Alrighty, so you got your tg4x stuff, but don’t know how to put it together. I’ve finally gotten around to making this build guide, so now you’re covered. Inside your box (depending on what you ordered), you should have 2 packages.

One bag is the plates, and the pcb. The other is your assembly kit, which contains all of the other pieces and components you need.

One bag is the plates, and the pcb. The other is your assembly kit, which contains all of the other pieces and components you need.

Inside your assembly kit, you’ll find 50x diodes, a reset switch, a pro micro, 8x ws2812b rgb leds, ~28x screws, 5x 5mm male/female standoffs, 13x 11mm female/female standoffs, and some little rubber feet.

Inside your assembly kit, you’ll find 50x diodes, a reset switch, a pro micro, 8x ws2812b rgb leds, ~28x screws, 5x 5mm male/female standoffs, 13x 11mm female/female standoffs, and some little rubber feet.

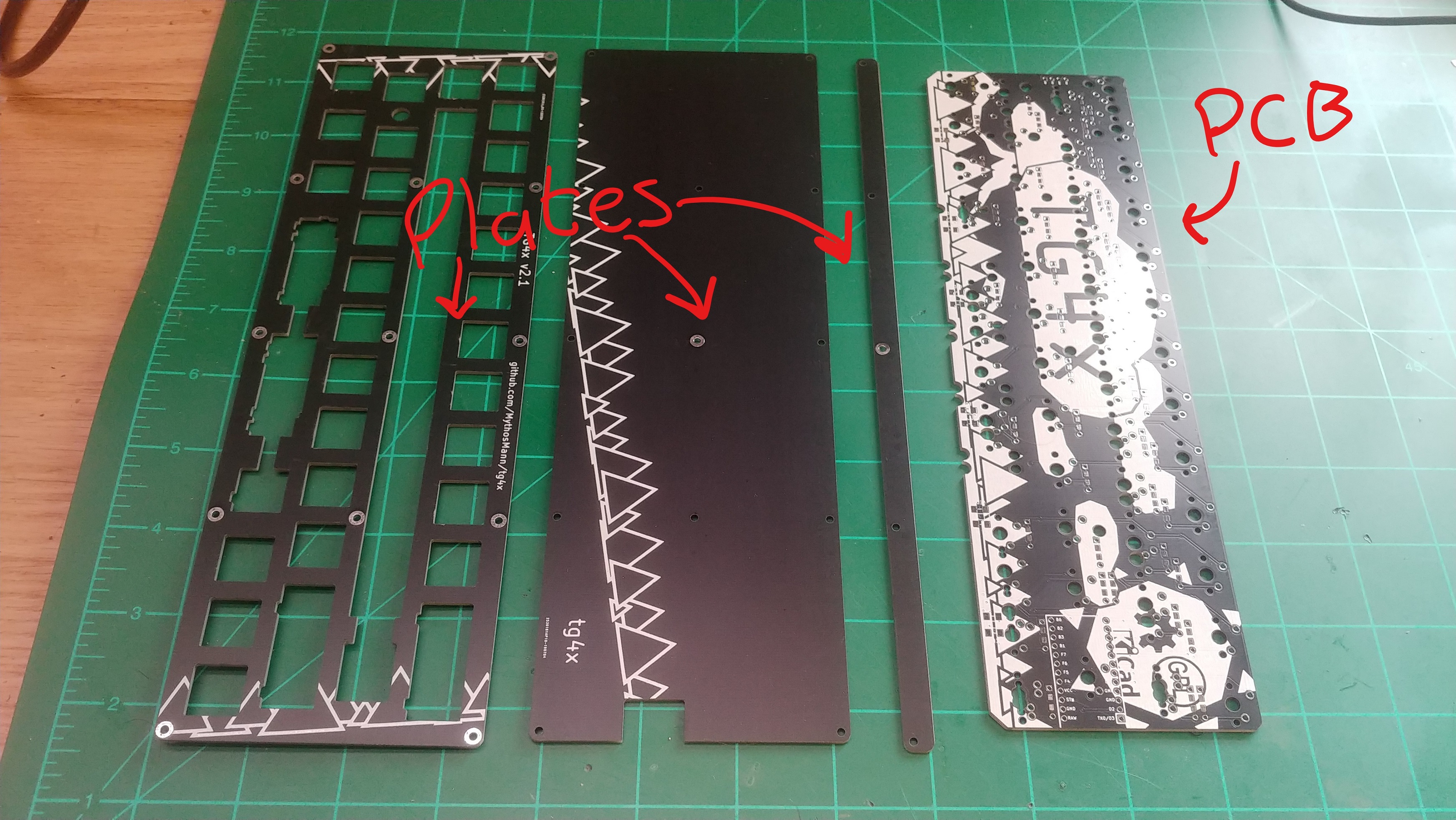

In the other package, you’ll get a top plate, bottom plate, and a skinny little plate that you can use as a foot (to add a ~5 typing angle). You’ll also get the pcb, where the magic happens.

In the other package, you’ll get a top plate, bottom plate, and a skinny little plate that you can use as a foot (to add a ~5 typing angle). You’ll also get the pcb, where the magic happens.

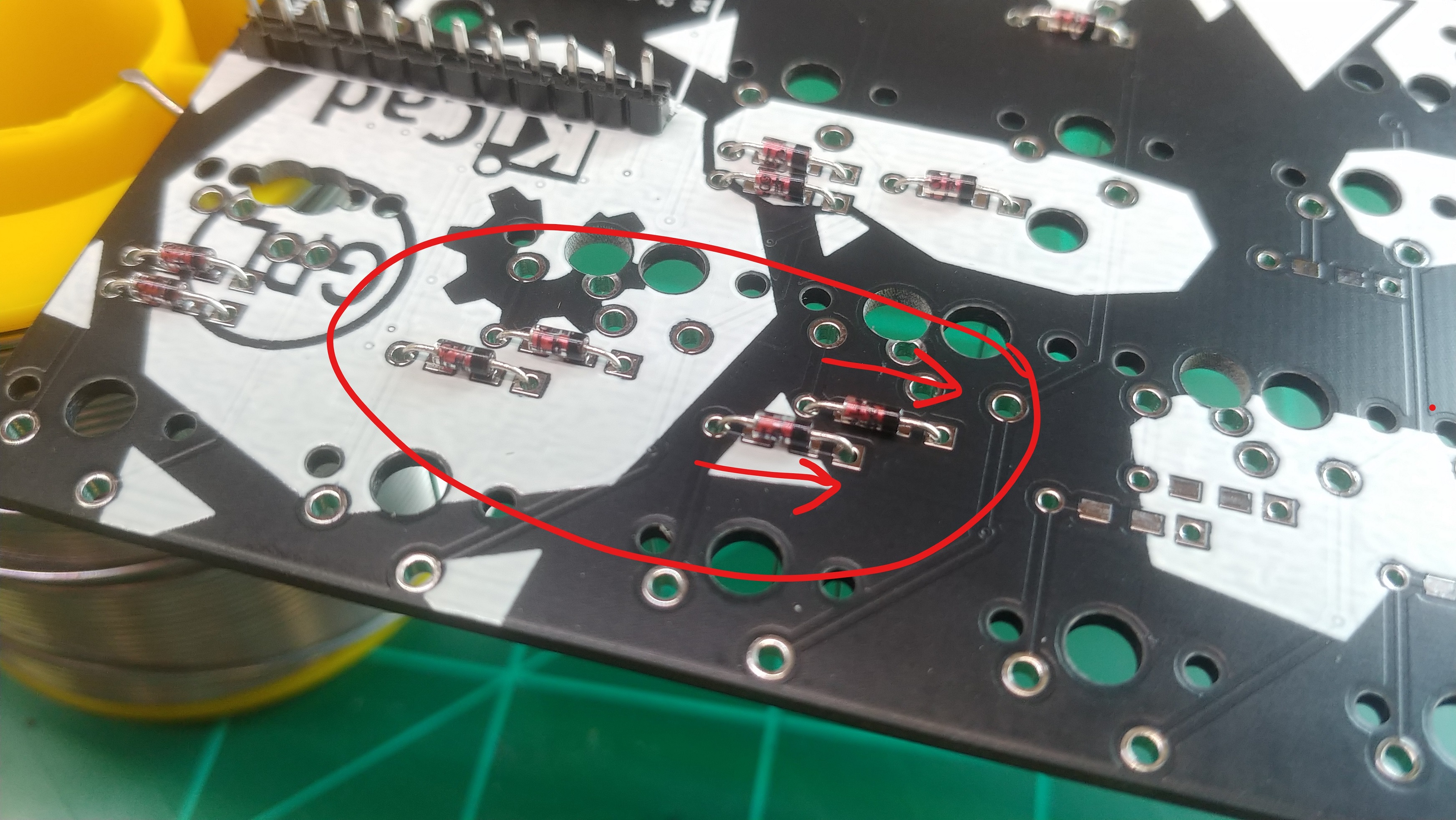

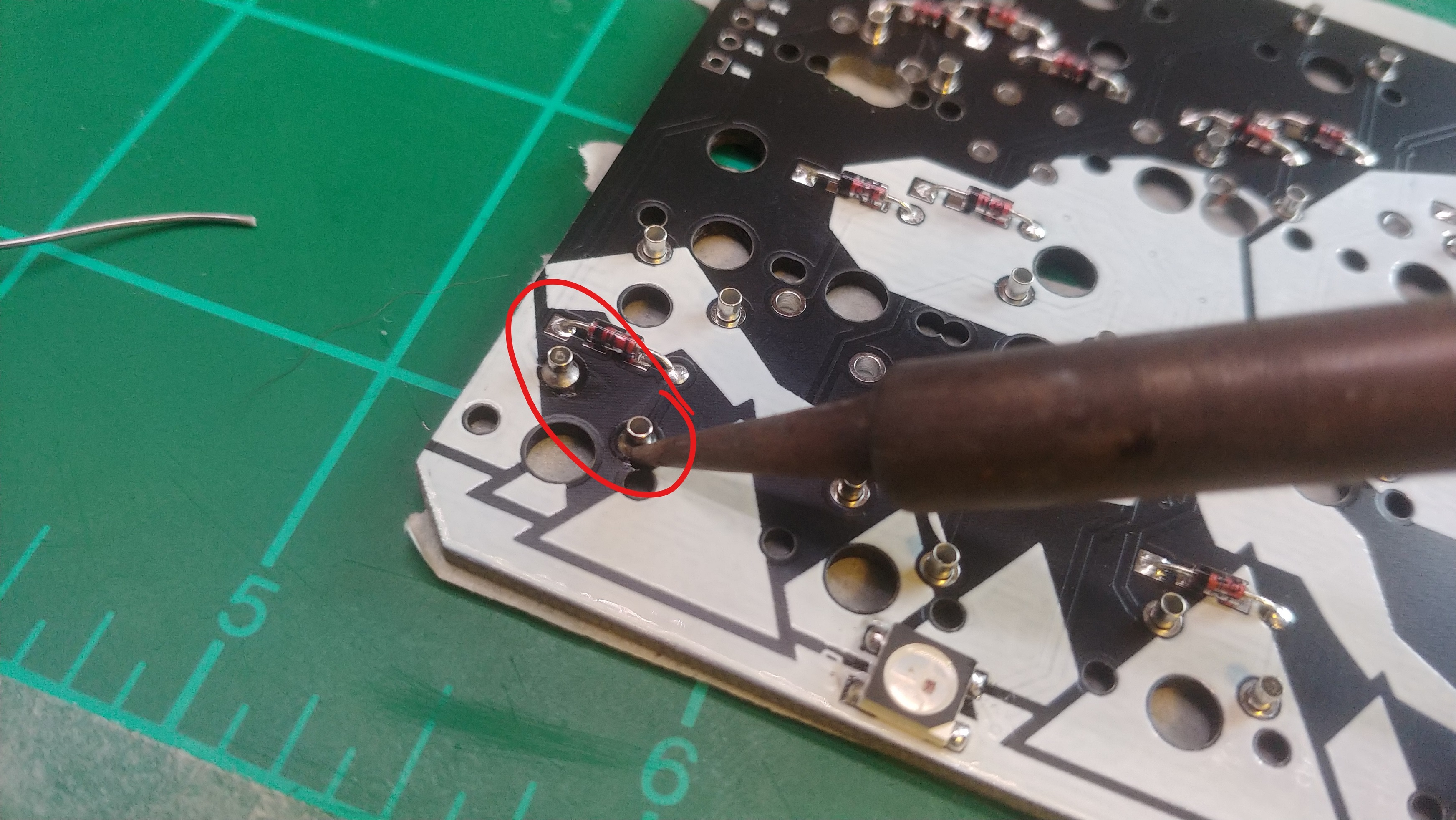

First thing you’ll want to do is bend all your diodes. An easy way to do it consistently is to use your plates and pcb, put the diodes on top, and push all the legs down. Then you’ve got to pull the paper off all the leads. Next, you’re gonna put diodes in all of the diode holes. It doesn’t matter if you put them on the top or bottom of the pcb, but make sure that they are oriented correctly. You want the end with the black strip to go into the square holes.

First thing you’ll want to do is bend all your diodes. An easy way to do it consistently is to use your plates and pcb, put the diodes on top, and push all the legs down. Then you’ve got to pull the paper off all the leads. Next, you’re gonna put diodes in all of the diode holes. It doesn’t matter if you put them on the top or bottom of the pcb, but make sure that they are oriented correctly. You want the end with the black strip to go into the square holes.

