-

Notifications

You must be signed in to change notification settings - Fork 39

Hardware Installation Guide

Next Page The RF Capture Guide

Firstly see if your VCR or similar has been added to the list or just want real-world visual examples of tapped decks, below is the methods we use, but the guide overall focuses on basic soldering which has the most use from both a RF Tapping but also a basic repair skill perspective.

While soldering is encouraged and quite easy in practice as the vast majority of VCRs without 2.54mm headers have easy to get at standard bar/floating bar test points, so the soldering method opens up the most decks but the need to directly solder onto a VCR is not always needed, however it can make a nice clean practical upgrade with safe locking BNC ports.

It can be scary to some and to get started, we understand some people might not want to take an iron to there VCR, especially a higher-end one, but either way you go a clean setup requires proper cables and a proper electrical connection and soldering and melting/drilling a whole and adding a bulkhead protects the internal test points from snagged cables and the like.

Either way you go however this does not mean you can neglect the basics of cleaning your VCR heads, guides and checking it over, as it's a mechanical machine just like a car or any other tool it requires some level of care, like re-lubrication and regular cleaning below is a document on that.

This involves simple non-complex surface soldering of an signal and ground wire from test points or head amplifiers, with a 3.3uf to 10uf capacitor in-line to limit signal draw to allow normal playback for real-time reference capture during RF capture.

Sony/Sanyo decks normally have 2.54mm pin-header test points

(These cables can be made at home with RG316 & 26AGW copper wire via soldering iron, crimper & heat shrink)

DuPont Female to BNC / DuPont Male to BNC / SMA to DuPont Female adapters.

