New issue

Have a question about this project? Sign up for a free GitHub account to open an issue and contact its maintainers and the community.

By clicking “Sign up for GitHub”, you agree to our terms of service and privacy statement. We’ll occasionally send you account related emails.

Already on GitHub? Sign in to your account

M109 and M190 Injected after PRINT_START macro #875

Comments

|

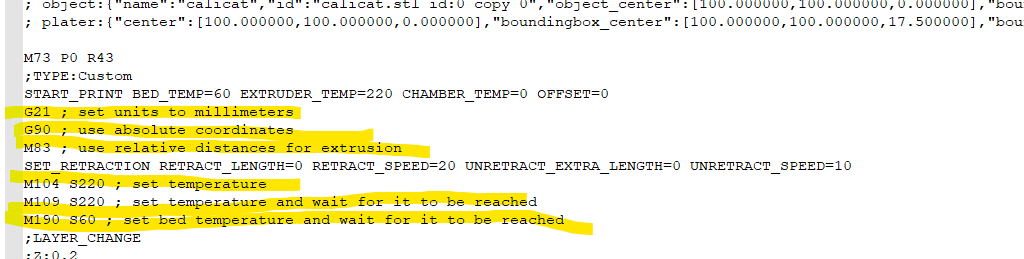

I use this as my printer tab custom g-code: Here is my Klipper macro: I also use Klipper as the firmware flavor w/ machine limits disabled. |

|

Hey @ProfEngr, Thanks for wanting to help, but I think you misunderstood my issue. Because if I’d use what you have there I’d still have the same problem. Because there would still be a M109 and M190 after the PRIME_LINE. |

|

I had something similar to this a while back. That's why I have the bed and nozzle temp variables specifically called out in the custom section. It was an issue w/ the firmware flavor I was using at the time. I just left it in because it kept working. |

|

I wonder if these lines: SuperSlicer/src/libslic3r/GCode.cpp Lines 1406 to 1410 in 201c612

SuperSlicer/src/libslic3r/GCode.cpp Lines 1320 to 1328 in 201c612

Edit: I believe those new lines were added with ca3d823 |

|

I confirm, I got the same unwanted behavior. This come from PrusaSlicer -> if you don't put explicitly M109/M190 into the custom start gcode of the slicer, it will add it for you as a security for Marlin printers. This is a regression in SuperSlicer coming from the last PrusaSlicer merge I think. |

|

I'm going to add a settign to force disable auto-added heating lines. Problem is I also have report of "printer not heating" bugs. |

|

Thanks Merill! I'll close when I get to testing it :) |

|

@supermerill Sadly gotta report that the function is currently broken in the C/C++ Nigthly windows x64 C/C++ Nigthly windows x64 #296. |