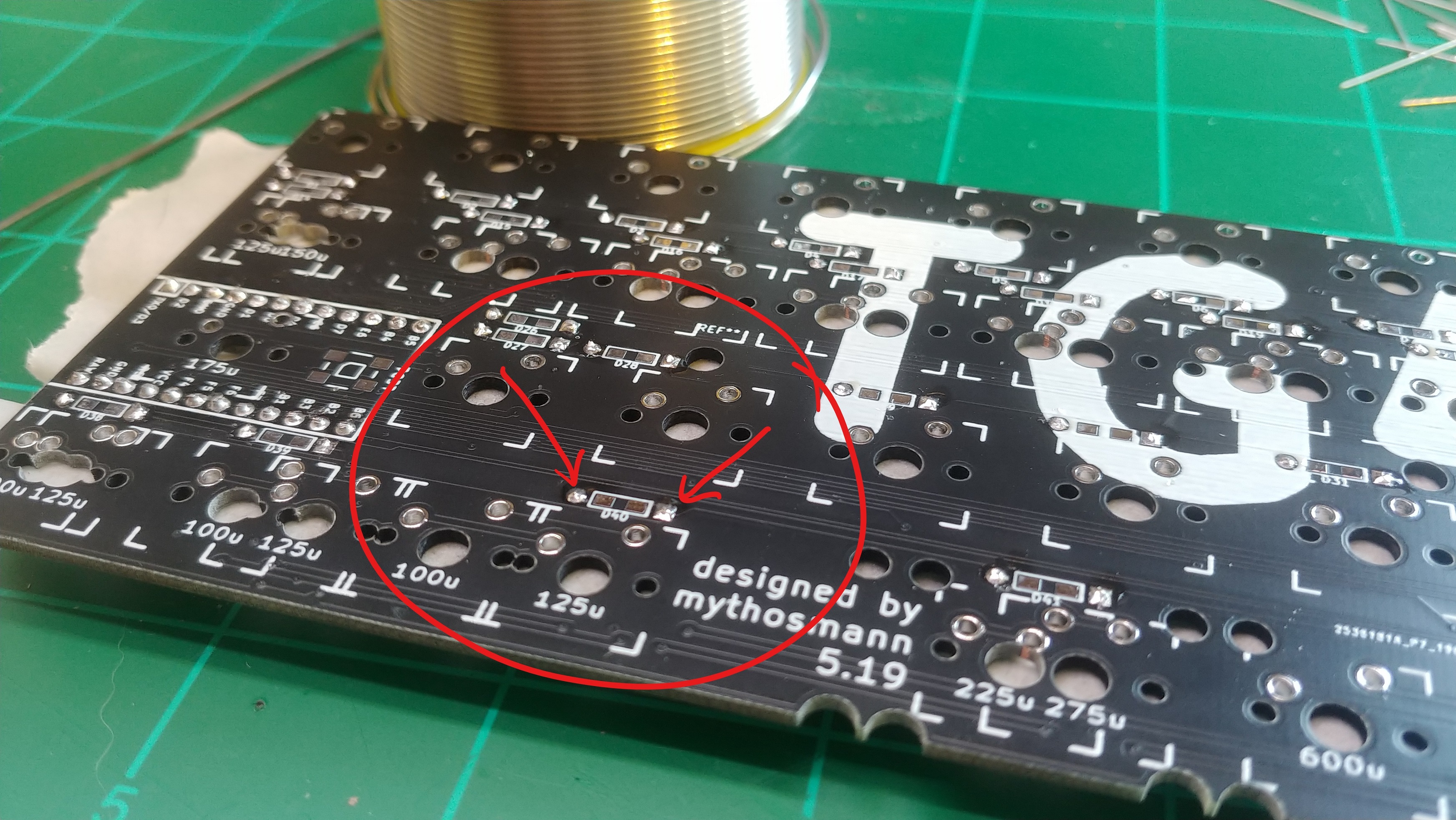

The easiest way to install the diodes is to place them all in, then use masking tape to hold them in place. Now you can flip the whole thing over, clip the legs off, and solder them all in. I find it’s easier and looks cleaner if you clip the legs before soldering, but you could also solder first.

The easiest way to install the diodes is to place them all in, then use masking tape to hold them in place. Now you can flip the whole thing over, clip the legs off, and solder them all in. I find it’s easier and looks cleaner if you clip the legs before soldering, but you could also solder first.

