| icon |

|---|

material/cog |

The board dimensions are illustrated in the drawing below; the listed measurements are in inches.

[{ width="400" }](./assets/img/hookup_guide/dimensions.png "Click to enlarge") [Board dimensions (PDF)](./assets/board_files/dimensions.pdf) for the IoT Motor Driver board, in inches.??? tip "Need more measurements?" For more information about the board's dimensions, users can download the eagle files for the board. These files can be opened in Eagle and additional measurements can be made with the dimensions tool.

??? info ":octicons-download-16:{ .heart } Eagle - Free Download!"

Eagle is a [CAD]("computer-aided design") program for electronics that is free to use for hobbyists and students. However, it does require an account registration to utilize the software.

<center>

[Download from<br>:autodesk-primary:{ .autodesk }](https://www.autodesk.com/products/eagle/free-download "Go to downloads page"){ .md-button .md-button--primary width="250px" }

</center>

??? info ":straight_ruler: Dimensions Tool"

This video from Autodesk demonstrates how to utilize the dimensions tool in Eagle, to include additional measurements:

<center>

<div class="video">

<iframe src="https://www.youtube.com/embed/dZLNd1FtNB8" title="EAGLE Dimension Tool" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture" allowfullscreen></iframe>

</div>

{ .qr }

</center>

The USB connector is provided to power and program the board. For most users, it will be the primary programming interface for the ESP32 module on the IoT Motor Driver board.

[{ width="400" }](./assets/img/hookup_guide/usb_connector.jpg "Click to enlarge") USB-C connector on the IoT Motor Driver board.The IoT Motor Driver only requires 5V to power all of the board's components. The simplest method to power the board is through the USB-C connector. Alternatively, the 3V3 pin can be used to supply power to any of the components, except the motor driver.

Below, is a general summary of the power circuitry on the board:

3V3- Provides a regulated 3.3V from the USB (5V) power to the board, excluding the TMC6300 motor driver.3V3_A- Provides a regulated 3.3V from the USB (5V) power to only the TMC6300 motor driver.- The motor driver will not function without power from the USB connector.

- The 3.3V AP63357 LDO regulator can source up to 3.5A.

VUSB- The voltage from the USB-C connector, usually 5V.- Power source for the entire board.

- Powers the two 3.3V voltage regulators (AP2112 and AP63357).

- Features reverse current protection and a thermal fuse.

MEAS- These pins can be used to measure the current being drawn through the USB connector (see the Jumpers section).

- Power source for the entire board.

GND- The common ground or the 0V reference for the voltage supplies.- Qwiic Connector - Provides a regulated 3.3V voltage to the Qwiic devices.

!!! info For more details, users can reference the schematic and the datasheets of the individual components on the board.

??? warning "Motor Voltage" The Gimbal Stabilizer Motor has an operating voltage range of 6 - 8V. However, we have found that it still functions properly with only 3.3V provided by the IoT Motor Driver board.

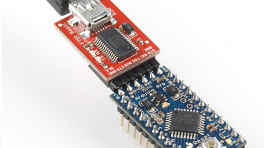

The CH340 allows the ESP32-WROOM to communicate with a computer/host device through the board's USB-C connection. This allows the board to show up as a device on the serial (or COM) port of the computer. Users will need to install the latest drivers for the computer to recognize the board (see Software Overview section).

The brains of the IoT Motor Driver, is an ESP32-WROOM module with 16MB of flash memory. Espressif's ESP32-WROOM module is a versatile, WiFi+BT+BLE MCU module that targets a wide variety of applications. At the core of this module is the ESP32-D0WDQ6 system on a chip (SoC) which is designed to be both scalable and adaptive microcontroller. Its laundry list of features include:

- Features:

* Xtensa® Dual-Core 32-bit LX6 Microprocessor *(up to 240MHz)*

* 448KB ROM and 520KB SRAM

* 16MB of Embedded SPI Flash Storage

* Cryptographic Hardware Accelerators

* AES, SHA2, ECC, RSA-4096

* Integrated 802.11 b/g/n WiFi 2.4GHz Transceiver *(up to 150Mbps)*

* Integrated dual-mode Bluetooth (Bluetooth v4.2 and BLE)

* 26 GPIO *(including strapping pins)*

* 8x Capacitive Touch Electrodes

* Operating Voltage: **3.0 to 3.6V**

* WiFi: 380mA *(peak)*

* Light-Sleep: 800µA

* Deep-Sleep: 10 - 150µA

- [{ width="400" }](./assets/img/hookup_guide/esp32_module.jpg "Click to enlarge") ESP32-WROOM module on the IoT Motor Driver.

!!! warning Users should be aware of the following nuances and details of this board

* The ESP32-WROOM is only compatible with **2.4GHz WiFi** networks; it will not work on the 5GHz bands.

* For details on the boot mode configuration, please refer to [section **3.3 Strapping Pins**](./assets/component_documentation/esp32-wroom-32e_datasheet_en.pdf#8) of the ESP32-WROOM module datasheet.

!!! info The ESP32-WROOM module has various power modes:

* **Active** - The chip radio is powered on. The chip can receive, transmit, or listen.

* **Modem Sleep** - The CPU is operational and the clock is configurable. The Wi-Fi/Bluetooth

baseband and radio are disabled.

* **Light Sleep** - The CPU is paused. The RTC memory and RTC peripherals, as well as the ULP

coprocessor are running.

* **Deep Sleep** - Only the RTC memory and RTC peripherals are powered on. The ULP coprocessor is functional.

* **Hibernation** - Only one RTC timer on the slow clock and certain RTC GPIOs are

active.

* **Off** - Chip is powered off

*For more information on the power management of the ESP32-WROOM module, pleaser refer to **Section 3.7** and **Tables: 8 and 17** of the [ESP32 SoC Datasheet](./assets/component_documentation/esp32_soc_datasheet_en.pdf).*

For users interested in debugging their code, the JTAG pins are broken out on the board. However, the debugging feature is only available through the ESP-IDF.

TMS:GPIO 14TDI:GPIO 12TCK:GPIO 13TDO:GPIO 15

Users can manually force the board into the serial bootloader with the ++"BOOT"++ button. Please, refer to the Boot Button section below for more information.

!!! warning Users should be aware of the following nuances of this board

* ⚡ All the GPIO on the IoT Motor Driver are **3.3V** pins.

* The I/O pins are <strong>not 5V-tolerant</strong>! To interface with higher voltage components, a **[logic level adapter](https://learn.sparkfun.com/tutorials/bi-directional-logic-level-converter-hookup-guide)** is recommended.

* ⚡ There are electrical limitations to the amount of current that the ESP32-WROOM module can sink or source. For more details, check out the [ESP32-WROOM module datasheet](./assets/component_documentation/esp32-wroom-32e_datasheet_en.pdf).

* There are some limitations to the ADC performance, see the <b>Note</b> from the [**ADC Characteristics** section of the ESP32 SoC datasheet](./assets/component_documentation/esp32_soc_datasheet_en.pdf).

The ESP32-WROOM module has 26 multifunctional GPIO, of which, 16 I/O pins are used to interface with motor driver, sensors, and status LED on the board. Additionally, 13 I/O pins are broken out to PTH pins and the users buttons. All of the IoT Motor Driver pins have a .1" pitch spacing for headers.

While all of the GPIO pins are capable of functioning as digital I/O pins, various pins can have additional capabilities with the pin multiplexing feature of the ESP32 SoC. For more technical specifications on the I/O pins, please refer to the ESP32 SoC datasheet.

- 13x 12-bit analog to digital converter (ADC) channels

- 3x UARTs (only two are configured by default in the Arduino IDE, one UART is used for bootloading/debug)

- 3x SPI (only one is configured by default in the Arduino IDE)

- 2x I2C (only one is configured by default in the Arduino IDE)

- 2x I2S Audio

- 2x digital-to-analog converter (DAC) channels

- 16x 20-bit PWM outputs

- 8x Capacitive Touch Inputs

!!! info Users should be aware of the following limitations for the board in the Arduino IDE.

* Not all of the features, listed above, are available in the Arduino IDE. For the full capabilities of the ESP32, the Espressif IDF should be utilized.

* Only one I<sup>2</sup>C bus is defined.

* Only two UART interfaces are available.

* **UART (USB):** `Serial`

* **`RX`/`TX` Pins:** `Serial1`

* Only one SPI bus is defined.

This development board features several components operating together to create an IoT device. Their connections are shown in the diagram below and their operations are listed in the boxes below. For more details on each component, please refer to the sections below.