|

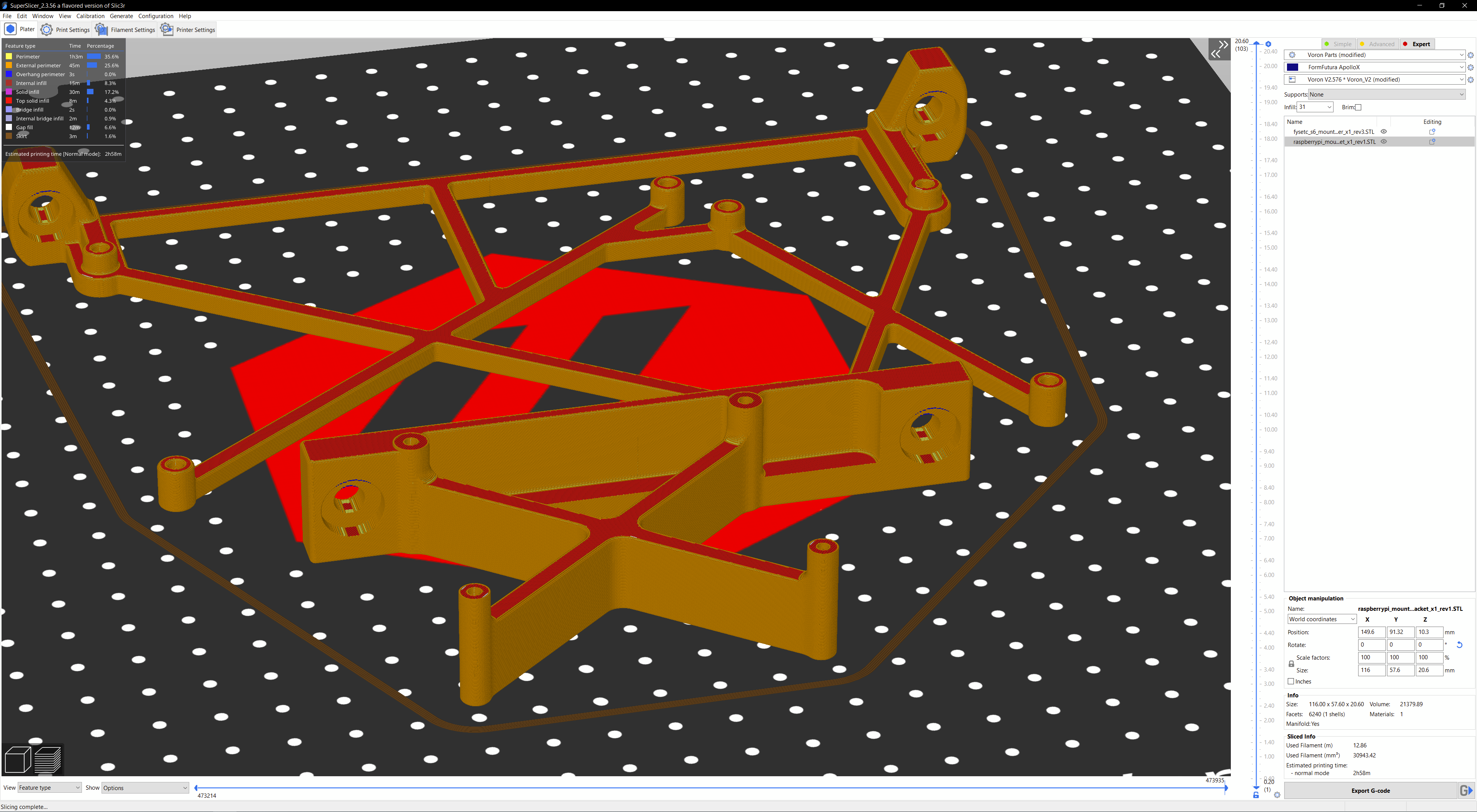

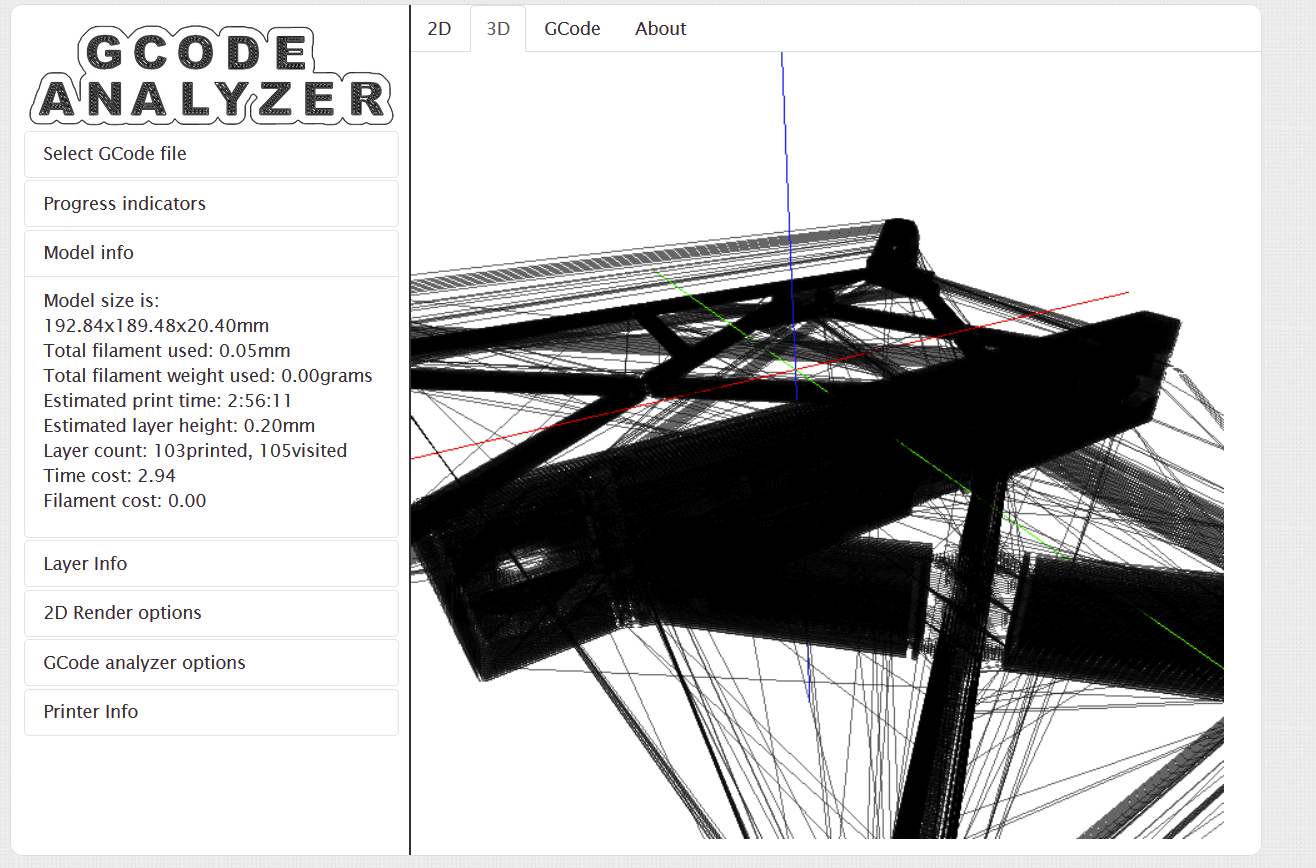

@MarcPot everyhting is fine. are not written with the 'only custom gcode' so be sure to have them in your start gcode! also there is a M104 & 140 a bit alter in the print with the option activated, but it's nothing to be worry about, imo. But you're right that the code viewer misses the header if it's hidden in your macro. I should create one for the gcodeviewer. |

|

You're right, should've looked at the files instead of the viewers. Closing this issue since it has been resolved and the bug is unrelated to the issue. |

Version

2.3.55.2

Operating system type + version

Windows 10 64bit

3D printer brand / version + firmware version (if known)

Klipper

Behavior

When using the Klipper gcode flavour there is still a M109 and M190 after my PRINT_START macro.

This causes the printer to wait a sec or 2 after my print start (purge line), causing it to ooze before starting the actual print.

The reason for the printer to wait is because it's not always exactly within the M109 range.

A solution would be an (expert mode) checkbox to disable everything between

; custom gcode end: start_gcodeand;LAYER_CHANGEI guess you could also make SS detect if you're giving temps to your print_start, but I don't think this would be as friendly for beginners.

Project File (.3MF) where problem occurs

Shape-Box.zip

The text was updated successfully, but these errors were encountered: