Please ensure that if you are planning to deliver these to others that you sterilise them, always assume you are infected and take every precaution.

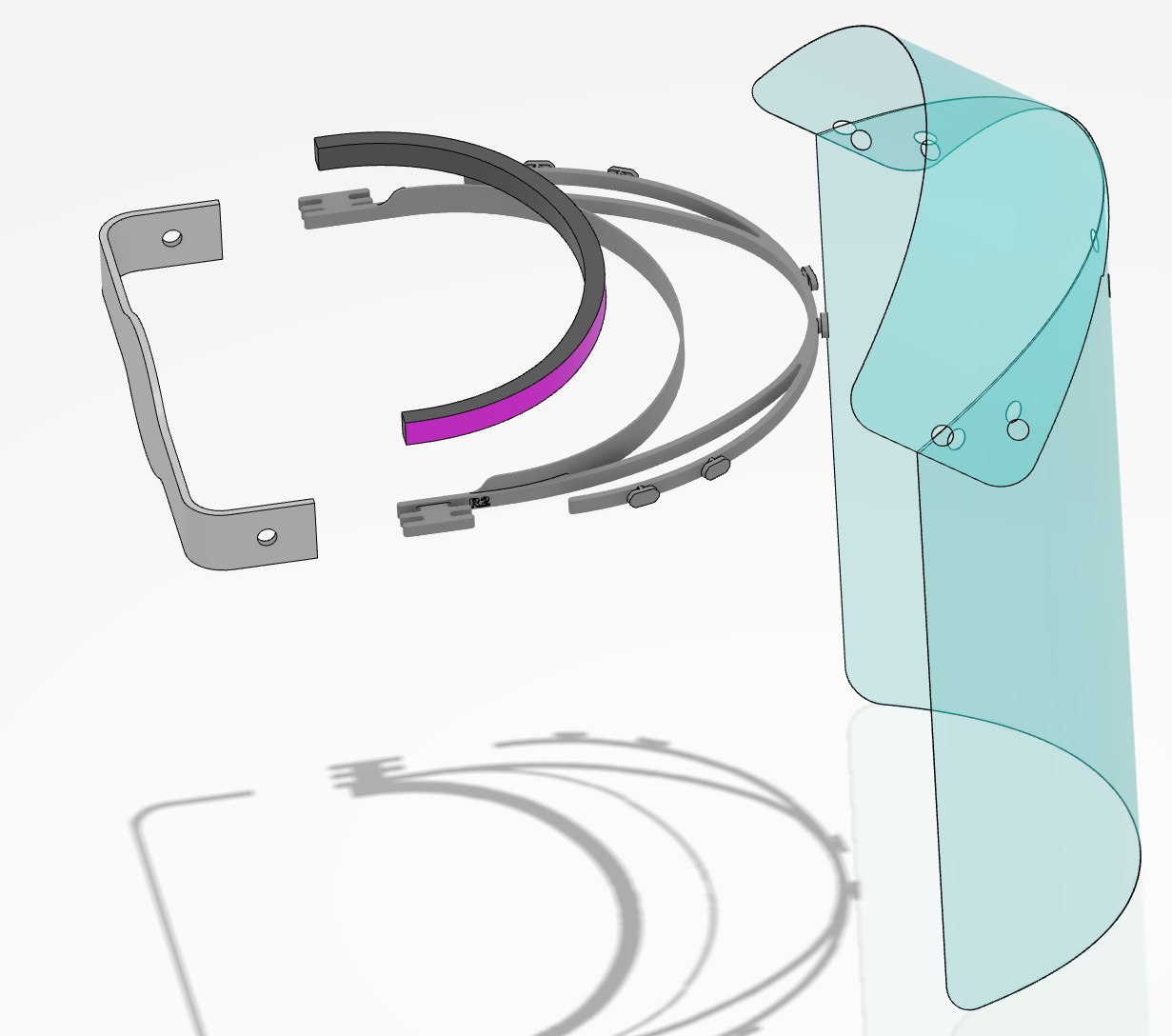

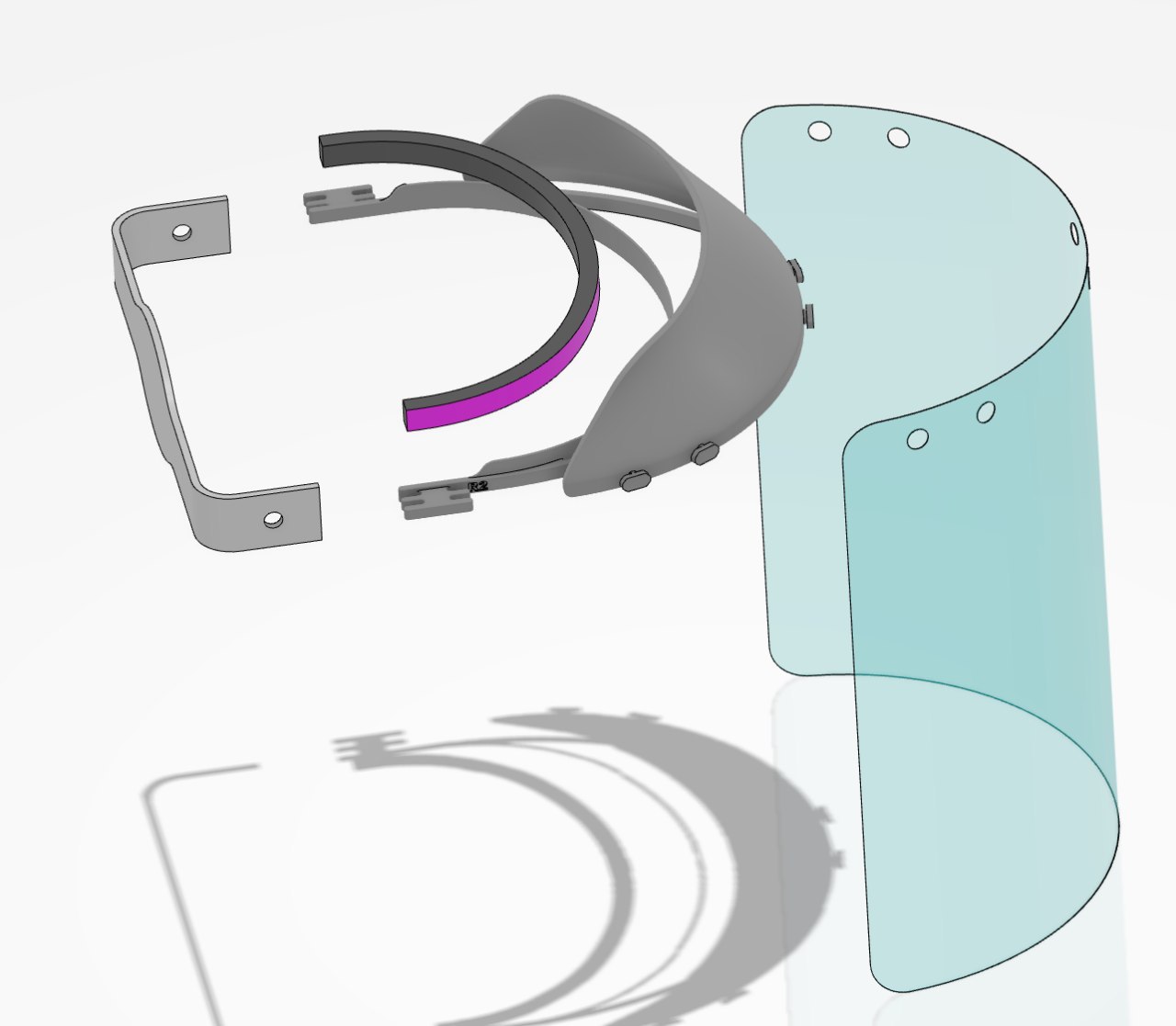

Face shield design to aid first line responders during the COVID19 Epidemic.

This design was created by members of the Washington Sate 3D Face Shield Hub.

If you are a medical professional and are in need of shields, please head to our website faceshieldhub.org

This is an update of "DtM-v3.1 Face Shield PPE, 3D printable headband NO LOGO", item 3DPX-013359.

The PNWS is available for purchase at cost on amazon at the following link. PLEASE MAKE SURE TO REMOVE THE PROTECTIVE FILM ON THE SHIELD BEFORE USE. https://www.amazon.com/dp/B08D7H37QX

- Reduced mass and print time

- Improvements to shield retention while reducing stress applied to the shield itself.

- Thinned forehead section to reduce pressure on the forehead

- Mount peg spacing changed for equivalency to "Swedish" headband

- Added brimless variant to further reduce print time and mass

- Added engineering definition for face shield and headband

- Added cloth tie clips as an option

- Added option of foam headband

- Increased spacing to improve wearability with glasses and N95 mask underneath.

- Reduced weight solves for headaches from all-day wear of previous model

- Optimised build and assembly to standard materials that can be readily purchased (e.g., US letter-sized transparency)

Due to a domestic supply chain gap for transparent face shields, this remixed 3D printed design immediately provides personal protective equipment (PPE) to healthcare workers responding to COVID-19, and incorporates clinical feedback and clinical reviews from other similar designs being used across hospitals across the nation. Face shield characteristics:

- limits aerosol and splatter exposure directly to the anterior head, specifically to the face and from above the head, while providing top ventilation to limit fogging and condensation

- reduces aerosol and splatter exposure on N95 and other face masks; this follows current recommendations to use full face shields to protect limited supply N95 masks

- re-usable for a single user (can survive multiple daily washes; transparent visor can be replaced from readily sourced materials when worn out)

easy to fabricate within a few days of design approval (i.e., no complex supply chains or production bottlenecks) comfortable to wear and easy to don and doff (as it will be taken on and off dozens of times in a 12-24 hour shift) provides protection to broader area of face compared to standard safety goggles or glasses

License - Apache 2.

Once you download the fabrication package you will be see there is an assembly drawing and a BOM, please open these first to help decide which parts you would like to print.

Download the PNWS Full Release Package

NIH Link - https://3dprint.nih.gov/discover/3dpx-013883

Download the PNWS Short Release Package

NIH Link - https://3dprint.nih.gov/discover/3dpx-013884

Yes! Please look at the Sliced Files folder. If you would like to contribute to these please reach out and we can get them added.

If you can't get stretchy fabrics or button hole elastic use two cloth ties and any fabric or elastic to make a headband.

Please open: PNWS Assembly Instructions.pdf

Please see the Sliced Files folder for files that are ready for cutting and printing

Intended Method - Fused Deposition Modeling

Acceptable Methods - Multi Jet Fusion, Selective Laser Sintering

Intended: Testing and design carried out on Prusa Mk3 and Prusa Mk3S

Acceptable: Any printer using the technologies stated above

mm (Detailed drawings for each part are provided)

1:1 scale

Preferred: PETG

Acceptable: ABS, PC, NYLON, PEEK, ULTEM, ASA or any other non-biodegradable polymer

Printer Dependant, 1 to multiple possible

1h 3m using 0.6 nozzle, 0.4 layer height, pre-programmed settings.

Slicing required prior to printing specific to user's printer.

- Layer Height = 0.3mm

- First Layer height = 0.2mm

- Perimeters = 2

- Top solid layers = 3

- Bottom Solid Layers = 3

- Fill Density = 15%

- Fill pattern = Rectilinear

- No support Material

- No Raft

This is generally identical to the Default PrusaSlicr 0.3mm Draft with the exception of reducing fill density to 15%.

If you experience stringing on your prints, drop your nozzle temp for all but the first layer by 5C

Post-process as needed in accordance with provided drawings.

There are a couple variations for this face shield, there is the shorty and the full variations which reduce mass while reducing the protection slightly.

The headband can also be swapped for the cloth tie clips and string or elasticated fabric

If you are manufacturing shields, please print one of these go gauges to help verify that your hole punches are good.

Individuals directly contributing to this design include:

- Alice Ferng

- Inna Turevsky

- James Gwertzman

- Jason Vandervlugt

- Jonny Flowers

- Jon Friedman

- Mandi Mckay

- Neil Cueto

- Tom L

- Troy Hutt

- Yasuhiro Wabiko