Beechat Juice was envisioned with the same concept as the Beechat Network, applied to energy instead of communications. In essence, we want to provide the world with access to an Open Source solar energy generation machine, that is scalable and reproducible by anyone with access to simple tools, or even large factories.

If there were to be some sort of global or regional supply chain collapse, a low-tech Open Source solution like Beechat Juice would be vital to provide people with an energy solution that is local and does not require a complex trade network. For the first version, we decided to focus on CSP, as materials are cheap, abundant, and easily recyclable. This project aims to bring, not only Open Source CSP technology, but also VAWT, and Geothermal, Hydro, and others in the future.

- Powering IoT devices

- Providing a reliable small-scale source of power in remote locations

PV technology has come a long way in the past decades, with massive improvements in efficiency. However, that efficiency comes at a cost, environmental, societal, and economic.

-

Environmental: (1) Energy intensive: For each 1 m2 of PV solar panel, 350 kilograms of Coal (or equivalent energy source) need to be used to create it. (2) The production of the solar-grade silicon for one square meter of panel area requires 3.5 kg of concentrated hydrochloric acid. (3) Traditional silicon solar cells are considered safe, but the manufacturing of those cells does produce silicon tetrachloride – a highly toxic byproduct harmful to plants and animals.

-

Economics: PV manufacturing is only profitable at a large scale, preventing small manufacturers from creating solar panels at a profitable level.

-

Societal: This is related to the environmental factors above, but the amount of rare earth metals and semiconductor technology needed, in addition to large scale factories (typically in countries with low worker rights and high level of abuse), means the current manufacture of PV panels comes at a high societal cost.

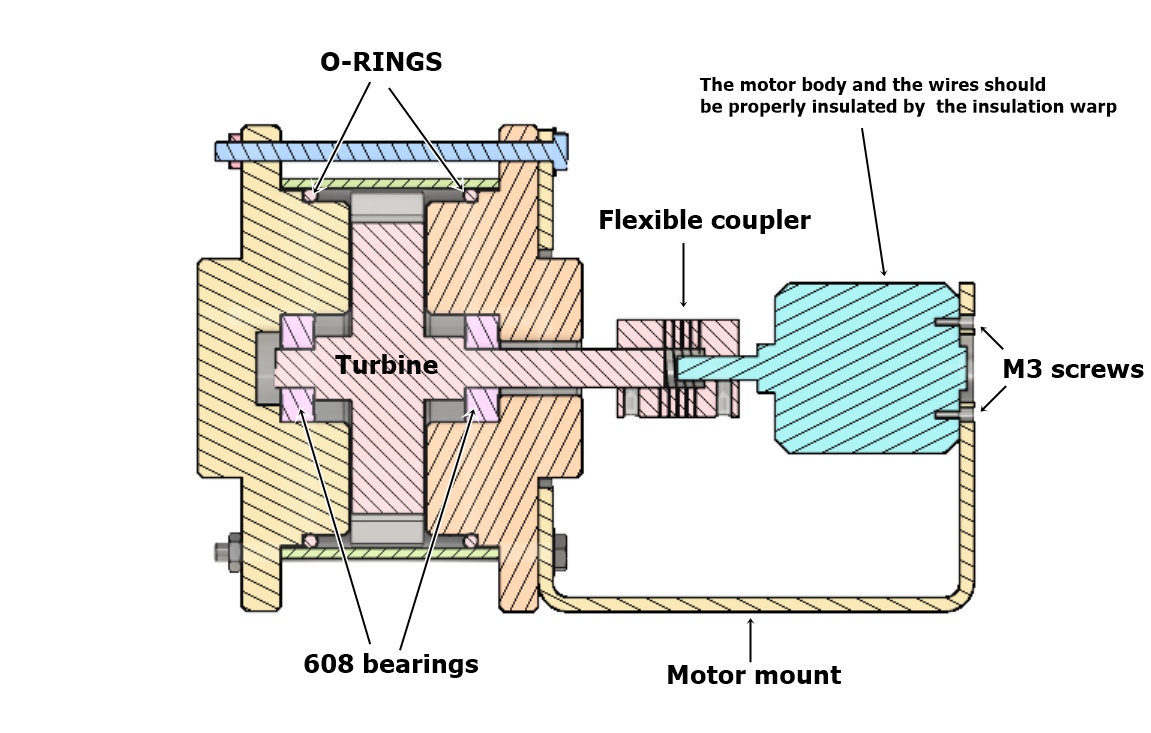

- Turbine assembly model:

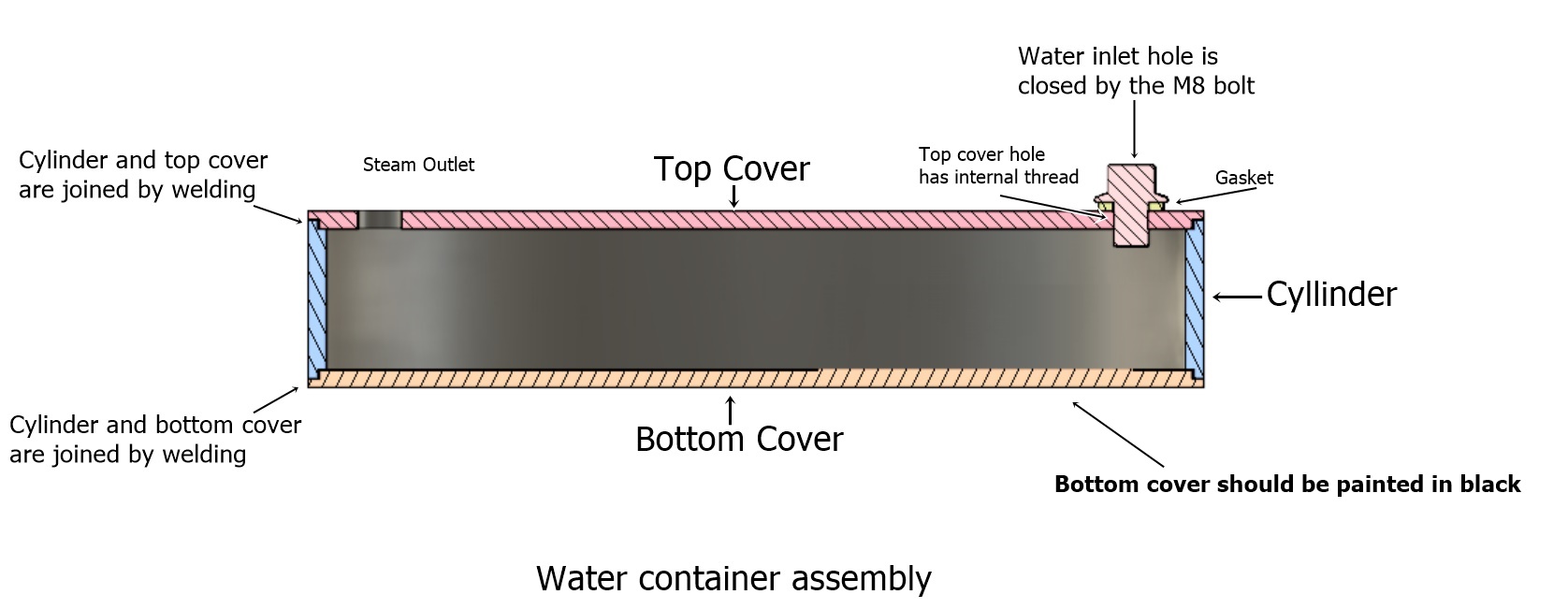

- Water container assembly model:

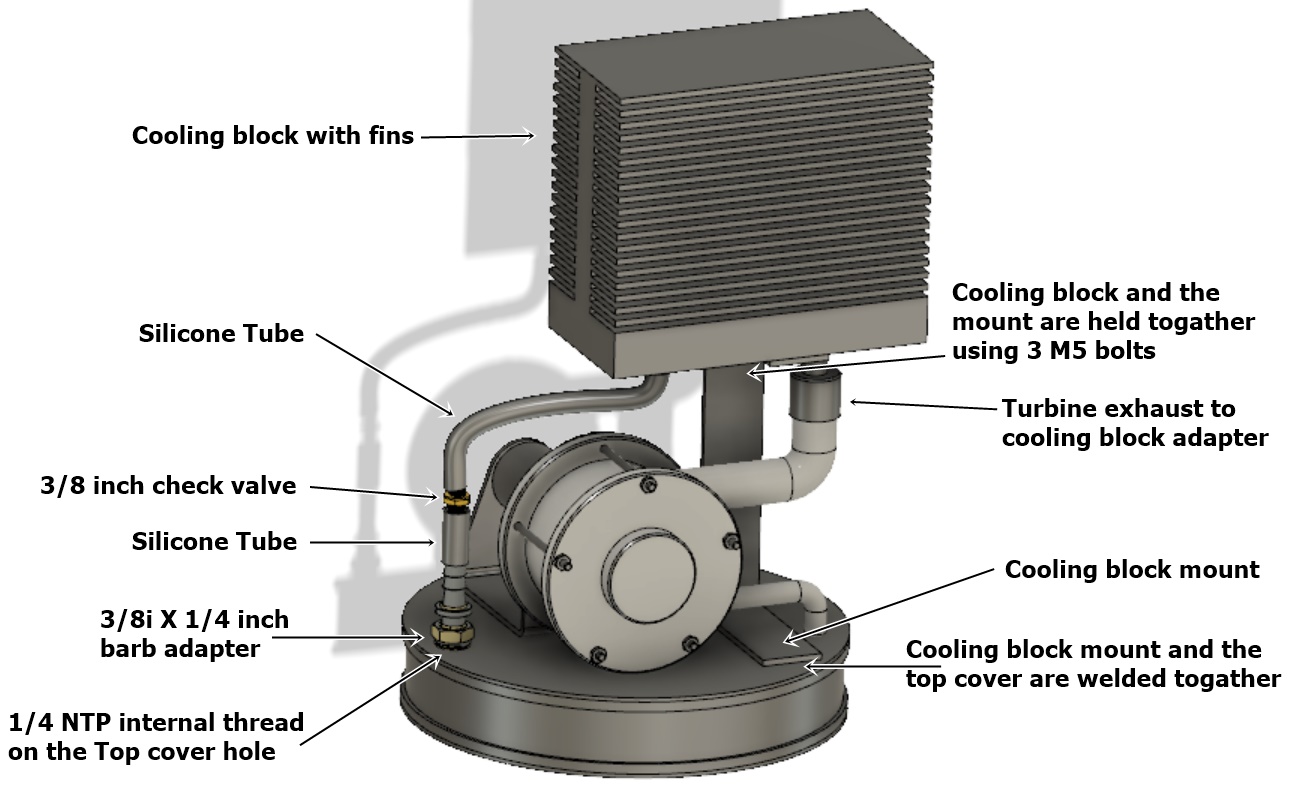

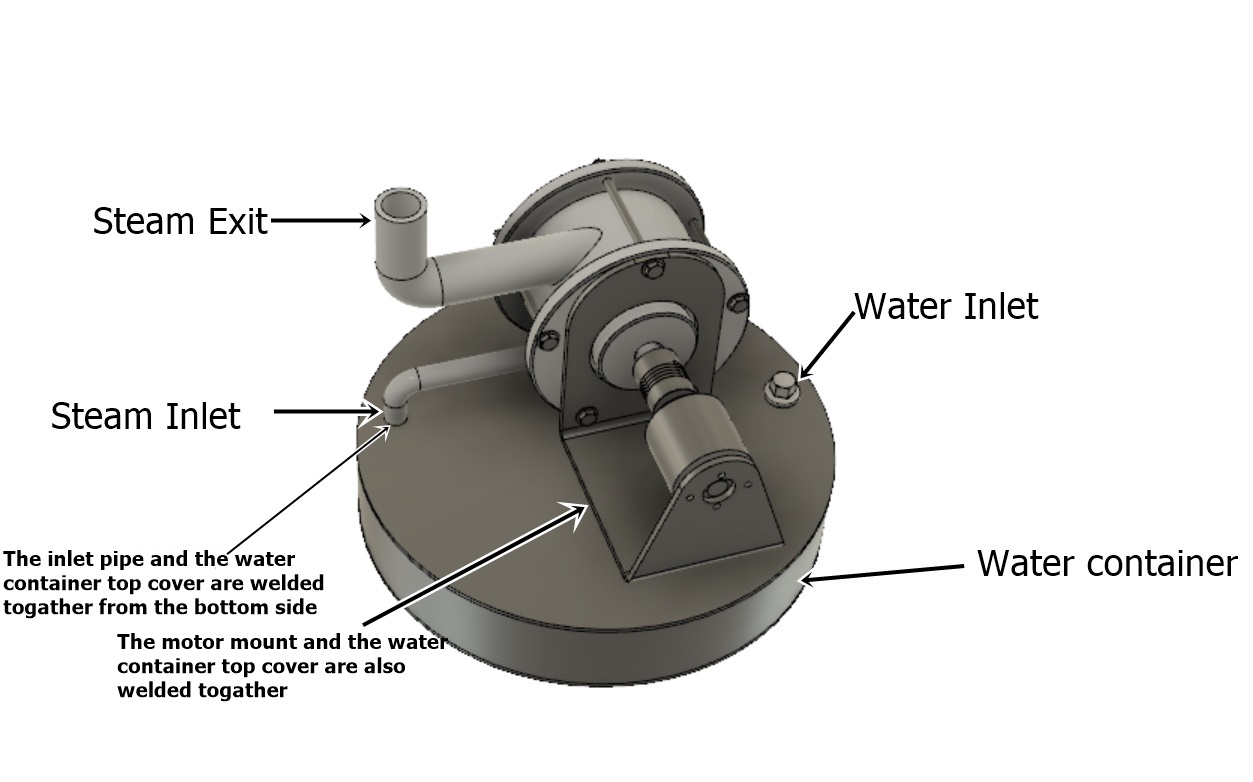

- Full assembly model:

- BOM & Parts sourcing created.

- Passive cooling system to prevent liquid loss

- Prototype construction & test

| Time | Milestone |

|---|---|

| Q1 '21 | Design of assembly V1 incl. passive condensation |

| Q2 '22 | Test of assembly V1 |

| Q3 '22 | Tracking tripod design |

| Q4 '22 | Design iteration & test of V2 |

| Q1 '23 | Production run #1 |

| Future | Further testing, R&D |

This system (Software & Hardware) is licensed under the MIT License.