2] PERTINENT INFORMATION GATHERING

Sorting systems are used to bridge between production and packing machinery. sorting system are used to sort items based on various criteria so that they can be packaged according. manual sorting is a time and effort intensive process. Automatic sorting system allow sort fast and efficient sorting of products. To demonstrate the sorting system we develop a PLC based sorting system project that uses pistons with color sensing system powered by PLC control to achieve this functionality.

Fig.1 PLC based product sorting machine

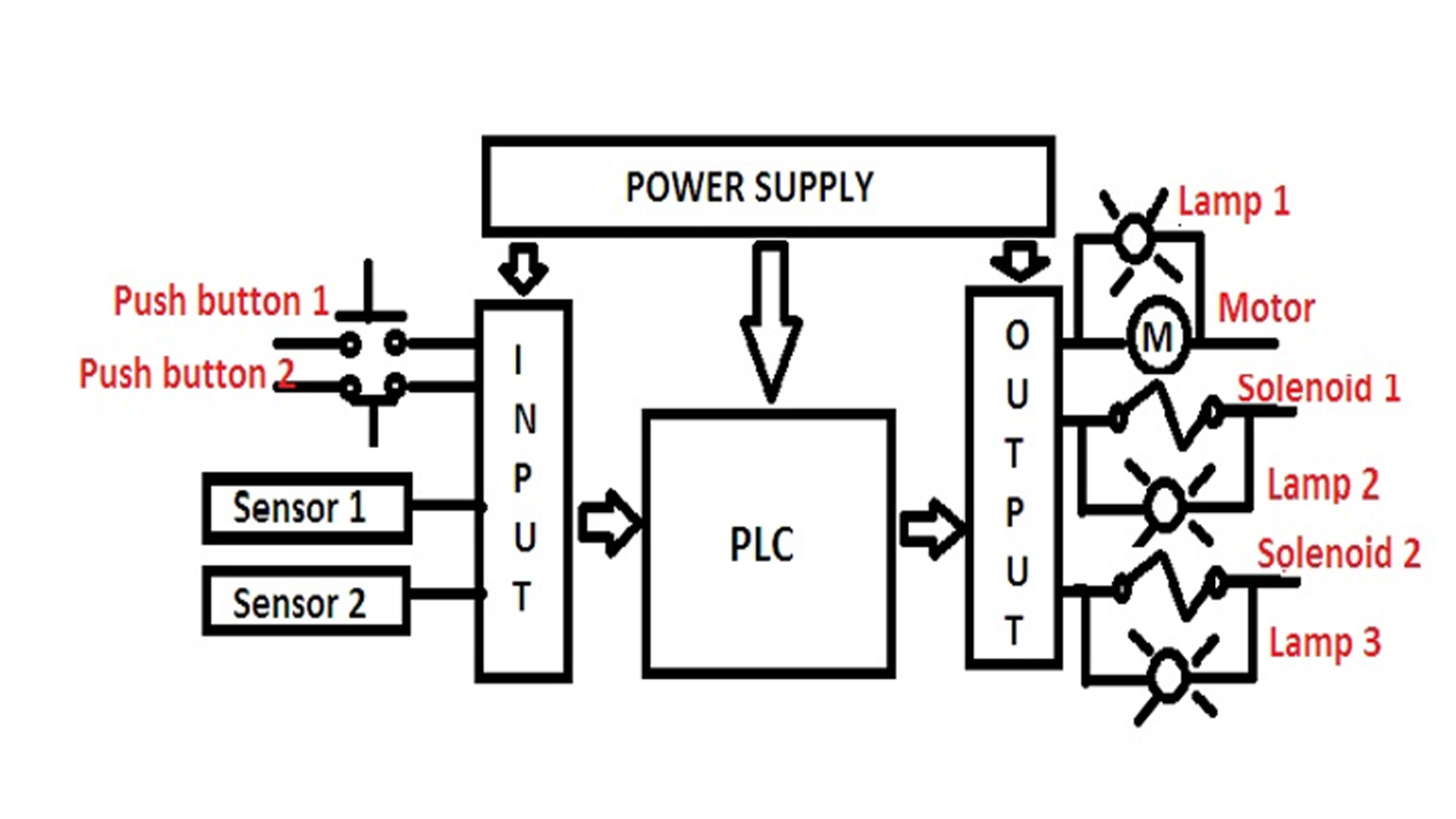

FIG.2. DIAGRAM

| SL.NO | NAME OF COMPONENTS | WORKING PRINCIPLE |

|---|---|---|

| 01 | CONVEYOR BELT | A conveyor belt is the carrying medium of a belt conveyor system. A belt conveyor system is one of the many types of conveyor systems. A conveyor belt consist of two or more pulleys, with a closed loop carrying medium- the conveyor belt-that- rotates about them. |

| 02 | DC MOTOR | An electric motor is an electrical machine that converts electrical energy into mechanical energy. Most electric motors operate through the interaction between the motor's magnetic field and electric current in a wire winding to generate force in the form of torque applied on the motors shaft. |

| 03 | PNEUMATIC ACTUATOR | A Pneumatic actuator control valve actuator converts energy into mechanical motion. The motion can be rotary or linear, depending on the type of motion. |

| 04 | PNEUMATIC PIPES | Pneumatic pipes are systems that propel cylindrical containers through networks of tubes by compressed air or partial vacuum. They are used for transporting solid objects , as opposed to conventional pipelines , which transport fluids. |

| 05 | PNEUMATIC VALVES | Pneumatic valves are one of an array of components responsible for controlling the pressure, rate and amount of air as it moves through a pneumatic system. |

| 06 | PNEUMATC FITTINGS | Pneumatic fittings provide the essential links between tubes, hoses and other components in a pneumatic way. In addition to connecting pneumatic components and stopping the flow of unused ports, miniature fitting are also used to control air flow pressure and directional flow. |

| 07 | Color sensor | A color sensor is a type of photoelectric sensor which emits light from transmitter and then detect## s the light reflected back from the detection object with a receiver. |

| 08 | BRACKETS AND MOUNTS | In mechanical engineering a bracket is any intermediate component for fixing one part to another, usually larger part. |

| 09 | SUPPORTING FRAME | A frame is often a structural systems that supports other components of a physical construction and steal frame that limits the construction's extent. |

| 10 | JOINTS AND FIXTURE | A mechanical joints is a section of a machine which is used to connect one o more mechanical part to another . Mechanical joints may be temporary or permanent , most types are designed to be disassembled. |

| 11 | COUPLING | A coupling is a device used to connect two shafts together at their end for the purpose of transmitting power. The primary purpose of coupling is to join two pieces of rotating equipment while permitting some degree of misalignment or end movement or both. |

| 12 | LADDDER LOGIC | Ladder logic has contacts that makes or break circuits to control coils . Each coil or contact corresponds to the status of a single bit in the programmable controller's memory. |

| 13 | PLC PROGRAMMING | PLC is a special computer device used in industrial control systems. due to its robust construction , exceptional functional features like sequential control , counters and timers , ease of programming , reliable controlling capabilities and ease of hardware usage -this PLC is used as more than a special purpose digital computers in industries as well as in other control system areas. |

- Using automated sorting machine, which reduces a lot of labor cost for companies to manage and store goods by automated sorting

- Secured logistical sorter ,we produce the auto sorting system that has goods sorting secured and correct

- The high sorting efficiency is the biggest advantage of this application of such systems . It plays a important role in storage and retrieval works, making sorting work efficient and warehousing further improved.

It works on the principle of detection of material type initially then identifies the size of material to push it to its destination by using sensor technology. The system consists of a conveyor belt to carry products from one end to collection baskets. It consists a color sensor to sense the type of products using color sense , the system now utilizes 3 pistons with piping and control valves to control their operations. The system is powered by a PLC to control the sorting system. 3 collection baskets are used to collect samples sorted by the pistons mounted parallel to each one . The PLC coordinates with sensors and pistons valves in order to achieve the desired functionality and demonstrate the fully automated product sorting system.

YOUTUBE -[https://youtu.be/-SVn6lxjBEo] (VIDEO LINK)

GOOGLE - INFORMATION AND PHOTO

By the use of this color sorting machine we can save the huge amount of time in the industry. It is economical. But in 1970's the color sorting machines were truly promoted by japan sand south Korea and they were successful in commercializing and then it was introduced in china as it is a large agricultural country.

| SL.NO | NAME OF THE COMPONENT | WORKING PRINCIPLE |

|---|---|---|

| 01 | ARDUINO NANO | Arduino Nano is a small , complete, and breadboard-friendly board based on the ATmega328. It has more or less the same functionality of the Arduino Duemilanove, but in a different package. |

| 02 | servo motor | A servomotor is a rotary actuator or linear actuator that allows for precise control of angular or linear position , velocity and acceleration. It consist of a suitable motor coupled to a sensor for position feedback . |

| 03 | ICD Display | ICD Display unit which displays value of voltage , current, frequency ,temperature, pressure, flow and etc. Our display unit can be assembled from the range of 2 inch display to 12 inch size. |

They detect the colors and seperate the items based on the colors when the item's passes before them using the sensor's . The color sorting machine can be traced back to 1930. At that timed, the American 'SEM COMPANY' and the British 'SORTEX COMPANY' Developed a rice color sorting machine ,but it was not promoted because the effect of color sorting was limited on the other hand production costs were high and the factory was not having purchasing power.

- It helps in sorting of object based on three color approach. It also helps in counting of objects.

- Automated system can be built using color sensors which help in completion of work in less time .Moreover human intervention is not needed.

- Powerful and large memory color sensor ICs are available at low cost. This has driven its use in many applications.

- With the advancement of technology and memory loaded with color intensity data , color sensor controller can store and and can make color matching decisions on unlimited number of colors virtually.

- It is easy to change or modify manufacturing setups without even reprogramming the sensor device. This is beneficial in low volume manufacturing applications having frequent color variations.

YOUTUBE - [https://youtu.be/g3i51hdfLaw] (VIDEO LINK 2)

GOOGLE-INFORMATION AND PHOTO

Rapid increase in volume and type of solid and hazardous waste due to continuous economic growth, urbanization and industrialization , is becoming a burgeoning problem for national and local governments to ensure effective and sustainable management of waste. It is estimated that in 2006 the total amount of municipal solid waste generated globally reached 2.02 billion tones.

fig.1 automated waste segregator

fig.2 diagram

| SL.NO | NAME OF THE COMPONENTS | WORKING PRINCIPLE |

|---|---|---|

| 01 | BENDING ROLLERS | A roll bender is a mechanical jig having three rollers used to bend a metal bar into a circular arc ,The rollers freely rotate about three parallel axis, which are arranged with uniform horizontal spacing. |

| 02 | SPINDLE WHEEL | |

| 03 | CHAIN SPROCKETS | A chain and a sprocket drive is a type of power transmission in which a roller chain engages with two or more toothed wheels or sprockets used in engines as a drive from crankshaft to camshaft. |

| 04 | BEARINGS | A bearing is a machine element that constraints relative motion to only the desired motion, and reduces friction between a moving parts. Most bearings facilitate the desired motion by minimizing friction. Bearings are classified broadly according to the type of operation, The motions allowed or to the direction of Loads applied to the parts. |

| 05 | HOUSING | |

| 06 | SCREW | A screw is a mechanism that converts rotational motion to linear motion, and a torque to a linear force .It is one of the six classical simple machines. The most common form consists of a cylindrical shaft with helical grooves or ridges called threads around the outside. |

| 07 | MOVING ROLLER | The upper roller moves vertically at the center symmetrical position of the two lower rollers. It is obtained by the transmission of the screw nut and the worm. Rotational motion ,through the output gear of the reducer meshing with the lower roller gear, provides torque for the rolled sheet. |

The automatic waste segregation machine is equipped with various devices such as conveyor belt ,uniform distributive machine, etc. The reasonable structure and configuration can guarantee the trash sorter to achieve fully automatic operation , avoid manual operation mistakes , reduce labor intensity and improve working efficiency.

1)After the garbage truck entering the field, the garbage firstly will be unloaded on the loading platform ;the large pieces of garbage such as furniture, tree, large construction waste, is separated out by manual; then the garbage is conveyed to the plate feeder by the hopper ;there is an adjustable uniform garbage distributing machine added in the back of the plate feeder , coordinated with each other to rotary ,and the height can be adjusted , which plays a role in feeding uniformly and ensuring the normal and efficient work of the follow -up equipment.

2)After evenly distributed by the distributing machine, the municipal solid waste is conveyed to manual sorting platform by belt conveyor, where the workers will sort the large objects contained in the municipal solid waste out, including quilts, cotton clothes , truck, branches , long sticks and hazardous waste will be also selected out.

3)The waste having been sorted by manual is sent to rotating screening treatment ; according to the requirement of this process , we set the sieve plate aperture of the screening machine as 50mm; the machine can divide the MSW into parts, materials larger than 50 mm on the sieve and the materials smaller than 50mm under the sieve.

4)The waste materials that are smaller than 50mm are mainly organic matter , which go through the hanging magnetic separator to select out iron materials (ex- caps, batteries, coins) the the remaining waste is sent to compost workshop for composting.

5)The materials larger than 50mm go through the magnetic separator to select out the iron material including iron beverage cans and iron cans then the remaining materials larger than 50mm are sent to bag breaker machine for breaking up the waste in the bags and then sent to comprehensive winnowing machine can sort out three kinds of material firstly , light waste plastics; secondly ,heavy materials (bricks and stones , rubber overshoes ,tiles);third , secondary heavy material (hard plastic , textile , rubber products, wet paper product, etc)

- The special odor control system ensures that the workshop has a good environment and protects the workers health.

- The fully sealed garbage sorting production process can reduce the pollution of the garbage.