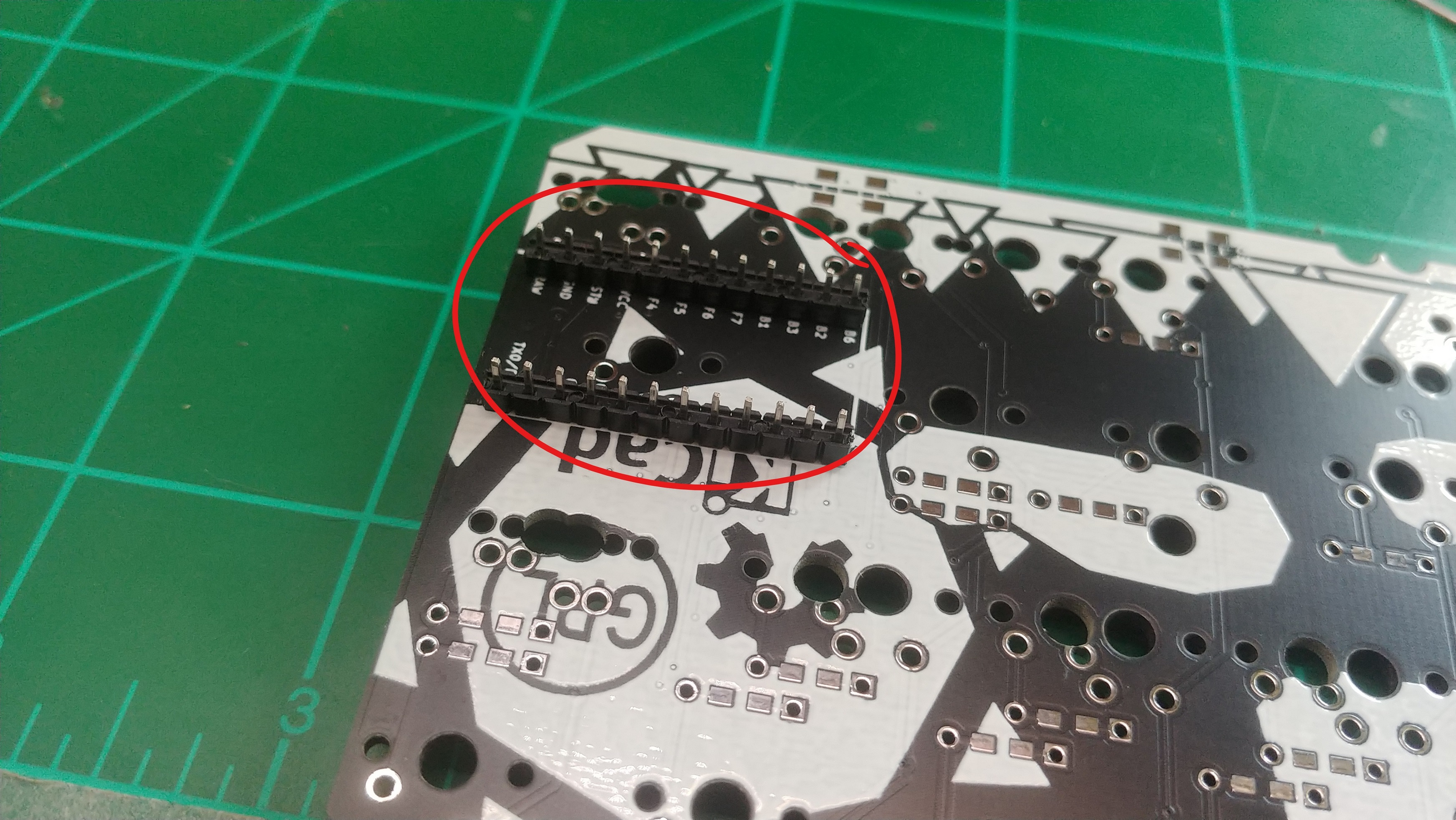

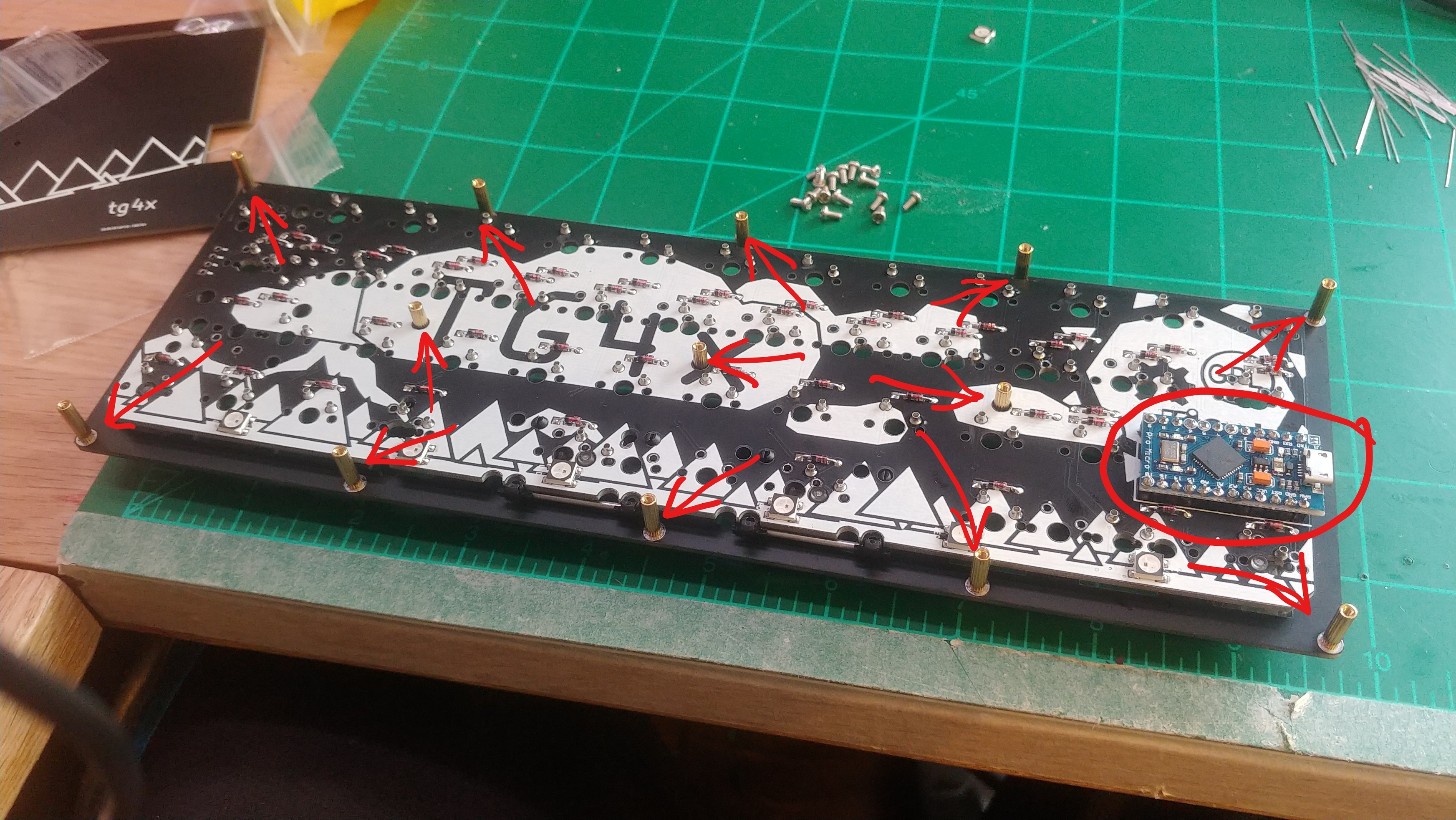

Next, you want to solder in the headers for the pro micro. You want them on the bottom of the pcb, which is the side with the big fancy graphic. Don’t solder the pro micro on yet! If you do, it’s gonna be really hard to solder the switches later. I’d put the short end of the headers away from the pcb, with the long legs going through. Then clip them flush with pcb.

Next, you want to solder in the headers for the pro micro. You want them on the bottom of the pcb, which is the side with the big fancy graphic. Don’t solder the pro micro on yet! If you do, it’s gonna be really hard to solder the switches later. I’d put the short end of the headers away from the pcb, with the long legs going through. Then clip them flush with pcb.

