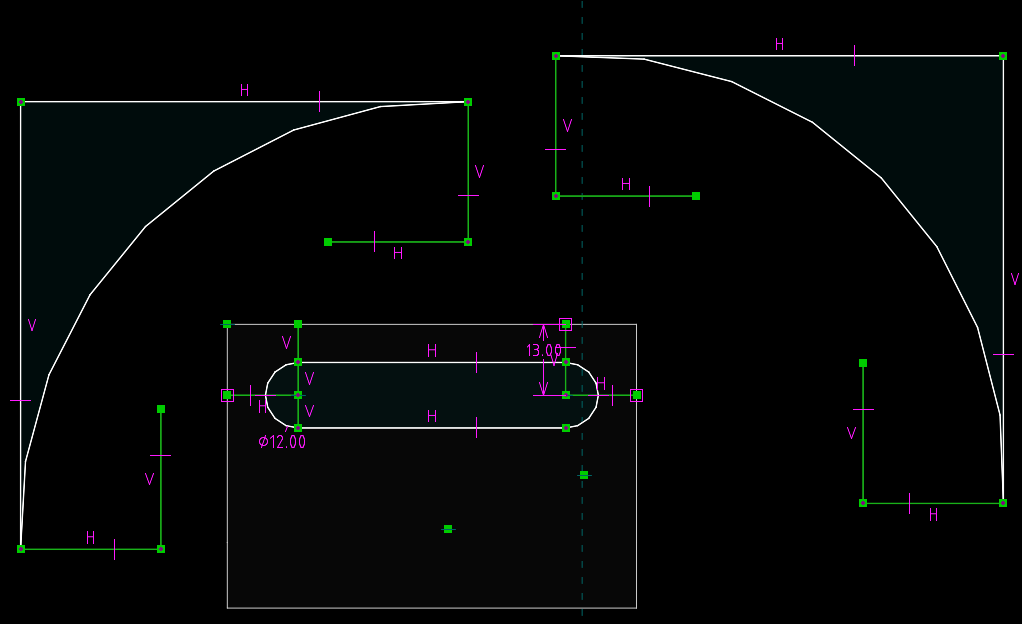

from this it is ok

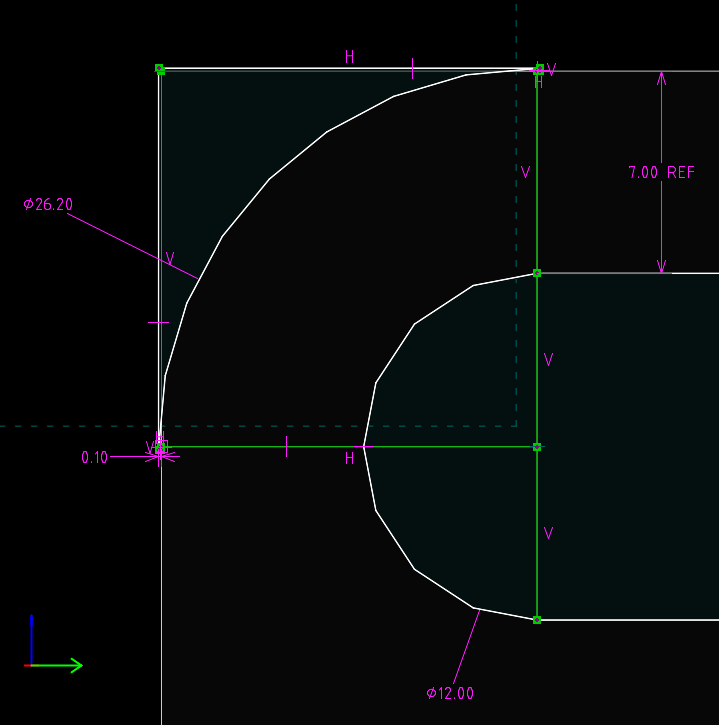

but from this arc version

i get

and it is ok when i do "force NURBS surface to triangle mesh" => no red lines

but when i export triangle maillage

i get

I am furious and disappointed (LOL).

Thanks

The text was updated successfully, but these errors were encountered: