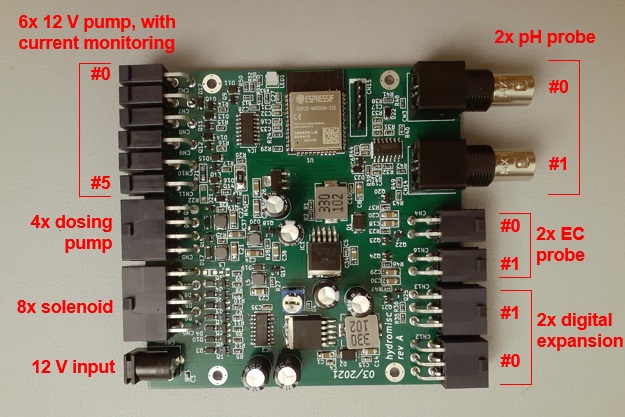

This is a single PCBA with all the necessary I/O to automate a typical small to mid-size hydroponic grow, controllable over Wi-Fi. It may also be suitable for aquariums, ponds, or any other biological or chemical process involving water treatment. Inputs and outputs include:

- 8x 12 V, 1 A outputs, intended for solenoid valves (but usable for other actuators too)

- 6x 12 V, 0.5 A ouputs, intended for pumps, with current monitoring

- 4x 12 V, 0.25 A outputs, intended for peristaltic dosing pumps, with analog voltage control

- 2x direct interfaces to a pH probe or other ion-selective electrode

- 2x direct interfaces to an EC (electrical conductivity) probe, reading around 1000 uS

- 2x direct interfaces to a resistive sensor (thermistor, photoresistor, etc.), reading around 10k

- 2x digital interface to a temperature and humidity sensor

- 2x digital interface to a strain gauge (to measure weight or pressure)

Typical hydroponic practice is to maintain the solution at a target EC and pH, using EC as a proxy for fertilizer concentration and dosing acid or (rarely) alkali to adjust pH. I'm using this board now to control injector pumps in a drain-to-waste system, open-loop with manual adjustment, and also to maintain closed-loop EC and pH in a recirculating system.

The board is managed by an ESP32. Install the ESP-IDF framework from Espressif, and build and load the firmware from an ESP-IDF command prompt.

The board is a Wi-Fi client. The name and password for its access point

must be compiled in to the program, in Espressif's usual way, with idf.py menuconfig. The board will automatically get an IP address over DHCP,

so you'll probably want to configure your router or other DHCP server to

assign a static IP based on the MAC address. The MAC address is unique

per board, since that's serialized in the ESP32 module.

The current firmware implements a simple interface to read the sensors and write the actuators over http. I'm currently sequencing everything with some shell scripts initiated by cron jobs on a Raspberry Pi, which invoke curl to command this board. Any device and programming language capable of making http requests could be used, though.

The outputs are described as "solenoid", "pump", and "dosing pump", because that's the purpose for which I'm personally using them, and the present interface is named around that model. They can of course be used for other types of load too. The software interface is easily extended if the present commands are inadequate or too confusingly-named.

$ curl 'http://hydromisc/solenoid?k=3&t=20&'\

'dosingA=90&dosingB=90&dosingPh=210&dosingAux=0'

{ "result": "solenoiding" }

Solenoid output k is energized for t seconds. For the same period, the four dosing pumps are also energized, with the respective duty cycles from 0 (off) to 254 (full on, ~12 VDC). The voltage applied to the dosing pump is very roughly linear in duty cycle, but both that map and the map from voltage to speed are quite inexact. If you're closing the loop (e.g., dosing acid to achieve a particular pH), then this may not matter, since your control loop will automatically correct that. If accuracy is important, then the pump should be calibrated, for example by measuring the amount of liquid dispensed using a graduated cylinder or weighing scale.

The solenoid output is powered for three seconds after the pumps stop. This is to avoid closing the solenoid valves with pressure in the system, since the pumps will continue to operate briefly after losing power. If the dosing pumps feed directly into a single reservoir, then this and everything else about the solenoids may be ignored.

$ curl 'http://hydromisc/pump?k=4&t=15'

{ "result": "pumping" }

Pump output k is energized for t seconds. The measured current (up to about 500 mA) is recorded.

$ curl 'http://hydromisc/current'

{ "result": "current","current": [ 71, 65, 74, 69, 78, 74, 80, 73, 63,

73, 65, 68, 74, 64, 60 ] }

The current from the most recent /pump is reported, in units of milliamps at one sample per second. If this hasn't yet completed, a full-length trace is reported but future samples are 0.