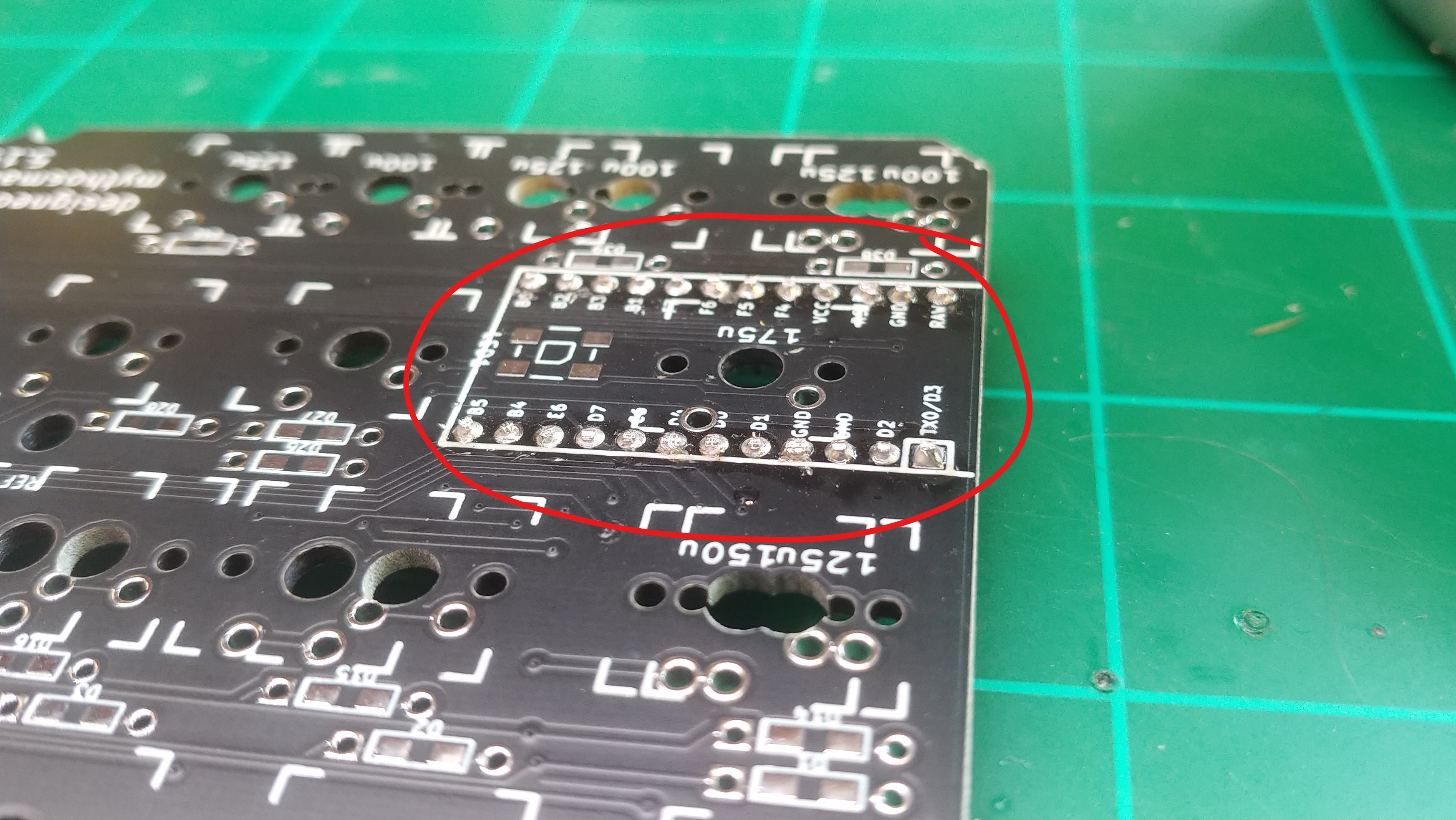

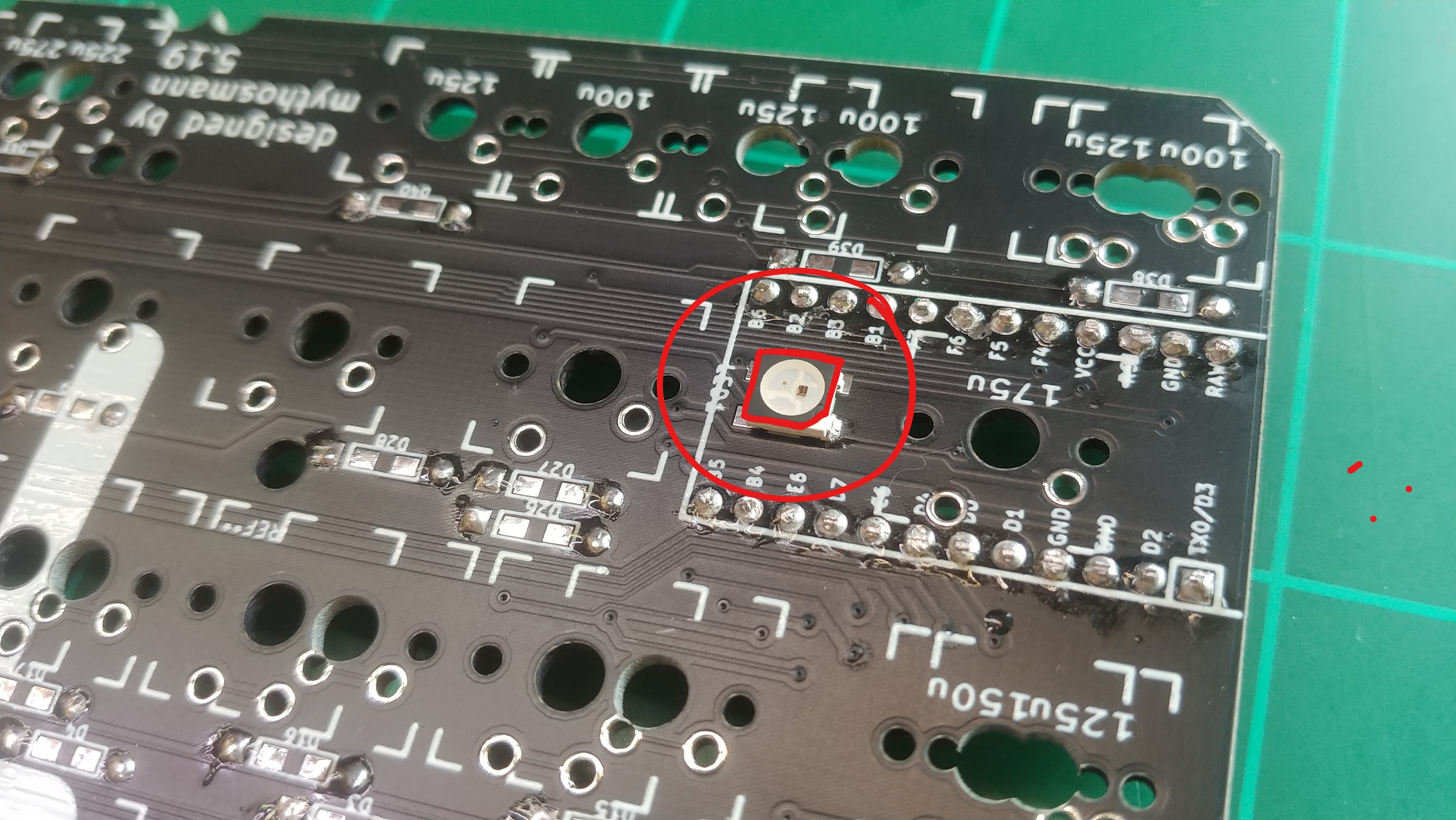

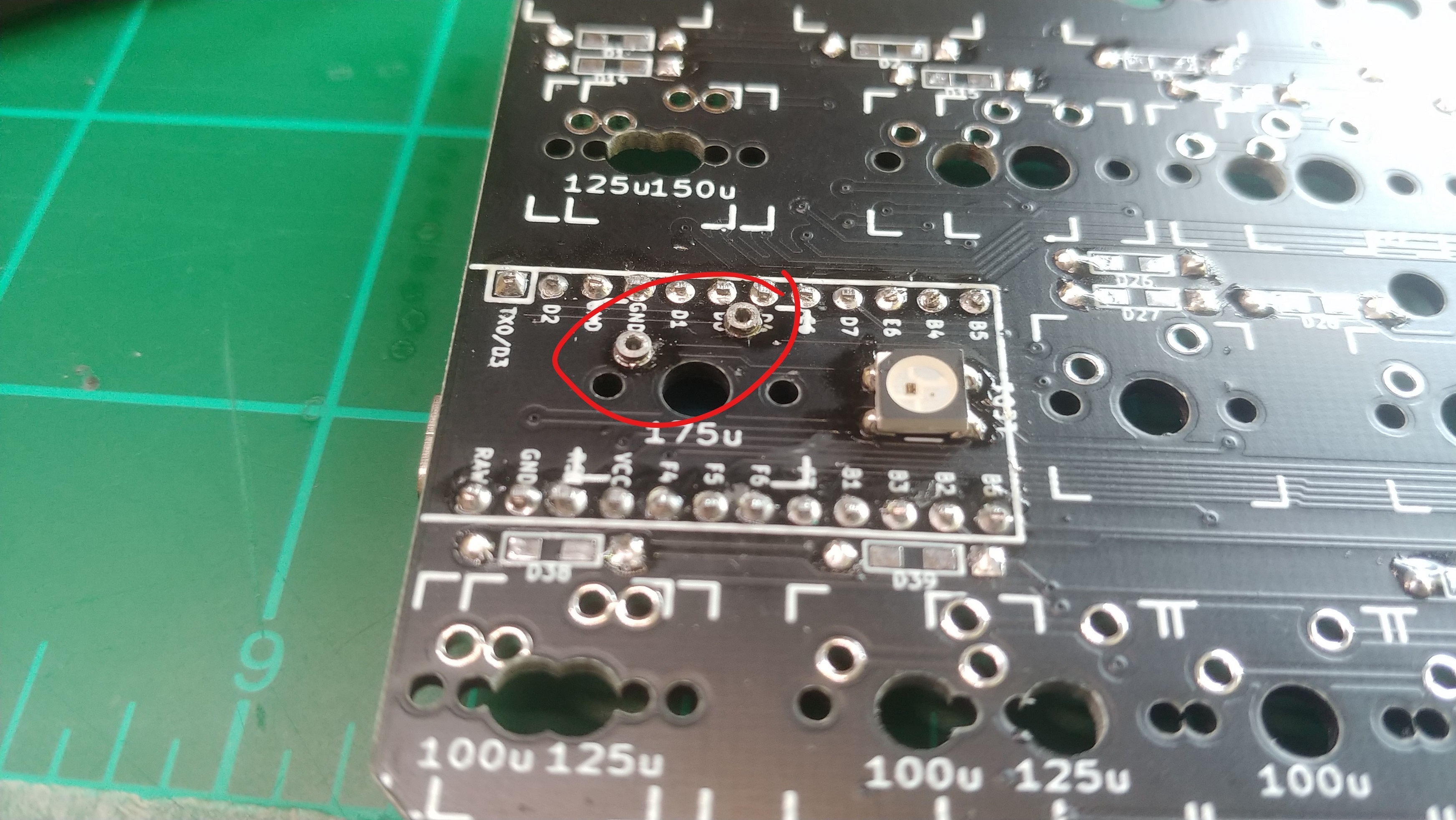

Next, solder on the leds. There’s one on the top of the pcb, and six on the bottom. For the one on top, you want to make sure that the white corner is facing the left side of the pcb. The leds on the bottom of the pcb all face down to the right, except for the one on the far right, which faces the other way.

Next, solder on the leds. There’s one on the top of the pcb, and six on the bottom. For the one on top, you want to make sure that the white corner is facing the left side of the pcb. The leds on the bottom of the pcb all face down to the right, except for the one on the far right, which faces the other way.

If you have mill-max sockets, you’ll want to solder them in now. I solder them just like diodes, so I’ll put them all in, tape over them, then solder them from the underside.

If you don’t have the sockets, skip over this step.

If you have mill-max sockets, you’ll want to solder them in now. I solder them just like diodes, so I’ll put them all in, tape over them, then solder them from the underside.

If you don’t have the sockets, skip over this step.

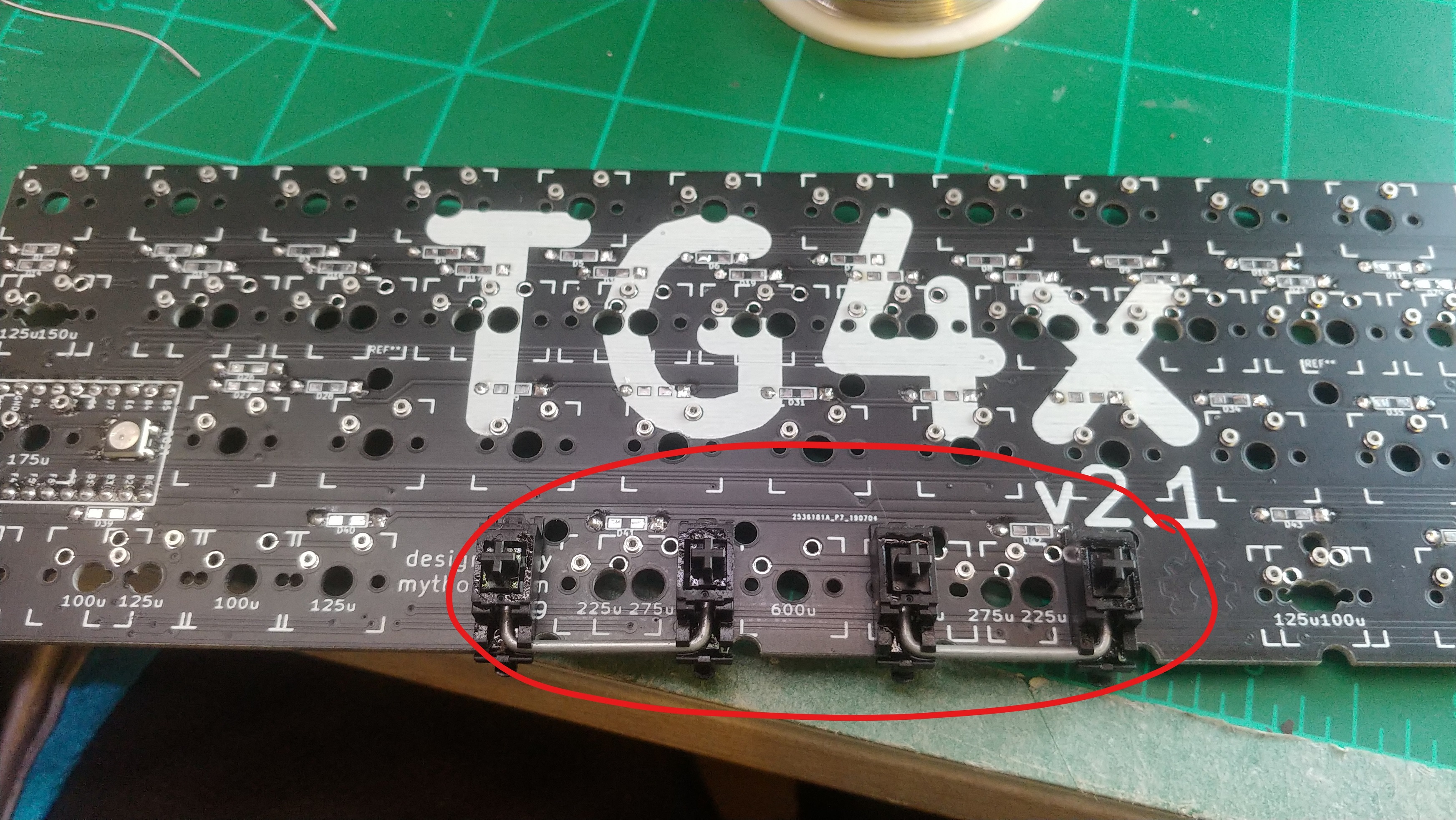

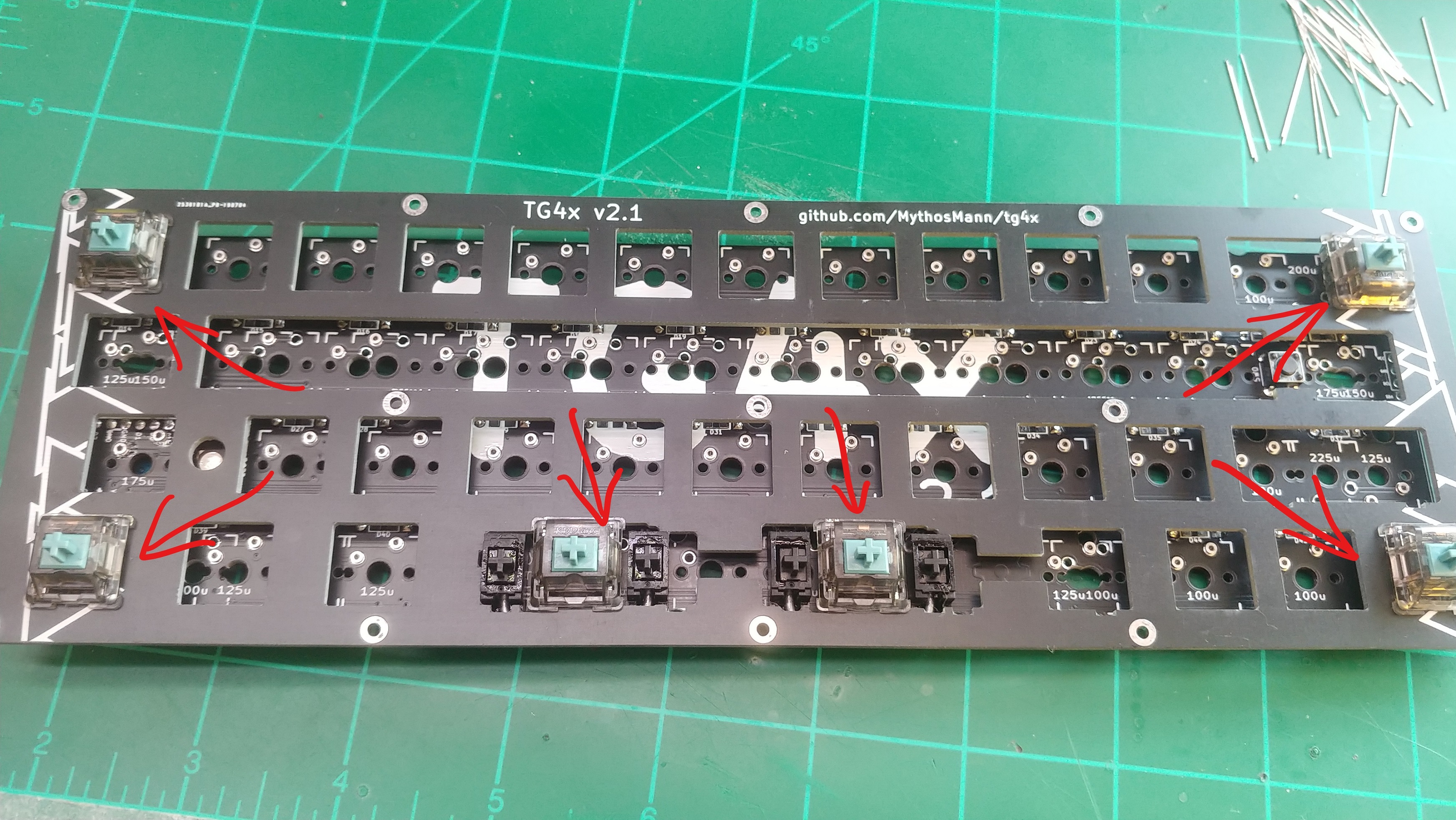

Make sure you put the stabilizers in before you start to add the switches. Put switches in each of the corners of the top plate, then fit it into the pcb. I also like to put switches where the stabs are. Solder those switches into the pcb. Now it’ll be easier to fit the rest of the switches in, and solder them. Of course, if you’re using mill-max sockets, there’s no need to solder the switches.

Make sure you put the stabilizers in before you start to add the switches. Put switches in each of the corners of the top plate, then fit it into the pcb. I also like to put switches where the stabs are. Solder those switches into the pcb. Now it’ll be easier to fit the rest of the switches in, and solder them. Of course, if you’re using mill-max sockets, there’s no need to solder the switches.

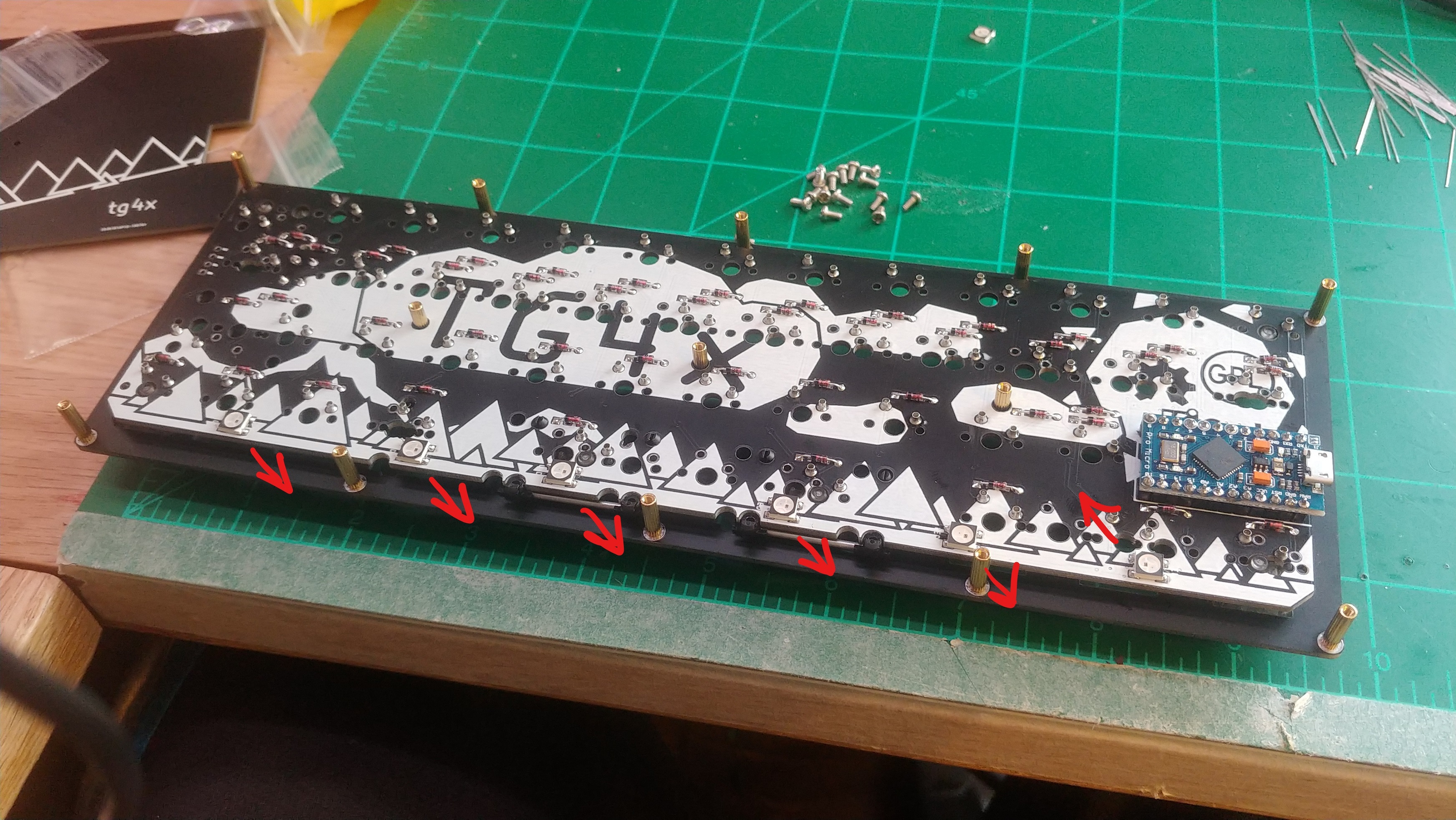

After you’ve got all the switches installed, screw in all of the standoffs to the top plate. There are 13 in total. Put the bottom plate on, and screw it down.

After you’ve got all the switches installed, screw in all of the standoffs to the top plate. There are 13 in total. Put the bottom plate on, and screw it down.

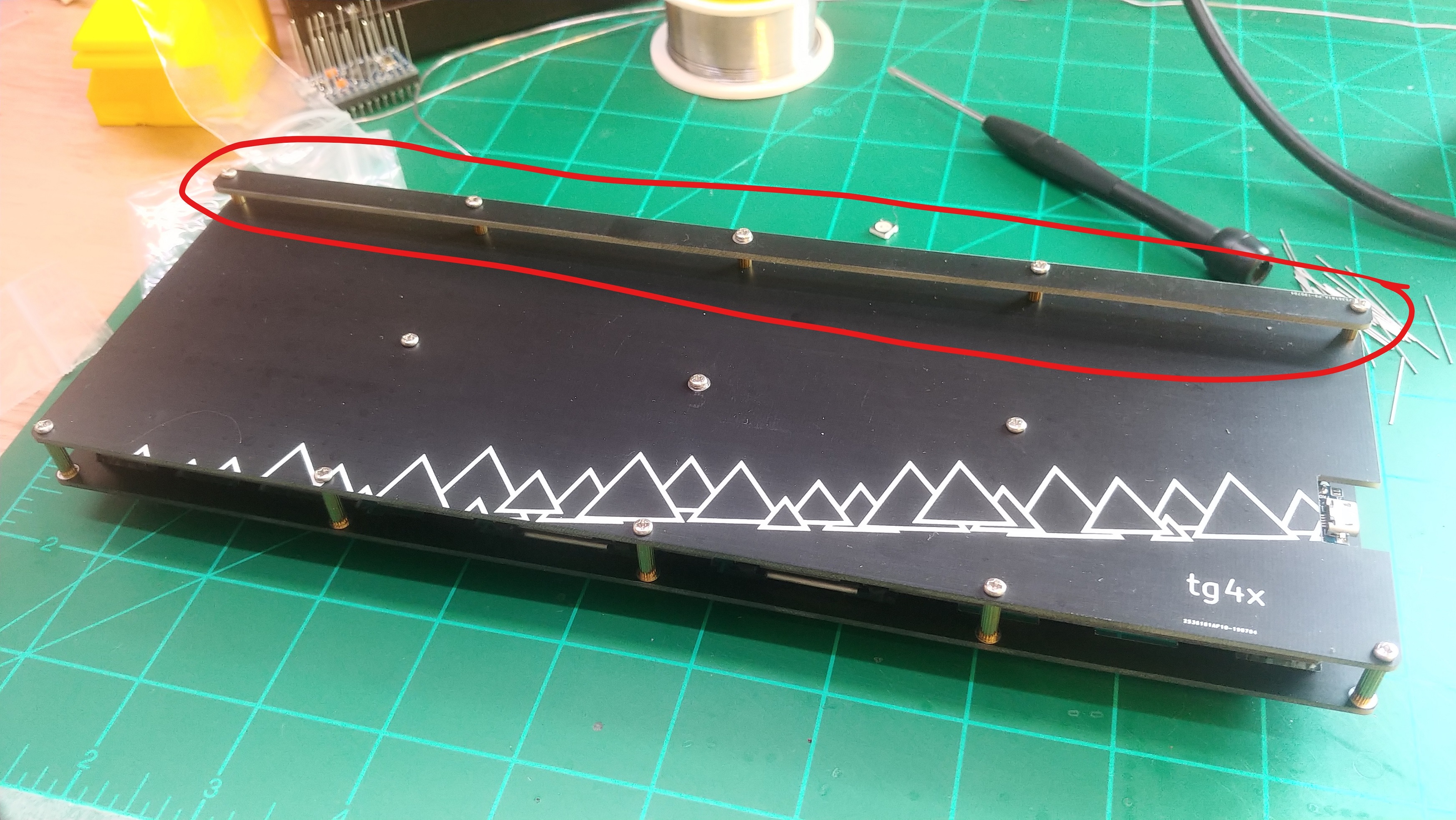

If you want a bit of angle, use the 5mm standoffs in place of the screws on the top row. Then, put the small plate on, and screw it in.

If you want a bit of angle, use the 5mm standoffs in place of the screws on the top row. Then, put the small plate on, and screw it in.

Now all you’ve got to do is stick on some rubber feet, and find your keycaps.

Now all you’ve got to do is stick on some rubber feet, and find your keycaps.