[{ width="400" }](./assets/img/hookup_guide/block_diagram.png "Click to enlarge") Block diagram of the IoT Motor Driver board's peripherals.-

Inputs

- TMC6300 Motor Driver

- Diagnostic Pin

- TMAG5273 Hall-Effect Sensor

- INA240 Current-Sense Amplifier

- MCP6021 Operational Amplifier

- User Buttons

- TMC6300 Motor Driver

-

Outputs

- TMC6300 Motor Driver

- Half-Bridge Pins

- Standby Pin

- RGB Status LED

- TMC6300 Motor Driver

There are several pins that have special functionality in addition to general digital I/O. These pins and their additional functions are listed in the tabs below. For more technical specifications on the I/O pins, you can refer to the schematic, ESP32-WROOM module datasheet, ESP32 SoC datasheet, and documentation for the ESP32 Arduino core.

=== "Digital I/O Pins"

Any GPIO pin on the ESP32-WROOM module can function as a digital I/O (input or output). However, users will need to declare the pinMode() (link) in the setup of their sketch (programs written in the Arduino IDE) to configure a pin as an input or an output.

<div class="grid cards col-2" markdown>

- **Inputs**

---

When configured properly, an <b>input</b> pin will be looking for a <b>HIGH</b> or <b>LOW</b> state. <b>Input</b> pins are <b>High Impedance</b> and takes very little current to move the input pin from one state to another.

<center>

| **`DIAG` *(TMC6300)*** | `GPIO 34` |

| :--------------------- | :-------- |

| **`INT` *(TMAG5273)*** | `GPIO 04` |

| **Button ++"13"++** | `GPIO 13` |

| **Button ++"14"++** | `GPIO 14` |

</center>

- **Outputs**

---

When configured as an <b>output</b> the pin will be at a <b>HIGH</b> or <b>LOW</b> voltage. <b>Output</b> pins are <b>Low Impedance</b>: This means that they can provide a relatively substantial amount of current to other circuits.

<center>

| **`VIO` *(TMC6300)*** | `GPIO 05` |

| :-------------------- | :-------- |

| **WS2812** | `GPIO 02` |

</center>

!!! warning

**⚡** There are electrical limitations to the amount of current that the ESP32-WROOM module can sink or source. For more details, check out the <a href="./assets/component_documentation/esp32-wroom-32e_datasheet_en.pdf">ESP32-WROOM module datasheet</a>.

</div>

!!! tip

Pins cannot be configured to operate simultaneously as an input and output, without implementing the pin as an interrupt.

=== "Analog Inputs"

The ESP32-WROOM module provides a 12-bit ADC input on thirteen of its I/O pins. This functionality is accessed in the Arduino IDE using the analogRead(pin) function. (The available ADC pins are highlighted in the image below.)

<center>

| **Current Sensor** | INA240 *(`U`)* | INA240 *(`V`)* | INA240 *(`W`)* | MCP6021 |

| :----------------- | :------------: | :------------: | :------------: | :-------: |

| **Analog Input** | `GPIO 35` | `GPIO 36` | `GPIO 39` | `GPIO 32` |

</center>

!!! info

By default, in the Arduino IDE, `analogRead()` returns a 10-bit value. To change the resolution of the value returned by the `analogRead()` function, use the [`analogReadResolution(bits)` function](https://www.arduino.cc/reference/en/language/functions/zero-due-mkr-family/analogreadresolution/).

!!! tip

To learn more about analog vs. digital signals, check out this great [tutorial](https://learn.sparkfun.com/tutorials/analog-vs-digital).

<div class="grid cards col-4" markdown align="center">

- <a href="https://learn.sparkfun.com/tutorials/89">

<figure markdown>

</figure>

---

**Analog vs. Digital**</a>

</div>

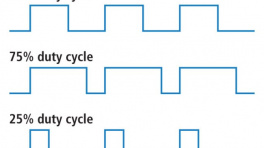

=== "PWM & Analog (DAC) Outputs"

The ESP32-WROOM module supports up to sixteen channels of 20-bit PWM (Pulse Width Modulation) outputs on any of its I/O pins. This is accessed in the Arduino IDE using the analogWrite(pin, value) function. (Any I/O pin can be used for the PWM outputs; the available DAC pins, with true analog outputs, are highlighted in the image below.)

[{ width="300" align="left" }](./assets/img/hookup_guide/pins_dac.jpg)

<center>

| **Motor Driver** | `UH` | `UL` | `VH` | `VL` | `WH` | `WL` |

| :--------------- | :-------: | :-------: | :-------: | :-------: | :-------: | :-------: |

| **PWM Output** | `GPIO 16` | `GPIO 17` | `GPIO 18` | `GPIO 23` | `GPIO 19` | `GPIO 33` |

</center>

!!! info

By default, in the Arduino IDE, `analogWrite()` accepts an 8-bit value. To change the resolution of the PWM signal for the `analogWrite()` function, use the [`analogWriteResolution(bits)` function](https://www.arduino.cc/reference/en/language/functions/zero-due-mkr-family/analogwriteresolution/). *(The PWM output is not a true analog signal.)*

!!! tip

To learn more about pulse width modulation (PWM), check out this great [tutorial](https://learn.sparkfun.com/tutorials/pulse-width-modulation).

<div class="grid cards col-4" markdown align="center">

- <a href="https://learn.sparkfun.com/tutorials/51">

<figure markdown>

</figure>

---

**Pulse Width Modulation**</a>

</div>

=== "Serial Pins"

The ESP32-WROOM module provides three UART ports. By default, the UART port for the USB connection (Serial) and the labeled UART I/O pins on the board (Serial1) can be accessed through the Arduino IDE using the serial communication class.

!!! info

By default, in the Arduino IDE, the **<Dev Board Name>** board definition supports:

* `Serial` - **UART (USB)**

* `Serial1` - **Pins: `RX`/`TX` (`GPIO 16`/`GPIO 17`)**

??? note

* The `GPIO 16` and `GPIO 17` pins of `Serial1` are already dedicated to the `UH`/`UL` half-bridge on the TMC63000 motor driver and are not broken out for users to access.

* In order to utilize the serial communication on the strapping pins, users will need to create a custom serial port object and declare which pins to access.

!!! tip

To learn more about serial communication, check out this great [tutorial](https://learn.sparkfun.com/tutorials/serial-communication).

<div class="grid cards col-4" markdown align="center">

- <a href="https://learn.sparkfun.com/tutorials/8">

<figure markdown>

</figure>

---

**Serial Communication**</a>

</div>

!!! tip

We have noticed that with the ESP32 Arduino core, `Serial.available()` does not operate instantaneously. This is due to an interrupt triggered by the UART, to empty the FIFO when the <b>`RX`</b> pin is inactive for two byte periods:

* At 9600 baud, `hwAvailable` takes [`number of bytes received` + 2] x 1 ms = <b>11 ms</b> before the UART indicates that data was received from: `\r\nERROR\r\n`.

* At 115200 baud, `hwAvailable` takes [`number of bytes received` + 2] x .087 ms = <b>~1 ms</b> before the UART indicates that data was received from: `\r\nERROR\r\n`.

*For more information, please refer to this [chatroom discussion](https://gitter.im/espressif/arduino-esp32?at=5e25d6370a1cf54144909c85).*

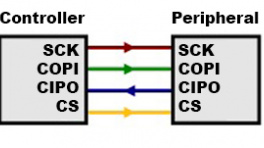

=== "SPI Pins"

The ESP32-WROOM module provides three SPI buses. By default, in the Arduino IDE, the SPI class is configured to utilize pins GPIO 18 (SCK), GPIO 19 (POCI), GPIO 23 (PICO). In order to utilize the other SPI ports or objects, users will need to create a custom SPI object and declare which pins to access.

!!! info

To comply with the latest [OSHW](https://www.oshwa.org/) design practices, we have [adopted the new SPI signal nomenclature](https://www.sparkfun.com/spi_signal_names) (**SDO**/**SDI** and **PICO**/**POCI**). The terms Master and Slave are now referred to as Controller and Peripheral. The `MOSI` signal on a controller has been replaced with `SDO` or `PICO`. Please refer to this [announcement on the decision to deprecate the **MOSI**/**MISO** terminology and transition to the **SDO**/**SDI** naming convention](https://www.oshwa.org/a-resolution-to-redefine-spi-signal-names).

<center>

| **SCK** | `GPIO 18` (`SCK`) |

| :------------------ | :----------------- |

| **SDI** or **POCI** | `GPIO 19` (`MISO`) |

| **SDO** or **PICO** | `GPIO 23` (`MOSI`) |

| **CS** | `GPIO 5` (`SS`) |

</center>

??? note

* The `GPIO 18`,`GPIO 19`, and `GPIO 23` pins of the `SPI` bus are already dedicated to the `VH`/`WH`/`VL` MOSFETs on the TMC63000 motor driver and are not broken out for users to access.

* The `CS` pin associated with `GPIO 05` is also already dedicated to the `STBY` pin of the TMC63000 motor driver and is not broken out for users to access.

!!! tip

To learn more about the serial peripheral interface (SPI) protocol, check out this great [tutorial](https://learn.sparkfun.com/tutorials/serial-peripheral-interface-spi).

