-

Notifications

You must be signed in to change notification settings - Fork 0

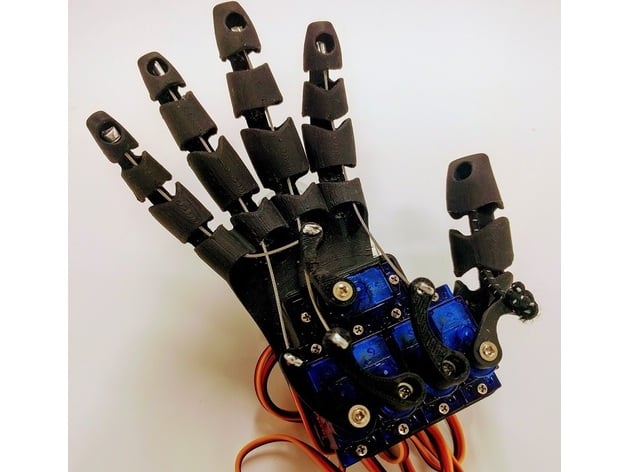

The Hand

Our project is a robotic hand controlled by the Leap sensor and the Emotive Epoc+ sensor.

It is made of ABS plastic and Flexy:

- The first one is harder and stronger than the second one, and it smells bad.

- The second one is very flexible and resistant.

The mechanism is very simple: we have printed each finger bone separately (distal, intermedial, proximal and metacarpal) and then we have joined them with seams/joints.

For the movement (more info in this link) we use 5 Servo engines tied to the tips of each fingers with wires and connected to an Arduino programmable board, that wil pull and release the fingers based on data received.

We needed a reliable model to start testing the first versions of code while we were waiting for 3d printed one, so we thought we'd build it in LEGO technic bricks.

As you can see we built a left hand.

We connected the "fingers" to the servomotors through cotton threads.

Each finger is also connected to an elastic to make it return to an open position every time.

Servomotors are on the second floor, in a small housing to hold them still.

In the back we have installed a breadboard for the electric management of servomotors.

The breadboard is powered and connected to a Arduino board.

After some research we found an optimal prototype for our project, we printed it but the quality was not high and the material was not flexible enough.

So we aborted that project and we destry that, to test the resistance of the PLA.😁

Then we found another hand. Being the hand assemblable, we decide to try to print it in 3D only the thumb, with the appropriate joints and avoid wasting other material.

So we kept printing all the other fingers (ABS) and the joints (PLA).

We had to finish and polish the various parts of the hand and this is the result:.jpg?raw=true)

Then we tried to connect the first finger to the engine of Arduino and it worked properly.

Finding the PLA very unconfortable to use for joints, we decided to use Filaflex: a very flexible filament that is perfect for our needs.

But... when we inserted the filament into the extruder it rolled around it and it couldn't be removed; so we contacted PRUSA support and they advised us to disassemble the extruder; we looked for a guide and finally we were able to extract the filament and load it properly without problems.

Finally we joined all the pieces of the hand and created, momentarily, a support in Lego and this is the result!:

The last part of our project involved the construction of a wooden forearm that contained the servomotors, the remaining electrical component and allowed the movement of the wrist.