-

Notifications

You must be signed in to change notification settings - Fork 12

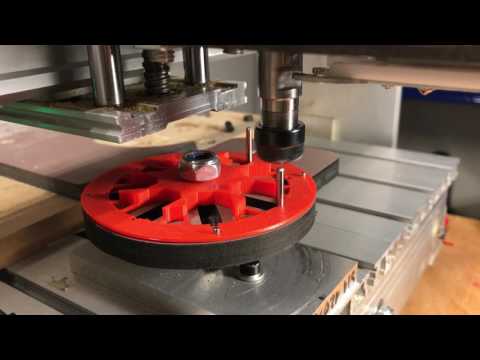

XATC Carousel

The XATC Carousel is the central component for an XATC. This part will screw and unscrew the collet nut and hold the endmill's. To screw or unscrew, we use an "magical move", this is just an arc move.

- 1x Milled part of carousel 10mm HPL Download

- 1x 3D printed part of Catchframe Download

- 1x threaded rod M10

- 3x screw nuts M10 (1x self lock)

- 1x Aluminium plate 8mm thick, ~100x60mm

- 2x M5 DIN916 screws and nuts

to make a fast and lightweight replace of your "M6 TX" (toolchange) commands, i wrote a small perl script. This parse your gcode file local(!) and send and replace the M6 lines with my XATC gCode via server api.

It managed automatic the tools to get or put. I.e. You used Tool number 3 for last cut and will change to T4, then parse.pl will manage this for you. This means it get the put process for tool number 3 and get process for tool number 4.

Ok, here an complete example to use this script on a linux (Raspberry o.a.):

curl -s https://raw.githubusercontent.com/xpix/xatc_api/master/parse.pl | perl /dev/stdin t/TestXATC.gcode > xatc.gcode

You can test this with this Test gcode file: https://raw.githubusercontent.com/xpix/xatc_api/master/t/TestXATC.gcode

- Fusion 360: http://a360.co/2nmr1Sv

- Material: HPL 10mm

-

Drill and Tap an M10 thread in the center off base plate.

-

screw the alumium base plate to the bed of your CNC machine

-

screw the threaded rod in this base plate

-

screw wrench on bearing, i used a POM piece and drill holes in wrench and holder

-

use servo horn to hold wagon of linear bearing in position

-

grind 2 of the nut's close to the hole

-

use 2 threaded rods and install platform on cnc3040