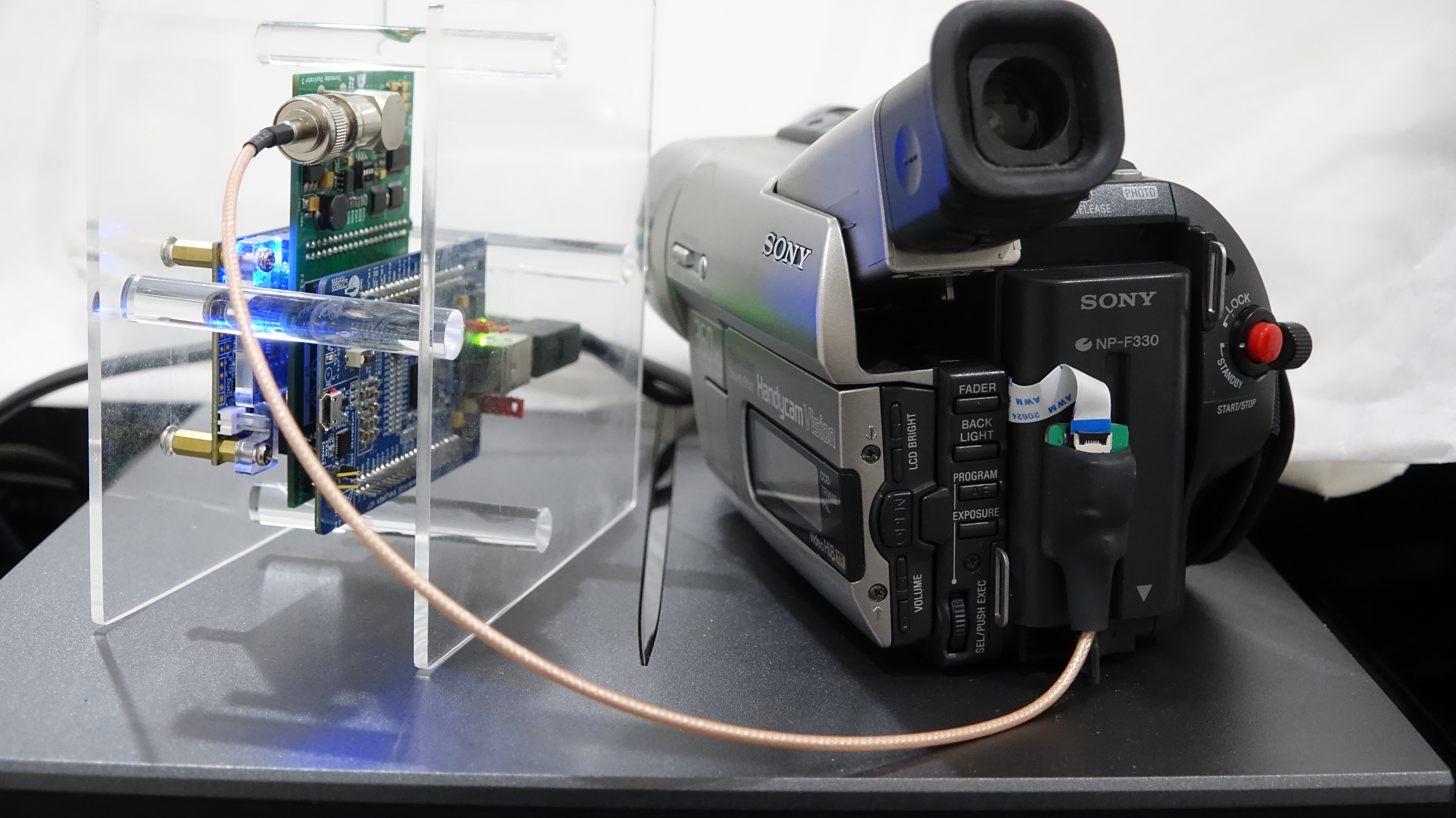

Example (This applies to VHS/Beta/Video8/High8)

If you go the Dupont pin method use an In-line Capacitor (Limits signal draw to allow for live playback alongside RF capture) AliExpress / Amazon US

BNC probes can be used for a solderless hook-up, but may not have as reliable signal and can easily be knocked free, unlike a soldered and mounted RF Tap.

BNC Alligator / BNC Hook / BNC Standard

BNC Banana + Banana Pin Probes

On most Sony Video8, Hi8 and later Digital8 camcorders that had support backwards playback, at the battery area, there is a rubber grommet or screw down plastic plate once removed this exposes the Jig connection point for testing this is normally 16/18/20 pin ribbon connectors with a 0.5mm pitch, a readily available and generic interface this is the go-to method for Video8/Hi8 tape formats.

Simply visually check your pin amount and buy the correct jig with the links below.

Check the service manual to see what pins have the RF signal, and your ready to go, however a cap may be needed in-line like any RF capture method.

Jigs (Unpopulated) / Jigs (With 2.54mm pins) / Flex Cables / DuPont to BNC / Type 1 USB Power Adapter / Type 2 USB Power Adapter

The NASA Standard of Soldering

Beginner's Guide to Soldering Electronics

How to use a Digital Multi Meter (DMM):

Voltage Measurement & Basic Usage

You will need the following items

-

Philips & Flathead Standard Screwdrivers

-

Side Cutters / Sharp Scissors

-

A Soldering Iron like the modern PIENCL / TS101 (With digital temp control)

-

USB Type-C PD 65~100w Power Bricks (with 3 pin earthing for ground) or PD 65w / 100w Power Banks / 12~24v Car Adapters

-

Heat Shrink / Electrical Tape / Hot-Glue / Silicone Sealant (For insulating cables and connections)

Optional but worth it for anything related to electronic's work

Modern Combo DMMs like the OWON HDS2102S / Link 1 / Link 2 are a True RMS Digital Mustimeter, Oscilloscope & a Waveform/Tone Generator in one unit.

-

Sn 60/40 Pb Leaded Solder (Good quality solder is key)

-

Flux MG Chemicals 8341 50ml jar recommended

-

Solder Wicking - Generic or SuperWick/GootWick

Here's the PINECIL with a built-up kit.

Here's the Rhaegon RJ2090 iron with what comes in the box. (Solder/Flux/Tweezers/Cleaning Spouge)

-

More TS100 Type Tips - For PINCEL/TS100/TS101 (Hotswap self heating tips)

-

More 900M Type Tips - For Hakko/Generic 900M Type Irons

-

More T18 Type Tips - For Hakko/Generic T18 Type Irons

-

More T12 Type Tips - For Hakko/Generic T12 Type Irons (Hotswap self heating tips)

NOTE You can get whole lower end kits like This for 15-25USD total, just get one with a grounded iron (has 3rd earthing pin), get a cleaner ball and some proper flux/solder and they will work okay for basic usage.

Note on White CX Cards you use the S-Video Luma pin for the RF input, this can be modified for a BNC if desired.

-

2-4x 50ohm BNC connector, normally a premade bulkhead, or solder able thread mounted.

-

10uf Capacitors standard assortment or audio grade like Nichicon if you like.

Note Having a 3rd arm holder with at least 2 metal clips is very helpful to hold connectors and the cable steady while soldering.

Note The RHAEGON iron generally comes in a kit with basic flux, cleaning spouge, 2 ESD tweezers and a roll of 240c melting point lead free solder, ware as the PINCEL can run off USB-C PD or DC power and tips can be hot swapped on the fly.

Note A clean & tinned soldering tip is a happy long lasting tip.

Note The In-line capacitor method is generally a coverall at the 10uf mark, 3.3uf-100uf range work fine but 10uf was standardised as its widely available and has worked perfectly with several VHS/SVHS/Betamax decks.

This is all you need for cleaning the head drum & VCR tracks boards and plastics even a light servicing can make a world of difference in reliability of a VCR.

-

99.9% IPA (Isopropanol/Rubbing alcohol) (Don't use on rubbers)

-

Wet Wipes & Paper Towels (General Cleaning)

-

Small dry Nail Wipes (Cleaning of VCR head/tracks/guides)

-

Printer paper (Cleaning of VCR Heads)

-

Cotton Buds (Q-Tips)

For initial board cleaning and removal of dust and other surface contaminants also recommended is:

-

WD40 Electronics Cleaner (Aerosol Liquid Version of WD40 basically)

-

Assortment of Brushes

-

WD40 Multipurpose Oil (Metal Bearings, Pinch Roller etc)

-

Super Lube® Multi-Purpose Synthetic Grease (PTFE) (Tape Guides, Plastics, Cogs) Loctite 399420

Note! for Betamax players using only alcohol-wetted paper is recommended for head cleaning as they will catch easily on anything else.

- Capacitor

- BNC Bulkhead

- RG316 Cable

Here is a £1 Coin & an AA Battery for size reference.

100uf 16v, 10uf 50v, 10uf 25v, - Electrolytic Capacitors (Caps) (Ceramic Recommended)

BNC Mountable Plastic Solder-able, BNC Bulkhead Metal Pre-Made.

Firstly before you start doing anything, check the model number on the top lid and back label use this to find the service manual.

Then disconnect power wait a few seconds and then remove the lid/top panel be careful around the edges on metal ones as stamped metal sheets can cut though skin if you run a finger across the edge carelessly but should slide off upwards from the back of most standard VCR units.

This varies based off year and market of the VCR modern later decks use more multirole IC's, ware as prosumer to rackmount units will have core parts for each processing task on dedicated boards and be majority though hole parts

Panasonic NV-HD630 For Example

Numbered Boxes In RED test point locations for signals.

-

TW3001 RF C - Video FM

-

TW501 FM Mix Out - HiFi FM RF

-

TW26 CVBS Out - Composite Video Output

-

TW3 CVBS Input - Composite Video Input

-

TW502 - ENVE (HiFi FM RF)

Left Hand Side

- Pink - TV Modulation & De-modulation pack

- Golden Yellow - Audio Processing (Nicam)

- Bright Yellow - Video Processing

Middle

- Purple - Head Amplifier Board

- Blue Box - VCR Loading & Playback Mechanical System or "Mech"

- Yellow Circle - VCR Head Drum & Connection Board

- Green Circle - Tape Guides & Guide Path

- Light Blue Left - Erase Head

- Orange Circle - Linear Audio or Edge Track Audio Heads

- Light Blue Right - Rubber Pinch Roller

- Brown Boxes Centre/Right - Head Drum RF Ribbon

Right Hand Side

- Red - AC Power Supply Stage

- Green - DC Power Supply Stage

Always Inspect & clean a VCR before running a tape though, it is the best first action, not only so you don't contaminant or break your tapes but your its self deck, if its in good working order and already been serviced just clean the heads.

Always remove the little head cleaner off the the side of the drum if there is one, as they are just dirt spreaders and can cause contamination.

Check that tape guide tracks are well lubricated if it looks shiny/bare then there's probably not enough.

Pinch rollers baring's can be lubricated with a drop of oil, and guides can be cleaned with wipes then use 99.9% Isopropanol.

Once cleaning has finished double check, if there is signal issues always good to check if there is cracked solder joints on the head drum from transport.

NOTE! Be careful to not touch the mains power supply area this can shock you and or kill you if you bridge the AC stage but generally, these have metal shielding and are isolated off to one side of the VCR always service equipment after it has been un-plugged and discharged of power.

Plastic back units can be marked and then poked through and slowly rimmed into a round hole via soldering iron at 340°C be careful not to overdo it, and cut the excess off with cutters for a flush mounting of your connector this is the easiest mod and looks very clean if you mark it properly.

Metal Units may require a 1/2-inch drill bit ideal for bigger Bulkhead pre-made cables this is useful on decks like the MD/AG/BR lines of SVHS decks which normally have blank or user-replaceable add-in module panels for external deck control boards.

Video FM RF / HiFi FM RF

This list is a work in progress based on service manuals and direct user experiences and may not include every possible name but covers the majority of VCR's PCB board & service manual wording wise.

Note!:

Most decks will also have a composite test point which can be useful for adding a composite output/input on SCART-only decks.

Note!:

If your VCR was serviced likely there are some pen marks on the board at test point locations.

Video FM RF Signal:

RF C, RF Y, RF Y+C, V RF, PB, PB.FM, V ENV, ENV, ENVE, ENVELOPE, VIDEO ENVE, VIDEO ENVELOPE

HiFi Audio FM Signal:

HiFi, A.PB, A FM, A.PB.FM, Audio FM, A-Out, A ENV, HIFI Envelope, FM Mix Out

Follow the yellow brick road (The Contrasting Line Indicators)

In modern manuals the servicing book will directly correspond to labels physically on the boards in older manuals, they will look like TW1000 but be TW1 on the boards label or silkscreen.

For example, HiFi on the AG-7150 is TP4707 in the manual but just 707 on the label it's sometimes confusing if you're not used to reading them or probing every test point.

There is always contrasting arrows showing the signal path on service manual diagrams, trace the line to find test points along the signal path.

Heads --> Amplfication --> Test Points --> Video Processing --> Video Playback

Note: Sometimes both test points can be called ENV.

Test points vary in type generally all are through-hole, but SMD pad style is also a thing.

Consumer Decks will have bar style and floating bar style test points with floating being easy to probe but bar style generally needs fine tip probes.

Prosumer & Professional decks typically have hook-to and poll-style easy test points to solder to and are easily user accessible.

Sony Decks from VHS to Betamax will have 2.54mm headers for DuPont Connector or breakout jig use.

Video8 & Hi8 devices have service jig points via universal flex cables.

Is the best for fixed backports with a locking and reliable connector used in everything from 1960's communications gear to current-day cine cameras, this is the most preferred connector due to reliability.

Is a flat external-sided, threaded locking connector found in almost all common consumer RF devices such as 4G/5G, Wifi Dongles, Handset radio units a small and versatile connector for internal use not the most physically strong for external use.

Note

RP stands for reversed polarity so the signal is on the ground and the ground is internal these pins are respectively also re-versed for these connectors.

Is the lesser-known sibling of SMA but it's a tighter than TS-9 style non-locking connector.

Also called DIN 1.0/2.3 Is the smallest locking knock-safe connector seen on portable equipment like PCIe cards and field recorders (Reference Part Number: 45K201-400L5)

These are the most widely known connector technically called a 2.54mm Header Pin these are used for kid's kits to diagnostic test points or low-power/data connectors for computer hardware such as fans or Molex power, these normally use 26AGW wire.

With FPC Flex ribbon Cables jig points are broken out to dedicated pins, on basic PCB boards.

-

Pick your cable type, and decide on bulkhead type.

-

RG316- Thicker used used on most 50ohm pre-made cables -

RG178thinner and more flexible for internal use. -

Note both have practically the same performance in terms of RF signal at

50~100cmof length, most taps are under30cm. -

Premade BNC bulkheads can be chopped and cut to size, allowing you to mount first and solder later once routing is planned.

Metal decks will normally need a drill press, but plastics decks can be easily melted.

Cut away excess and flush mount your BNC connectors.

After finding the best places for the BNC bulkheads and test fitting them you can then route your cable to the necessary length.

Measure with 5-10cm of slack your cable run from your test point to where you would like to mount your BNC on your unit normally this is at the back and or next to the normal audio and video output ports.

-

Prepare your iron at

280-320°Ckeep it tinned until ready for use, then clean apply new solder. -

Measure about 3cm of cable length and mark it with a pen or your iron.

-

Stripping your wire, use a pair of automatic wire strippers or your iron at

320°Cthe outer insulation layer will melt so you can rim around the outer cable then carefully pull it off with tweezers or fingers. -

Pull back the strained outer wire and twist it together.

The inner insulator is easier to pressure the cable with the tip of your iron against a surface like ceramic in a pulling motion and you will easily strip the insulation off, though

NOTE! without fluxing & tinning this wire you may have insulation residue, automatic wire strippers are more suited for this task but can be slightly tricky with RG316.

- Twist the inner wire strands and tap the end with a bit of solder, this stops the wire from fraying.

If a premade bulkhead is used you can solder the inner wire to a capacitor and then solder that to the board which can be helpful as you can hold the capacitor with tweezers or a finger.

-

Clean and flow some fresh solder onto your Iron.

-

To flow solder into the middle pin, add a small dab of flux into the middle pin hole.

-

Double back your cable if using RG178, holding the connector the cable inside the connector, then add some more solder to your Iron and gently press into the open end of the connector this will in 1-2 sec flow solder correctly.

-

Wipe excess flux off and insulate with hot glue and or heat shrink.

You can do this with electric tape, heat-shrink, hot glue, silicone sealant once you know you have a good weld on the signal and ground solder joints this stops stray contact with dust and other wires.

- BNC Male to DuPont Female cable

- In-Line Splice Method adding an ceramic in-line to the signal wire

- BNC DC Blocker Adapter AliExpress

Example Used Panasonic NV-HD630

This is very simple in practice.

- Set your soldering iron to

280~320°C

- Lay your capacitor next to flat bar types or curl one leg around for floating/poll types.

- Apply flux to the joint, then liquify with a touch by your iron and ensure position is correct.

- Apply solder to your iron, a bevel tip is better then rounded for this use but either work fine.

- Apply tinned iron to your joint and allow 1-2 seconds to flow then move your iron away, it is easy to knock flat bar types so its best to ensure the legs lay perfectly flat to the board level with the test point.

-

Always clean your soldering area with 99.9% IPA after you are done to remove any flux.

-

Clean Your Tip

- Tin your Tip and disconnect your iron for storage, the coat helps protect it from rusting.

Example Used Panasonic NV-HS1000 & Panasonic NV-HS950B

-

If you can do pin-push method on a amplifier board then manipulate the legs with tweezers carefully.

-

Strip your RG Coax cable and twist the grounding together and apply flux to it

-

Solder your grounding to the exterior shield of the head amplifier

-

Route your cables to the back of the VCR to BNC Bulkheads or though vents.

Older examples with electrolytic caps.

(If both are even then this is a non-polarised cap and does not matter)

You can test your test points with a 10-sec capture at this point with no displays connected via probes.

Once your test points have been located depending on your available space you will most likely want to line up your 3.3-100uf range capacitor to the test point holding it down with tweezers or via tape/hot glue.

Polymer and ceramic capacitors, these are not polarised so which of the 2 legs are used does not matter, for electrolytic capacitors the negative leg goes into the test point and the positive to your cable.

Lay your capacitor next to for bar style or wrap half around for poll style

NOTE! The Negative leg is always the shorter of the two which makes it easy to visually identify.

Using an easy example here, as the rackmount decks have removable Audio/Video cards.

Cold joints are soldered joints ware the metals don't make a proper weld to eachouther, and ball up or look dull.

Example Used: Pannasonic AG7150 & Pannasonic NV-HS950B

-

Line up your capacitor to the test point, make a 90 degree U bend then cut the excess off.

-

Apply flux to the test point to ensure good solder flow.

-

Tin your iron and give it a clean, then tin again and flow some solder onto your leg and test point leg wire.

-

Run the outer shield to the ground or run a separate cable for grounding.

-

(Coax shields the signal wire with its grounding path wire)

-

If possible mount to BNC bulkhead or hijack an redundant CVBS BNC

Sony 8mm Camcorders

Sony-Hi8-CCD-TRV66E

Sony-Digital8-DCR-TRV840

Panasonic NV-HS950B TBC Card Video ENV Tap routed though the frame.

Panasonic-HD630 Video/HiFi FM & CVBS mounted to BNC Bulkheads.

For CX Cards use the Luma Pin with an S-Video breakout cable, or BNC if modified.

Use 50Ohm cables or a direct coupler for DomesDayDuplicator.

Please note RF Capture is not limited to the listed devices there is other USB/PCIe/TB3 based SDRs.

Next Page The RF Capture Guide

- FAQ - Frequently Asked Questions

- Diagram Breakdowns

- Visual-Comparisons

- VCR Reports / RF Tap Examples

- Download & Contribute Data

- Speed Testing

- Visual VBI Data Guide

- Closed Captioning

- Teletext

- WSS Wide - Screen Signalling

- VITC Timecode

- VITS Signals

- XDS Data (PBS)

- Video ID IEC 61880

- Vapoursynth TBC Median Stacking Guide

- Ruxpin-Decode & TV Teddy Tapes

- Tony's GNU Radio For Dummies Guide

- Tony's GNU Radio Scripts

- DomesDay Duplicator Utilities

- ld-decode Utilities