<div class="grid cards col-4" markdown align="center">

- <a href="https://learn.sparkfun.com/tutorials/16">

<figure markdown>

</figure>

---

**Serial Peripheral Interface (SPI)**</a>

</div>

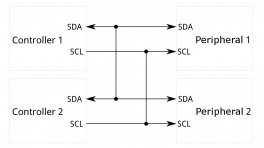

=== "I2C Pins"

The ESP32-WROOM module module can support up to two I2C buses. By default, in the Arduino IDE, the Wire class is configured to utilize pins GPIO 21 (SDA) and GPIO 22 (SCL). These pins share the same I2C bus with the Qwiic connector and TMAG5273 hall-effect sensor. In order to utilize the other I2C ports, users will need to create a custom Wire object and declare which pins to access.

<div class="grid cards col-2" markdown>

- <center>

**I<sup>2</sup>C Pins**

| **SCL** | `GPIO 22` |

| :------ | :-------- |

| **SDA** | `GPIO 21` |

</center>

---

TMAG5273 I<sup>2</sup>C Address:

* **0x35 *(Default)*** (7-bit)

* 0x6A (write)/0x6B (read)

- <figure markdown>

[{ width="400" }](./assets/img/hookup_guide/i2c_connections.jpg "Click to enlarge")

<figcaption markdown>Default I<sup>2</sup>C bus connections for the IoT Motor Driver.</figcaption>

</figure>

</div>

!!! tip

To learn more about the inter-integrated circuit (I<sup>2</sup>C) protocol, check out this great [tutorial](https://learn.sparkfun.com/tutorials/i2c).

<div class="grid cards col-4" markdown align="center">

- <a href="https://learn.sparkfun.com/tutorials/82">

<figure markdown>

</figure>

---

**Inter-Integrated Circuit (I<sup>2</sup>C)**</a>

</div>

The TMC6300 from Trinamic Motion Control, part of Analog Devices, is a low voltage, 3-Phase BLDC/PMSM motor driver utilizing separate high-side and low-side control signals for its three half-bridges.

- Features:

* VIN: 2.0V to 11.0V

* Operating current: 7mA

* Standby current: 30nA

* VOUT: 1.8V

* 3 Half-Bridges

* 3 High-side MOSFETs

* 3 Low-side MOSFETs

* I/O Supply Voltage Input

* Diagnostic Output

* Overtemperature Protection

* Shutdown Temperature: 150°C

* Typical Power Dissipation: 1W

* Short Protection

!!! info

For more details, please refer to the [TMC6300 datasheet](./assets/component_documentation/TMC6300.pdf).

-

[{ width="400" }](./assets/img/hookup_guide/TMC6300.jpg "Click to enlarge")

TMC6300 chip on the IoT Motor Driver.

For users unfamiliar with the TMC6300 motor driver, please check out our hookup guide below.

-

TMC6300 BLDC Motor Driver Hookup Guide

-

The TMC6300 features high-side and low-side MOSFET pairs of the three available half-bridges which control the commutation of the three motor phases.

[{ width="300"}](./assets/img/hookup_guide/block_diagram-half_bridges.png "Click to enlarge") 6 PWM control of a 3-phase motor commutation.(Source: Modified from the [Block commutation vs. FOC in power tool motor control](https://www.infineon.com/dgdl/Infineon-Motor_power_tool_Block_Commutation_vs_FOC-ApplicationNotes-v01_00-EN.pdf?fileId=5546d4626eab8fbf016ed37fee474a65) application note)

=== "Input" The electronic commutation sequence for these MOSFETs will depend on the motor that is connected. For most cases, users will provide a PWM signal to each of these pins. These are active-high pins.

<center>

| ESP32-WROOM | `16` | `17` | `18` | `23` | `19` | `33` |

| :----------- | :--: | :--: | :--: | :--: | :--: | :--: |

| Motor Driver | `UH` | `UL` | `VH` | `VL` | `WH` | `WL` |

</center>

??? info "Active High"

By pulling the pin high, the MOSFET will enable power to flow through that section of the half-bridge.

=== "Output" With the electronic commutation sequence provided to the half-bridges, the output motor phases will drive a connected motor.

<figure markdown>

[{ width="300"}](./assets/img/hookup_guide/motor2.jpg "Click to enlarge")

<figcaption markdown>

The three motor phase outputs (`U`/`V`/`W`) from the TMC6300 are used to drive the gimbal motor, attached through the JST connector.

</figcaption>

</figure>

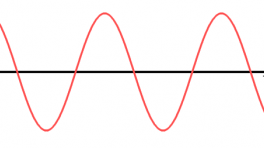

The TMC6300 relies on an electrical commutation sequence/signal to drive the motor phases to a BLDC or PMSM motor. The commutation signals for these motors are trapezoidal for BLDC motors and sinusoidal for PMSM motors.

