-

Notifications

You must be signed in to change notification settings - Fork 54

Example 13 : Silo

This example performs a three-dimensional discrete element method simulation of filling and evacuation of a silo [1]. We use a stopper at the bottom of the silo to pack the particles. After filling the silo, we remove the stopper and let the particles to leave the hopper.

Total simulation time is equal to 40 s, while time-step, log frequency and output frequency are set equal to 0.00001, 1000 and 1000, respectively:

# --------------------------------------------------

# Simulation and IO Control

#---------------------------------------------------

subsection simulation control

set time step = 1e-5

set time end = 40

set log frequency = 1000

set output frequency = 1000

end

We use checkpoints to write the simulation information every second. If the simulation breaks or we need to pause it, we could use the checkpoint to resume the simulation instead of restarting it.

#---------------------------------------------------

# Restart

#---------------------------------------------------

subsection restart

set checkpoint = true

set filename = sliding_restart

set frequency = 100000

end

In the model parameters section, particle-particle and particle-wall broad and fine search frequencies are defined. We also define the particle contact search size (neighborhood threshold), contact forces and integration methods. The contact detection method is dynamic, and it needs dynamic contact search size coefficient (a safety factor for dynamic contact search). Load-balancing redistributes the computational load on the processors every 2 s, in case of parallel simulations to decrease simulation time.

# --------------------------------------------------

# Model parameters

#---------------------------------------------------

subsection model parameters

set contact detection method = dynamic

set dynamic contact search size coefficient = 0.8

set load balance method = frequent

set load balance frequency = 200000

set neighborhood threshold = 1.3

set particle particle contact force method = pp_nonlinear

set particle wall contact force method = pw_nonlinear

set integration method = velocity_verlet

end

In the physical properties section, the physical properties of particles and walls, including diameter and density of particles, Young's modulus, Poisson's ratios, restitution coefficients, friction and rolling frictions of particle and wall are chosen. The gravitational acceleration is also set in this section. Diameter of particles in this example is 5.833 mm. The experiments [1] used non-spherical barley grains. We used spherical particles with the same volume. Total number of particles in this example is 132300.

#---------------------------------------------------

# Physical Properties

#---------------------------------------------------

subsection physical properties

set gx = 0.0

set gy = 0.0

set gz = -9.81

set number of particle types = 1

subsection particle type 0

set size distribution type = uniform

set diameter = 0.005833

set number = 132300

set density particles = 600

set young modulus particles = 5000000

set poisson ratio particles = 0.5

set restitution coefficient particles = 0.7

set friction coefficient particles = 0.5

set rolling friction particles = 0.01

end

set young modulus wall = 5000000

set poisson ratio wall = 0.5

set restitution coefficient wall = 0.7

set friction coefficient wall = 0.5

set rolling friction wall = 0.01

end

Next, we define the insertion properties, which are insertion method, inserted number of particles at each insertion step, insertion frequency, insertion domain and other information regarding the initial positions of particles inside the insertion domain.

#---------------------------------------------------

# Insertion Info

#---------------------------------------------------

subsection insertion info

set insertion method = non_uniform

set inserted number of particles at each time step = 20000

set insertion frequency = 20000

set insertion box minimum x = -0.37

set insertion box minimum y = -0.042

set insertion box minimum z = 0.9

set insertion box maximum x = 0.37

set insertion box maximum y = 0.007

set insertion box maximum z = 1.09

set insertion distance threshold = 1.5

set insertion random number range = 0.1

set insertion random number seed = 19

end

We use a mesh file for this simulation. Gmsh [2] generates this mesh file.

#---------------------------------------------------

# Mesh

#---------------------------------------------------

subsection mesh

set type = gmsh

set file name = ./silo.msh

end

We define a stopper to pack the particles during filling. The stopper locates at z=0 m. We remove the stopper at t=4 s to start silo evacuation.

#---------------------------------------------------

# Floating Walls

#---------------------------------------------------

subsection floating walls

set number of floating walls = 1

subsection wall 0

subsection point on wall

set x = 0

set y = 0

set z = 0

end

subsection normal vector

set nx = 0

set ny = 0

set nz = 1

end

set start time = 0

set end time = 4

end

end

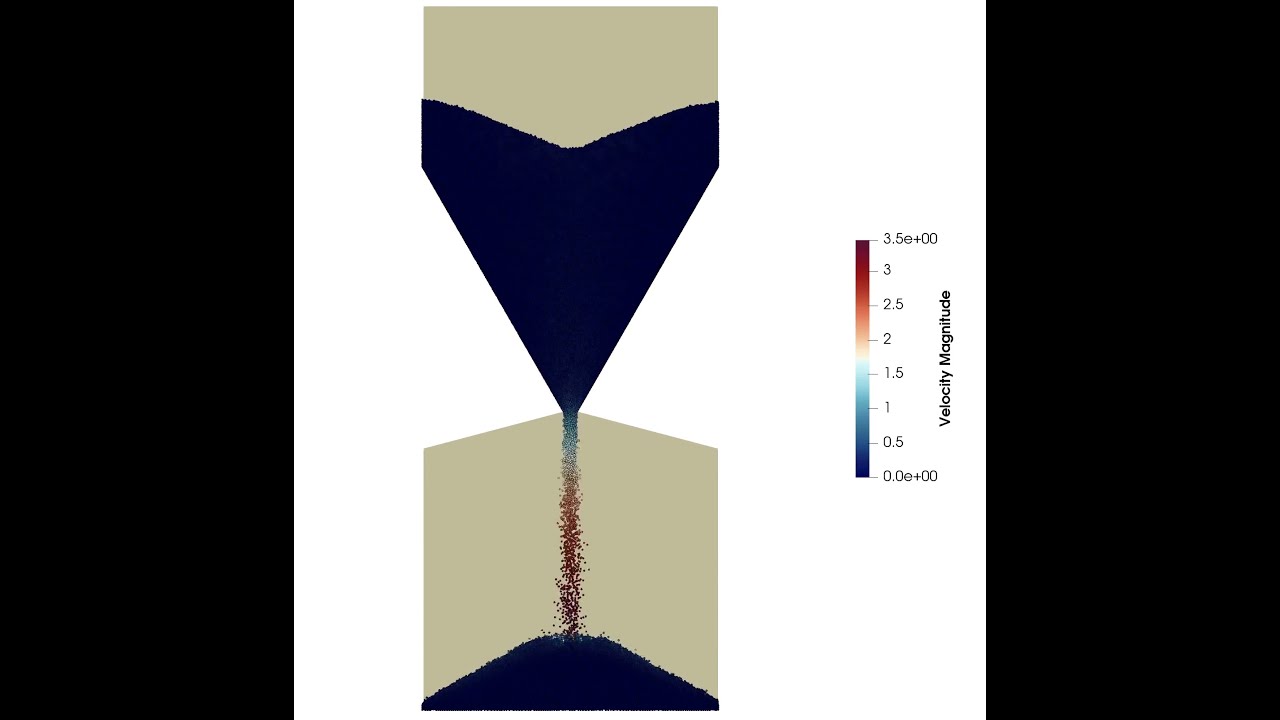

dem_3d solver simulates this example. A snapshot of the silo during evacuation of particles:

Watch the animation of this simulation:

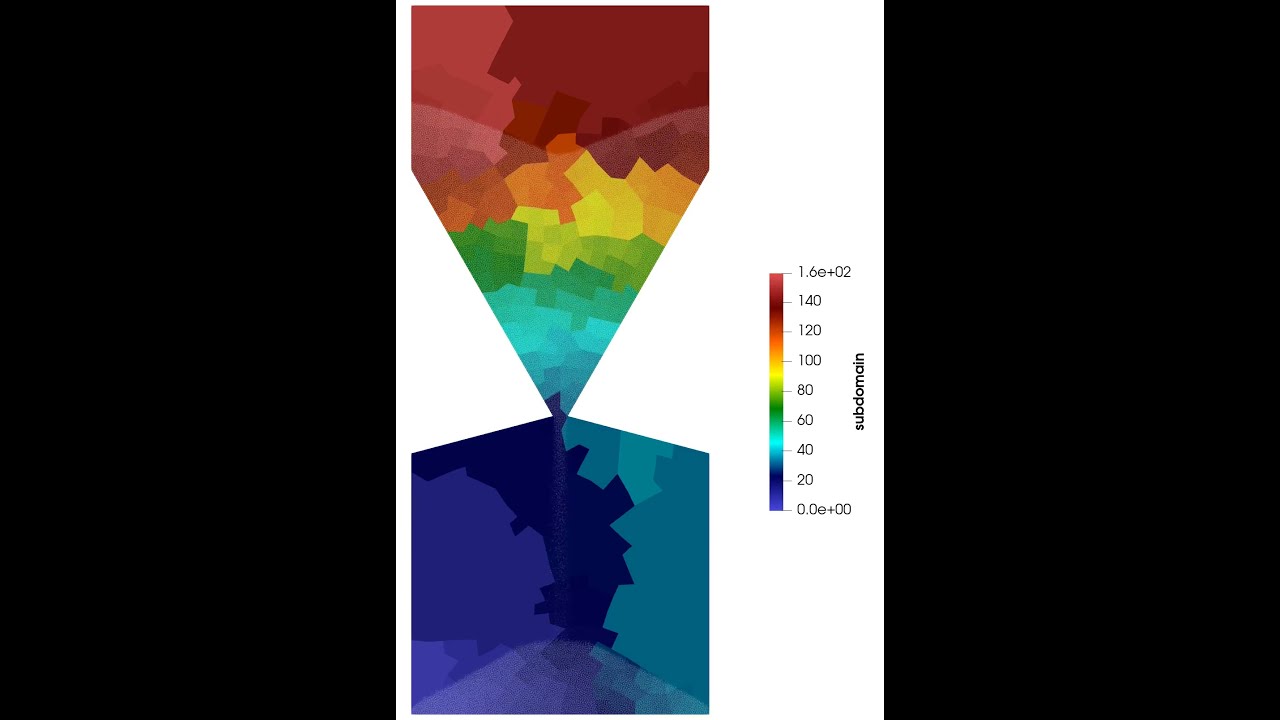

Watch the dynamic distribution of domains in a simulation on 160 processes. As particles move inside the simulation domain, load-balancing equalizes the load on the processes.

[1] Golshan, S., Esgandari, B., Zarghami, R., Blais, B. and Saleh, K., 2020. Experimental and DEM studies of velocity profiles and residence time distribution of non-spherical particles in silos. Powder Technology, 373, pp.510-521.

[2] Geuzaine, C. and Remacle, J.F., 2009. Gmsh: A 3‐D finite element mesh generator with built‐in pre‐and post‐processing facilities. International journal for numerical methods in engineering, 79(11), pp.1309-1331.