-

Notifications

You must be signed in to change notification settings - Fork 2

New issue

Have a question about this project? Sign up for a free GitHub account to open an issue and contact its maintainers and the community.

By clicking “Sign up for GitHub”, you agree to our terms of service and privacy statement. We’ll occasionally send you account related emails.

Already on GitHub? Sign in to your account

Design review #1

Comments

|

Hmmm, fuses are to prevent fire. Typically located at the source so you remove the source of energy. I typically don't size fuse to protect the devices, I typically size to protect the wires or things that can catch fire. I also don't like fuses, it's hard to properly size them for I2T issues. In this case the pulsing will cause high amps for short periods of time, so I2T issues are elevated. I tend to think the fuse should be closer to the panel, if it should be there at all. Some times I use a fuse as it's easier to repair then a burnt copper trace. L1 includes Digikey part number 495-5076-ND. The schematic properties includes part numbers for either JLC or Digikey. I was planning for 12AWG wire, and I used this prediction tool to predict 6 wraps. https://coil32.net/online-calculators/ferrite-torroid-calculator.html I think 10AWG might also fit, but insulation thickness is likely a concern. Of course if you need more windings, then it may not work either. I recently found the below. Any thoughts about cramming 50A through a SO8 package? I'm concerned about I2R on the traces. I included J33 and J34 as an option to add a copper wire to help keep the current off the PCB layers. I was not able to make meaningful predictions of heat generated by Q1, Q2 or Q3. Rds generated watts was not helpful, the real heat will be the transient conditions. 2.6mOhm * 35A^2 = 3W. I don't much about what the losses will be during the switching. How many watts do we think we need to get out of these? Q3 also wants more electrical insulation from the heatsink. Which isn't going to help the situation. I also should pick a fan and some how include that in the 3D printed case. If I had some kind of prediction of the watts, or some kind of empirical data to work from, then I could make a better thermal prediction. Q1 and Q2 secretly conduct a bunch of the electrical energy via the screw on the tab. I expect the copper layers are not large enough, but copper with tabs bolted together should be good. Looks like the C7 change will either be a huge layout change or I might just bolt the cap to heat sink. That's going to be a bit of work to change. I hear you about the current loops. I'm expecting this to be around 20kHz. Is that a proper frequency to be expecting? I really don't know the low core frequency to be considering. I'm USA eastern standard time. If a phone call helps perhaps we can phone. |

|

This is a good layout reference https://www.maximintegrated.com/en/design/technical-documents/tutorials/5/5450.html specifically the simulations showing you that at about 1KHz the ground plane currents start to follow the matching trace. |