- [](./assets/img/hookup_guide/commutation-trapezoidal.png "Click to enlarge") Trapezoidal motor commutation.

- [](./assets/img/hookup_guide/commutation-sinusoidal.png "Click to enlarge") Sinusoidal motor commutation.

!!! tip "Gimbal Motor" Based on measuring the output from one of the coils, our gimbal motor is a PMSM and would require a sinusoidal waveform to drive the motor. It should be noted that a trapezodial waveform can probably be used; however, users may notice effects such as cogging.

<figure markdown>

[{ width="300" }](./assets/img/hookup_guide/pwm-sine_wave.png "Click to enlarge")

<figcaption markdown>

Sinusoidal PWM signal.<br>

(Source: [Demystifying BLDC motor commutation: Trap, Sine, & FOC](https://www.ti.com/lit/ml/slyp711/slyp711.pdf))

</figcaption>

</figure>

For a trapezoidal signal, the high-side (HS) and low-side (LS) MOSFETs, can just be driven high or low. However, in order to approximate a sinusoidal signal, a progressively varying PWM signal must be provided with all six signals in sync with each other.

In it's default configuration, the VIO pin is used to enable the motor driver and set the logic level voltage of the TMC6300 inputs. However, the VIO pin also operates as a standby pin when it is pulled LOW. In standby, the TMC6300 resets and sits in standby mode.

Users can control the VIO pin with GPIO 05 on the ESP32-WROOM module, to reset the TMC6300 or put it in standby mode.

The diagnostic pin is triggered based on different faults (i.e. shorts and overtemperature) detected by the IC. By default, the status will be indicated by the, green diagnostic, DIAG LED and will remail LOW until triggered. Once triggered, users will need to disable and reset the TMC6300 or power cycle the board.

Users can monitor the diagnostic pin with GPIO 34 on the ESP32-WROOM module, to determine if the TMC6300 need to be reset to clear a fault.

The current sense pin is the foot point of the U and V half-bridges, with a 0.12Ω resistor attached. Users can measure the voltage across the resistor to determine the current flowing to the motor (see the Low-side Op Amp - MCP6021 section below).

The TMAG5273 from Texas Instruments, is a 3-axis hall-effect sensor utilizing a 12-bit ADC. For more information, please refer to the TMAG5273 datasheet.

-

Features:

- I2C Address:

- 0x35 (Default) (7-bit)

- 0x6A (write)/0x6B (read)

- Magnetic Range (Sensitivity):

- ± 40mT (820 LSB/mT)

- ± 80mT (410 LSB/mT)

- Magnetic Drift: 5%

- Rotational Accuracy: ± 0.5°/360° rotation

- Voltage Range: 1.7 - 3.6V

- Sleep: 5nA

- Wake-Up/Sleep: 1µA

- Active: 2.3mA

- Operating Temperature: –40 - 125°C

- Integrated temperature compensation

- Configurable sample rate

- I2C Address:

-

[{ width="400" }](./assets/img/hookup_guide/TMAG5273.jpg "Click to enlarge")

The TMAG5273 hall-effect sensor on the IoT Motor Driver.

!!! tip "Magnetic Axes" On the IoT Motor Driver, users will primarily be interested in magnetic field of the X-Y axes to measure the position of the gimbal motor.

<figure markdown> [{ width="400" }](./assets/img/hookup_guide/TMAG5273_axes.png "Click to enlarge") <figcaption markdown>The magnetic axes of TMAG5273 hall-effect sensor.</figcaption> </figure>

!!! info For more details, please refer to the TMAG5273 datasheet.

The interrupt pin of the TMAG5723 can be configured in different modes to utilize either the INT or SCL pins.

- No interrupt

- Interrupt through

INT - Interrupt through

INTexcept when I2C busy - Interrupt through

SCL - Interrupt through

SCLexcept when I2C busy

!!! tip

We recommend utilizing the default INT pin to trigger interrupts; as it is already connected to GPIO 04 of the ESP32-WROOM module.

??? warning "Bus Contention"

Texas Instruments does not recommend sharing the I<sup>2</sup>C bus with multiple devices when using the `SCL` pin for the interrupt function. The `SCL` interrupt can potentially corrupt the transactions with other devices, when present on the same I<sup>2</sup>C bus.

!!! note

The TMAG5273 is programmed to detect a magnetic threshold in wake-up or sleep mode. Once the magnetic threshold cross is detected, the device asserts a latched interrupt signal through the INT pin, and goes back to stand-by mode. The interrupt latch is cleared through the SCL pin.

There are two different types of Op Amps on the board to amplify the input voltage for the current measurements.

- The INA240 is used for the in-line current measurements between the TMC6300 and the gimabal motor.

- The MCP6021 is used on the low-side current measurement of the TMC63000's half-bridges.

| Current Sensor | INA240 (U) |

INA240 (V) |

INA240 (W) |

MCP6021 |

|---|---|---|---|---|

| Analog Input | GPIO 35 |

GPIO 36 |

GPIO 39 |

GPIO 32 |

The INA240 from Texas Instruments, is a voltage-output, current-sense amplifier. For more information, please refer to the INA240 datasheet.

- [{ width="400" }](./assets/img/hookup_guide/INA240.jpg "Click to enlarge") The INA240 current-sense amplifier on the IoT Motor Driver.

-

Configured Gain 20 &PlusMn;0.2% Bandwidth 100kHz Voltage Range Range: 2.7 - 5.5V Quiescent Current 1.8 - 2.6mA Operating Temperature –40 - 125°C

The MCP6021 from Microchip Technology, Inc., is a rail-to-rail input and output operational amplifier. The chip . For more information, please refer to the MCP6021 datasheet.

- [{ width="400" }](./assets/img/hookup_guide/MCP6021.jpg "Click to enlarge") The MCP6021 Op Amp on the IoT Motor Driver.

-

Configured Gain 21 Bandwidth 10MHz Voltage Range Range: 2.5 - 5.5V Quiescent Current 0.5 - 1.35mA Operating Temperature –40 - 125°C

There are five status LEDs on the TMC6300 motor driver:

PWR- Power (Red)- Turns on once power is supplied through the USB-C connector

MPWR- Power (Red)- Turns on once power is supplied through the USB-C connector

DIAG- Diagnostics (Green)- Turns on to indicate a fault (see diagnostic pin section)

STBY- Standby (Blue)- Turns on when the motor driver is enabled

- Turns off, when the IC has been reset and the motor driver is in standby mode

STAT- User (RGB)- Controlled through

GPIO 02

- Controlled through

The WS2812 RGB LED is controlled with a 24-bit (GRB) data signal. This indicator is connected to GPIO 02 and the digital output pin from the LED is available through a test point. For more information, please refer to the WS2812C datasheet.

!!! info The latest ESP32 Arduino core, now provides a basic RGB LED driver for a WS2812 (or NeoPixel) LED populated the board. For an example of how to utilize the RGB LED driver check out the BlinkRGB example code, which can be accessed from the File drop down menu (i.e File > Examples > ESP32 > GPIO > BlinkRGB).

There are four buttons on IoT Motor Driver: ++"RST"++, ++"BOOT"++, ++"13"++, and ++"14"++ buttons.

[{ width="400" }](./assets/img/hookup_guide/buttons.jpg "Click to enlarge") Buttons on the IoT Motor Driver.??? tip "Factory Programming" The IoT Motor Driver board will come pre-programmed out of the bag. By default, the ++"13"++/++"14"++ buttons can be used to operate the motor:

* ++"13"++ - Start/Stop the motor's rotation

* ++"14"++ - Switch the direction that the motor is spinning

The ++"RST"++ (reset) button allows users to reset the program running on the ESP32-WROOM module without unplugging the board.

[{ width="400" }](./assets/img/hookup_guide/button_reset.jpg "Click to enlarge") ++"RST"++ button on the IoT Motor Driver.The ++"BOOT"++ button can be used to force the board into the serial bootloader. Holding down the ++"BOOT"++ button, while connecting the board to a computer through its USB-C connector or resetting the board will cause it to enter the Firmware Download mode. The board will remain in this mode until it power cycles (happens automatically after uploading new firmware) or the ++"RST"++ button is pressed.

- Hold the ++"BOOT"++ button down.

- Reset the MCU.

- While unpowered, connect the board to a computer with through the USB-C connection.

- While powered, press the ++"RST"++ button.

- Release the ++"BOOT"++ button.

- After programming is completed, reboot the MCU.

- Press the ++"RST"++ button.

- Power cycle the board.

!!! info

⚡ The ++"BOOT"++ button is also connected to GPIO 0.

The ++"13"++ and ++"14"++ buttons are available for users to configure for their own purposes.

[{ width="400" }](./assets/img/hookup_guide/buttons_user_pins.jpg "Click to enlarge") The user buttons (++"13"++ and ++"14"++) on the IoT Motor Driver.!!! tip "Factory Programming" The IoT Motor Driver board will come pre-programmed out of the bag. By default, these buttons can be used to operate the motor:

* ++"13"++ - Start/Stop the motor's rotation

* ++"14"++ - Switch the direction that the motor is spinning

!!! tip When utilizing the buttons, users should enable the internal pull-up resistors for the GPIO pins.

??? note "Never modified a jumper before?" Check out our Jumper Pads and PCB Traces tutorial for a quick introduction!

<div class="grid cards col-4" markdown align="center">

- <a href="https://learn.sparkfun.com/tutorials/664">

<figure markdown>

</figure>

---

**How to Work with Jumper Pads and PCB Traces**</a>

</div>

There are nine jumpers on the back of the board that can be used to easily modify a hardware connections on the board.

- SHLD - This jumper can be used to disconnect the shield of the USB-C connector from

GND. - MEAS - This jumper can be used to measure the current consumption of the board.

- BYP - This jumper can be used to bypass the thermal fuse.

- LED Jumpers

- PWR - This jumper can be used to remove power from the red, power LED on the AP2112 LDO regulator.

- MPWR - This jumper can be used to remove power from the red, power LED on the AP63357 LDO regulator.

- STBY - This jumper can be used to remove power from the blue, standby LED.

- DIAG - This jumper can be used to remove power from the green, diagnostic LED.

- INT - This jumper can be used to remove the pull-up resistor from the

INTpin of the hall-effect sensor. - I2C - This jumper can be used to remove the pull-up resistors on the I2C bus.

The Qwiic connector and hall-effect sensor are attached to the primary I2C bus. The primary I2C bus for this board utilizes the pin connections, detailed in the table below:

[{ width="400" }](./assets/img/hookup_guide/i2c_connections.jpg "Click to enlarge") I2C bus connections on the IoT Motor Driver.| Connection | VDD |

GND |

SCL |

SDA |

|---|---|---|---|---|

|

Hall-Effect Sensor (TMAG5273) |

3V3 |

GND | GPIO 22 |

GPIO 21 |

| Qwiic Connector | 3V3 |

GND | GPIO 22 |

GPIO 21 |

A Qwiic connector is provided for users to seamlessly integrate with SparkFun's Qwiic Ecosystem. Otherwise, users can connect their I2C devices through the PTH pins broken out on the board.

[{ width="400" }](./assets/img/hookup_guide/i2c_qwiic.jpg "Click to enlarge") Qwiic connector and I2C pins on the IoT Motor Driver.??? tip "What is Qwiic?"

<!-- Qwiic Banner -->

<center>

[{ width=400 }](https://www.sparkfun.com/qwiic)

[{ width=400 }](https://www.sparkfun.com/qwiic)

</center>

---

The [Qwiic connect system](https://www.sparkfun.com/qwiic) is a solderless, polarized connection system that allows users to seamlessly daisy chain I<sup>2</sup>C boards together. Play the video below to learn more about the Qwiic connect system or click on the banner above to learn more about [Qwiic products](https://www.sparkfun.com/qwiic).

<center>

<div class="video">

<iframe src="https://www.youtube.com/embed/x0RDEHqFIF8" title="SparkFun's Qwiic Connect System" frameborder="0" allow="accelerometer; encrypted-media; gyroscope; picture-in-picture" allowfullscreen></iframe>

</div>

</center>

!!! info "Features of the Qwiic System"

=== "No Soldering"

{ align="left" width="90" }

{ align="left" width="90" }

Qwiic cables (4-pin JST) plug easily from development boards to sensors, shields, accessory boards and more, making easy work of setting up a new prototype.

=== "Polarized Connector"

{ align="left" width="90" }

{ align="left" width="90" }

There's no need to worry about accidentally swapping the SDA and SCL wires on your breadboard. The Qwiic connector is polarized so you know you’ll have it wired correctly every time, right from the start.

The PCB connector is part number SM04B-SRSS ([Datasheet](https://cdn.sparkfun.com/assets/parts/1/2/2/8/9/Qwiic_Connector_Datasheet.pdf)) or equivalent. The mating connector used on cables is part number SHR04V-S-B or an equivalent *(1mm pitch, 4-pin JST connector)*.

=== "Daisy Chain-able"

{ align="left" width="90" }

{ align="left" width="90" }

It’s time to leverage the power of the I<sup>2</sup>C bus! Most Qwiic boards will have two or more connectors on them, allowing multiple devices to be connected.