- All the final products obtained from the waste segregation machine can be processed into useful resource or disposed of without generating any pollutant.

A barcode or bar code is a method of representing data in a visual, machine-readable form. Initially, barcodes represented data by varying the widths and spacings of parallel lines. These barcodes, now commonly referred to as linear or one-dimensional (1D), can be scanned by special optical scanners, called barcode readers, of which there are several types. later, two-dimensional (2D) variants were developed, using rectangles, dots, hexagons and other patterns, called matrix codes or 2D barcodes, although they do not use bars as such. 2D barcodes can be read using purpose-built 2D optical scanners, which exist in a few different forms. 2D barcodes can also be read by a digital camera connected to a microcomputer running software that takes a photographic image of the barcode and analyzes the image to deconstruct and decode the 2D barcode. A mobile device with an inbuilt camera, such as smartphone, can function as the latter type of 2D barcode reader using specialized application software (The same sort of mobile device could also read 1D barcodes, depending on the application software).

A QR code (an initialism for Quick Response code) is a type of matrix barcode (or two-dimensional barcode)[1][2] invented in 1994 by the Japanese automotive company Denso Wave.[3][4] A barcode is a machine-readable optical label that can contain information about the item to which it is attached. In practice, QR codes often contain data for a locator, identifier, or tracker that points to a website or application. A QR code uses four standardized encoding modes (numeric, alphanumeric, byte/binary, and kanji) to store data efficiently; extensions may also be used.

The Quick Response system became popular outside the automotive industry due to its fast readability and greater storage capacity compared to standard UPC barcodes. Applications include product tracking, item identification, time tracking, document management, and general marketing.

A QR code consists of black squares arranged in a square grid on a white backgrounds, which can be read by an imaging device such as a camera, and processed using Reed–Solomon error correction until the image can be appropriately interpreted. The required data is then extracted from patterns that are present in both horizontal and vertical components of the image.

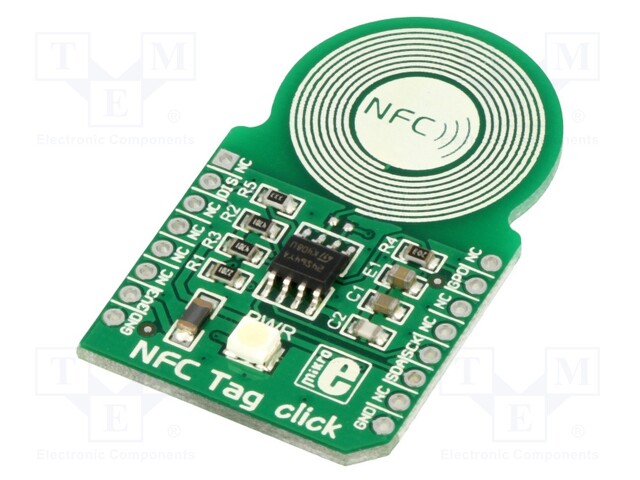

Near-field communication (NFC) is a set of communication protocols that enables communication between two electronic devices over a distance of 4 cm (11⁄2 in) or less.NFC offers a low-speed connection through a simple setup that can be used to bootstrap more-capable wireless connections.

NFC devices can act as electronic identity documents and keycards.They are used in contactless payment systems and allow mobile payment replacing or supplementing systems such as credit cards and electronic ticket smart cards. These are sometimes called NFC/CTLS or CTLS NFC, with contactless abbreviated as CTLS. NFC can be used to share small files such as contacts and for bootstrapping fast connections to share larger media such as photos, videos, and other files.

A barcode reader (or barcode scanner) is an electronic device that can read and output printed barcodes to a computer. Like a flatbed scanner, it consists of a light source, a lens and a light sensor translating optical impulses into electrical ones. Additionally, nearly all barcode readers contain decoder circuitry analyzing the barcode's image data provided by the sensor and sending the barcode's content to the scanner's output port

It is an electronic device that can read the printed barcodes. It consists of a light source, a lens and a light sensor translating optical impulses into electrical pulses. In this paper, we are using Barcode scanner to read the printed PIN codes as barcodes which is shown in

A QR code scanner is an optical scanning device that's able to read QR codes. Most tablets and smartphones have BUILD-in QR code scanners in their cameras. That means you can likely POINT your camera at a QR code and be able to scan and read it.

A QR reader can identify a standard QR code BASED on the three large squares outside the QR code. Once it has identified these three shapes, it knows that everything contained inside the square is a QR code. The QR READER then analyzes the QR code by breaking the whole thing down to a grid.

YOUTUBE- [https://youtu.be/EnIkQnR3DDw] (VIDEO LINK 3)

GOOGLE- INFORMATION AND PHOTOS