$ curl 'http://hydromisc/stop'

{ "result": "stopping" }

All (solenoid, pump, dosing pump) outputs are de-energized immediately.

$ curl 'http://hydromisc/sensors'

{ "result": "sensors", "ec0": 984, "ec1": 47, "ph0": 41, "ph1": -320,

"dcr0": 210000, "dcr1": 210000, "temp0": 25.7, "humidity0": 54.0,

"temp1": -9999.9, "humidity1": -9999.9, "sg0": 0, "sg1": -1 }

All sensors are measured and reported.

The pH electrode voltage is returned in millivolts, and your software must convert to pH. To a first order, the map from voltage to pH is linear, with zero volts corresponding to pH = 7.0, and a slope around 59 mV/unit around room temperature (which may be calculated using the Nernst equation).

You should calibrate by measuring the voltage in two solutions of known pH (e.g., 4.0 and 6.9), and interpolating linearly between the two. For example:

const V69 = 8; // millivolts in pH 6.9 calibration buffer

const V40 = -152; // millivolts in pH 4.0 calibration buffer

const slope = (V69 - V40)/(6.9 - 4.0);

let ph = 6.9 + (resp.ph0 - V69)/slope;

Your software must also correct for temperature if desired; though in typical hydroponic applications, the pH is close enough to neutral that it doesn't matter too much. To a first order, the slope changes with temperature but the offset does not, so the tempco is very small when the output voltage is small.

Other ion-selective electrodes (e.g., for nitrate, potassium, etc.) should also work with this interface circuit. Consult the electrode documentation for the calibration procedure, which should be specified in terms of millivolts from the meter. The reference electrode would need to go to the BNC shell (Vref ~ 1.2 V), not ground.

EC is returned directly in microsiemens, uS. For example, a resistance of 1kohm is equal to 1000 uS. Your software must convert based on the cell dimensions (to convert from uS to uS/cm; a cell constant of 1 cm is typical so that may be trivial), and also perform any temperature compensation if desired. If you already have a different EC meter, then you can use that with a sample of hydroponic solution to transfer calibration. If not, then you can calibrate in a solution of 1000 mg/L sodium chloride (table salt), which has conductivity of 2000 uS/cm at 25 degrees Celsius.

In concept, any two wires the right length and distance apart (e.g., on the order of 1 cm) could be immersed in solution, and could serve as your EC electrode. You may prefer to buy a purpose-built electrode, though. That may have a plastic sheath that protects the electrodes from mechanical damage with a slit to avoid trapping air bubbles. The electrode material should also have good electrochemical properties. Inexpensive electrodes will generally use stainless steel. The most expensive electrodes will use a thin coating of platinum black, which reduces error by reducing the series resistance due to electrode polarization. Either is likely fine in practice.

Electrodes may also be inserted into media, in which case they measure a product of the solution EC and the media water content. An EC channel can also be used as a binary liquid level sensor, by placing the electrodes just below the threshold level. In such use, take care that the electrodes are far enough apart that surface tension can't hold a drop of solution even when they aren't immersed.

To measure water (or other) temperature, you can use a thermistor. Some EC or pH probes will have a thermistor integrated in the probe, or you can buy one separately. The resistance of that thermistor (or any other resistive sensor) is returned directly in ohms. Your software must convert to temperature. For a typical NTC thermistor, the logarithm of the resistance is proportional to the reciprocal of absolute temperature. For example:

// we calibrated at 22 degrees Celsius, and measured 10435 ohms

const calLogR = Math.log(10435);

const calTemp = 22;

// from some random NTC thermistor datasheet, or you could also do a

// two-point calibration

const slope = 0.0002578;

let Tinv = 1/(273 + calTemp) + slope*(Math.log(resp.dcr0) - calLogR);

let T = 1/Tinv - 273;

I'm also using that interface with a photoresistor to count hours of sun, though I'm doing a simple binary threshold (to distinguish direct sun vs. shade) and not a full continuous calibration.

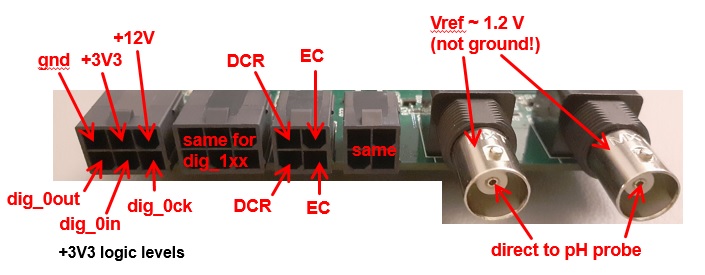

To measure air temperature and humidity, connect an AM2301 on either 2x3 position connector to ground (black), +3V3 (red), and DIG_xOUT (yellow). Temperature is returned in degrees Celsius, and humidity in percent RH. A pull-up resistor from red to yellow may be required if the wires are long, since we otherwise just get the ESP32's on-chip pull-up.

To measure a strain gauge, connect an HX710 to ground, +3V3, DIG_xCK (SCK), and DIG_xIN (DOUT). The result is returned in raw ADC units, which you can calibrate to force or pressure with a linear offset and scale. I use this to measure liquid level with a "bubbler" system, measuring the hydrostatic pressure in an air-filled tube at the bottom of the tank. (It's necessary to bubble a slow trickle of air through the tube, or else tiny leaks will cause it to eventually fill with water; but since I'm already aerating my tanks, that just takes a tee and a needle valve. Such systems are common in process industries, crude but cheap and reliable. My system is okay but not great, since the pressure sensor has a large tempco. I used an additional AM2301 very close to the sensor to compensate, but there's still an inch or so worth of residual error.)

You can simultaneously connect an HX710 and an AM2301 to the same 2x3 connector, since they use different data pins.

$ curl 'http://hydromisc/conf?dosingAPhase=63&dosingBPhase=4032&'\

'dosingPhPhase=4095&dosingAuxPhase=4095&runBigPump=1'

{ "result": "configured" }

By default, the dosing pumps run continuously during a /solenoid call. Here they can also be configured to run intermittently, in 100 ms intervals on a 12-interval (1.2 s) period. The operation of each dosing pump may be specified here as a bitmap, 12 bits as a decimal number. For example, the decimal number 63 is equal to 12'b000000111111, so dosing pump A is on with duty cycle 1/2, 600 ms on followed by 600 ms off. The decimal number 4032 is equal to 12'b111111000000, so dosing pump B is also on with duty cycle 1/2 but with opposite phase.

When peristaltic pumps are used as fertilizer injectors, this intermittent operation can achieve lower injection rates than can be reliably achieved with low pump voltage (since the transfer characteristic from voltage to flow varies a lot at low voltage). The phase may be chosen to minimize risk of mixing before dilution.

By default, the output BIG_PUMP is energized during a /solenoid call. This may be disabled by setting runBigPump=0.

For the moment, this hardware isn't commercially available in assembled form. (That may change, since this is open hardware that anyone can build and sell; I'll add links if and when it does.) You'll therefore have to buy the bare PCB and parts kit, and assemble yourself. This PCBA has no leadless or fine-pitch components, so it can be hand-assembled with a soldering iron and moderate skill.

Note that rev A of the PCB has one major erratum, a missing pull-up on ESP32_EN, plus some smaller issues that degrade analog performance. I've corrected these in rev C, which is the head revision in git, but never actually built and tested that. So it's possible there's still a mistake, though the risk should be small. Full details of the changes are in board/README.md.

Total cost to build one board is around:

| Item | Cost |

|---|---|

| bare PCB, PCBWay | $30 |

| components, Digi-Key | $60 |

All connectors are Molex Mini-Fit Jr., a very popular series. It's possible to solder the cable-end connectors rather than crimping them, but not recommended. The official crimp tool is expensive. I've used a third-party "SN-28B", which isn't actually designed for that family but is cheap and barely adequate, if I crimp first with the largest die and then again with the middle one.

To program the board, use any USB-to-serial adapter with +3V3 logic levels, for example an FT232R. Take care that you need access to RTS, which some such boards and cables don't break out. On CN15, connect:

- ground to ground

- +3V3 to nothing

- USBSER_RX to ESP32_TXD0

- USBSER_TX to ESP32_RXD0

- USBSER_DTR to ESP32_IO0

- USBSER_RTS to ESP32_EN

Program with idf.py flash in the usual way. Disconnect digital expansion

devices when programming, since they can interfere.

For complete automated control of EC and pH, you might add:

| Item | Cost |

|---|---|

| pH electrode, Yieryi | $15 |

| EC electrode | $15 |

| 3x aquarium-type dosing pump | $30 |

| water fill solenoid valve | $15 |

See my brief review of the sensors and actuators now cheaply available on Chinese markets.

Then you might periodically (e.g., minutes to hours) measure EC and pH with /sensors. You could also monitor solution level, using another EC electrode positioned high in the tank or using a float switch. The board has no binary digital inputs, but the DC resistance or EC channels work with switch contacts too. Then using /solenoid, you could add water, fertilizer, and acid as required to maintain desired liquid level, EC and pH.

You would typically aim to keep pH constant, for example with simple hysteretic (bang-bang) control--add phosphoric if the pH is too high, or add potassium carbonate if the pH is too low, with a significant deadband (e.g., 0.5 units) so the acid and alkali don't fight it out and leave too much potassium phosphate in the solution. In most cases the alkali would actually be unnecessary, since the natural alkalinity of the water supplies all necessary pH rise. That's the reason why only one dosing pump channel is labeled "pH", though the AUX channel could be used for alkali if desired.

Control of EC is more complicated, since unwanted ions (e.g., sodium and chloride) will accumulate over time in the solution. So constant EC probably means rising unwanted ions but falling NPK, and will eventually result in deficiency. If you maintain constant EC, then you'll need to change the reservoir often. You can waste less water by allowing slow rise, though managing that without detailed water analyses is somewhat uncertain. In all cases, fertilizer should be dosed in a way that doesn't risk mixing of Part A and Part B before they're fully diluted, to avoid precipitation (nutrient lockout) from the reaction between calcium ions and phosphate or sulfate. For example, dose at opposite ends of the tank, or allow sufficient time to mix between parts.

Of course more complicated automation is possible too. For example, this board could manage multiple reservoirs simultaneously, or sense EC and pH both in the reservoir and in returning solution from NFT channels, or manage fertilizer injectors for a drain-to-waste system. The large number of inputs and outputs is intended to provide flexibility to interface to almost any conceivable system's sensors and actuators, with the automated behavior determined by the software that commands this board.

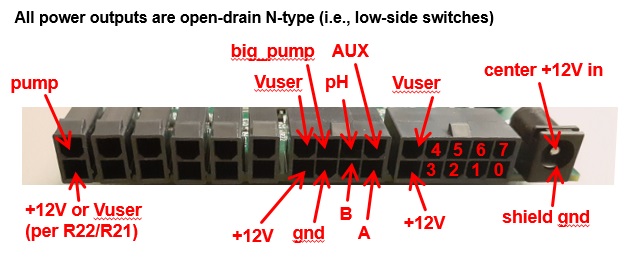

Input power is +12 V, which feeds the power outputs directly. It also feeds a buck converter that makes our +5V, and a buck converter that makes Vuser, arbitrarily adjustable with a trimpot. An LDO makes +3V3 from +5V, and all our logic runs from that.

The ESP32 is a module with integrated antenna. It would be better for the antenna tuning if the board outline had a cutout for that, but I preferred mechanical robustness over antenna range. The ESP32 drives two 8-bit serial-input, parallel-output shift registers, which function as GPIO expanders and gate drivers for the pump and solenoid power FETs. Max current for the solenoid outputs is determined by thermals due to I^2*Rdson. I haven't measured that temperature rise, but something around an amp should be quite safe. Max current for the pump outputs is determinated by the 2.2 ohm low-side current-sense resistor, and could be increased by decreasing that.

The dosing pump gates are driven directly by ESP32 PWM outputs. A series LC makes the negative-ground equivalent of a buck converter on those outputs, enabling us to drive the dosing pumps not with PWM but with a programmable DC voltage. This decreases radiated emissions, and provides something like a constant voltage output as long as the converter remains in continuous conduction.

The pump outputs return their ground current through a current-sense resistor, and an ESP32 ADC channel measures the voltage across that. This enables us to measure pump current. For example, if pump current is much higher when pumping water than when pumping air, this lets us measure the volume of water pumped out of a tray by measuring when the pump current drops. The current can also be used for health monitoring, to confirm the pump is actually connected and operating with expected load.

A pH electrode develops a voltage around 0 V at pH 7, plus or minus roughly 59 mV per pH unit at room temperature. Its output impedance may be many megohms, so we measure that voltage with an electrometer-type opamp, with femtoamp input current. To mitigate leakage resistance across our PCB (e.g., due to ionic contamination from flux residue), we surround the sensitive trace with a driven shield held at the same voltage as that sensitive node. I've seen no trouble due to leakage even without cleaning flux, though I live in a dry climate and it would be better to clean that.

Since the pH electrode voltage may be positive or negative and we don't have a negative supply, we connect its "ground" to a 1.2 V reference. This means that any electrical connection between our circuit ground and the solution being measured will result in an incorrect measurement, though the shunt regulator that generates that rail can survive a short to ground without damage. The shield of the BNC connectors is 1.2 V, not ground. As long as the board is powered from an isolated power supply (for example, a typical mains-operated power brick), no further attention should be required; but take care not to de-isolate it, for example by attaching board ground to any metal that touches the solution.

Even with DC isolation, a significant 60 Hz (or 50 Hz) component may be present on the pH probe voltage. If this saturates the front-end amplifier, then no subsequent low-pass could recover the correct DC voltage. We address this with a capacitor across the pH probe. The resulting low-pass time constant is poorly-controlled, since it's a function of the probe output resistance. That's fine in practice though, since pH shouldn't change significantly over any timescale faster than minutes.

We pull both sides of the EC electrode up to +3V3 through 1k resistors, so they both rest at +3V3 with respect to circuit ground, 0 V differential. To measure EC, we pull one side to ground through an n-FET, and then measure the voltage of the other, making a voltage divider between the known 1k and the unknown resistance under test. We then repeat the process for the other side, restoring zero DC voltage across the electrode to avoid polarization. The EC electrode is also AC-coupled through 22 uF ceramic capacitors, guaranteeing zero DC voltage even if the software misbehaves or the resistors don't perfectly match and, more importantly, presenting high imepedance at DC so the EC electrode doesn't short out a pH electrode immersed in the same sample cup. Assuming EC around 2 mS/cm and cell constant around 1 cm, we get a high-pass time constant around 4 ms, which is much slower than our measurement period of ~500 us. Electrolytic capacitors can't be used for that AC-coupling, since the leakage current is too high.

A similar approach may be used to measure EC with almost any microcontroller and no additional components beyond the reference resistors and AC-coupling capacitors, by configuring that microcontroller's I/O pin as an output low to ground it. I chose to use the external FETs here because I'd run out of microcontroller pins, and because the lower and more consistent Rdson improves accuracy at high EC (since that appears in series with the resistance under test).

None whatsoever. Use this only behind a firewall (like a typical residential NAT router), on a network with trusted users only. If you need remote access, expose it through a properly-secured jump box or VPN, not directly.

THERE IS NO WARRANTY FOR THIS SOFTWARE OR HARDWARE, TO THE EXTENT PERMITTED BY APPLICABLE LAW. WE PROVIDE THE SOFTWARE OR HARDWARE "AS IS" WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESSED OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

DO NOT USE THIS SOFTWARE OR HARDWARE IN SITUATIONS WHERE ITS FAILURE COULD RESULT IN DANGER TO HUMAN LIFE. For example, don't dose concentrated acid and rely on correct operation of this board to safely dilute it--instead dose a higher volume of less concentrated acid, or use safer chemistry (monopotassium phosphate, etc.). Also think carefully about the risk of overflowing water, dead plants or fish, and other damage, and don't rely on software to prevent it.

The firmware is licensed under the GPLv3 or later. The legal framework for open hardware is poorly-established, but you may build and sell, give away, or otherwise transfer any number of hydromisc boards, provided that:

-

any software loaded on the board is free software (as defined by any OSI-approved license), and that software is not intended primarily as a bootloader or other tool to load, program, or otherwise enable use of non-free software; and

-

you do not falsely claim ownership of the design, or any affiliation with this project beyond your permission to build boards per above.

For now, this project is useful only to people with sufficient programming skill to build and load the firmware, and to use the http interface above. For future, it would be nice to:

-

Integrate with existing control software (Mycodo, home automation packages, etc.)

-

And/or, add logic on the ESP32 itself for timed irrigations and closed-loop dosing based on measured pH and EC, to allow this board to work standalone with no need for the network except for initial configuration. Firmware to log and graph (as a web page) sensors over time would also be helpful in standalone use.

-

Add a friendly mode to configure Wi-Fi settings, since those currently must be compiled in. For example, if some combination of pins is jumpered at startup, appear as a Wi-Fi access point to which the user can connect and provide the real access point name and password. Then save those credentials in flash, and use them after reset.

-

Clean up how concurrency is managed in the firmware. The present code seems to work, but it's a lazy hack that's hard to analyze for races.

I might eventually do some of that work myself, but I have limited time and welcome other contributors. Please feel free to use GitHub issues to discuss potential new features or anything else.