|

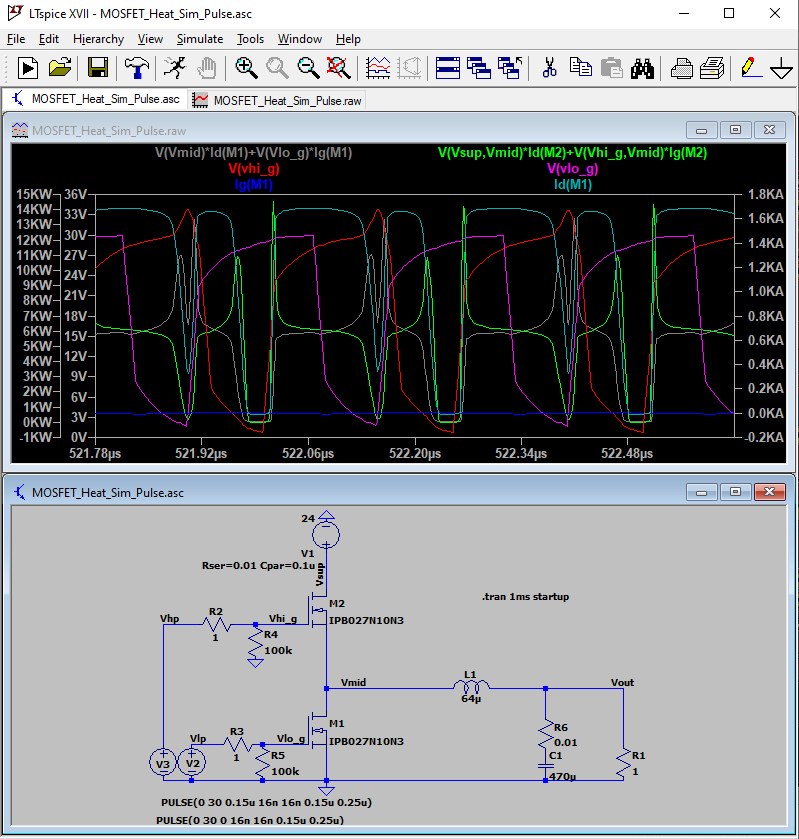

I've tried several simulations to predict the heat generated by Q1, Q2, and Q3. So far this is the best I've managed. It uses a similar but different MOSFET and actually simulates without crashing. I see PSPICE for TI offers the actual MOSFET being used. However it appears the spice model has a typo in the .ENDS part of the SPICE model, as it errors out and does not compile. In the LTSpice I'm learning how to create an equation to multiple the instantaneous V * A for the MOSFET, then I can plot that to see the instantaneous watts. Perhaps worth nothing, this simulation suggests the 100ohm series gate resistor is limiting pulse. I'm not sure if that would be the same in the real world or not. But it might warrant a close review. |

…OSFET's. Looks like I'll have to use the file based voltage control instead of the generic pulse power supplies. \#1

|

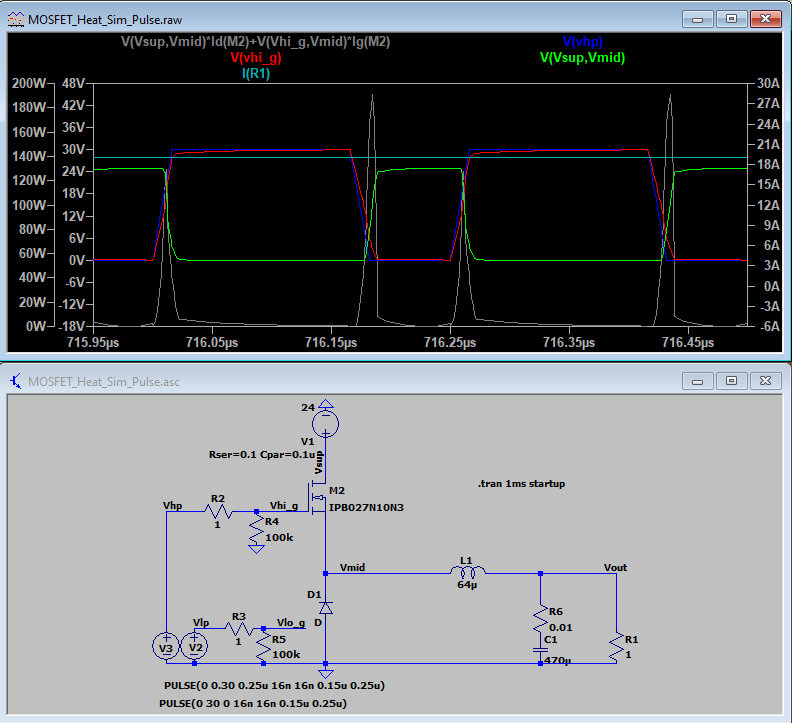

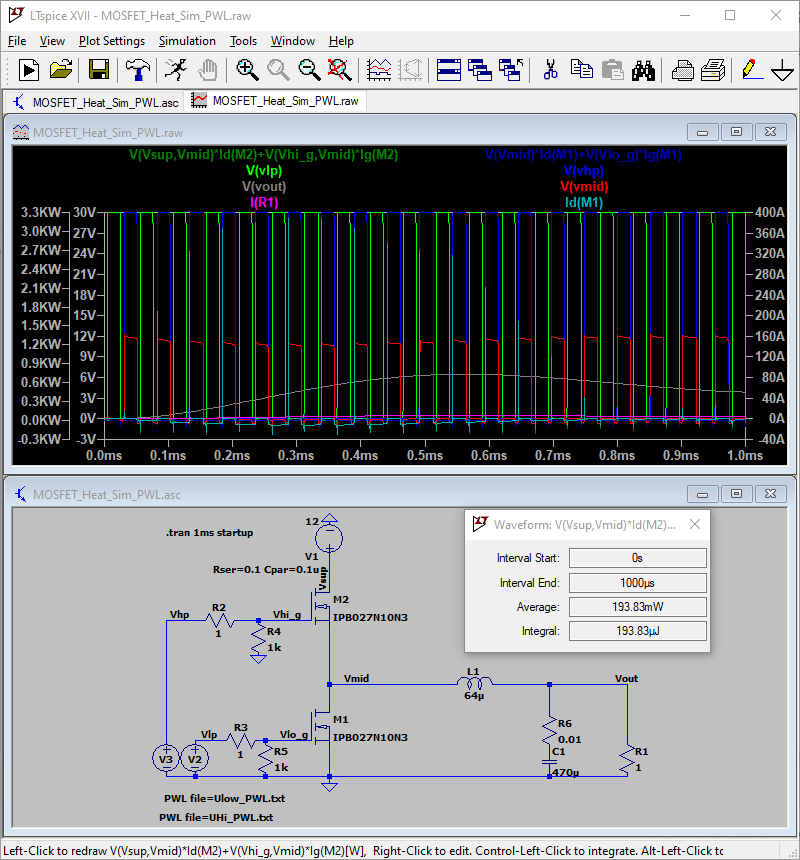

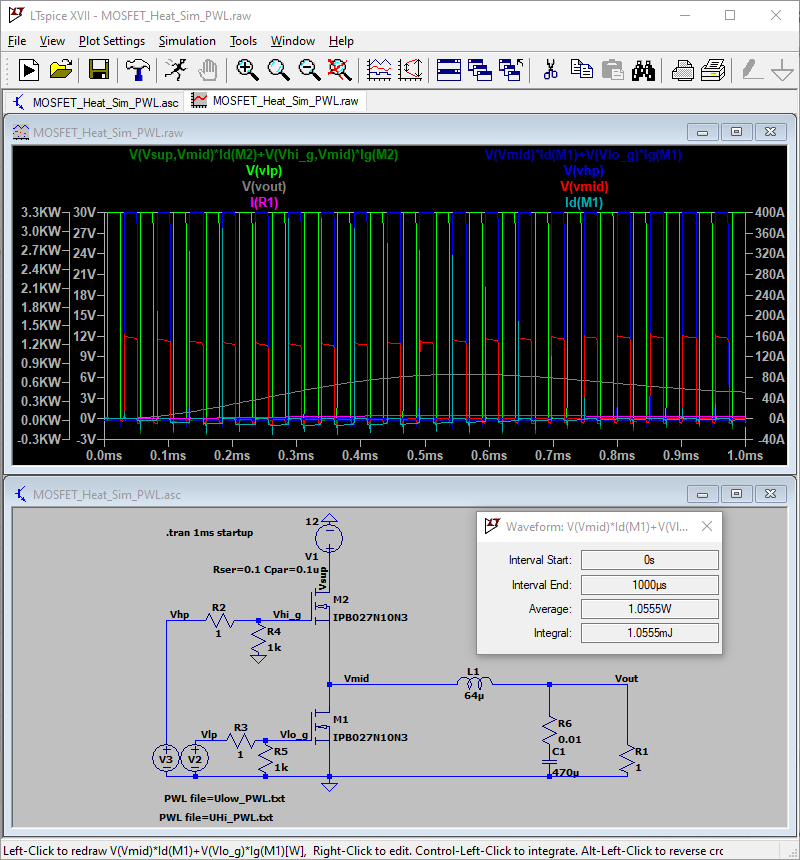

I wonder if I can get LTSpice to integrate so I can make a prediction of the heat generated by the MOSFET. In the below simulation, with only the high side drive, I see these large but short spikes of heat. Like 300W during the transition stage, and basically 0W any other time. I really need to know the area under the curve to know what kind of energy the heat sink needs to deal with. |

|

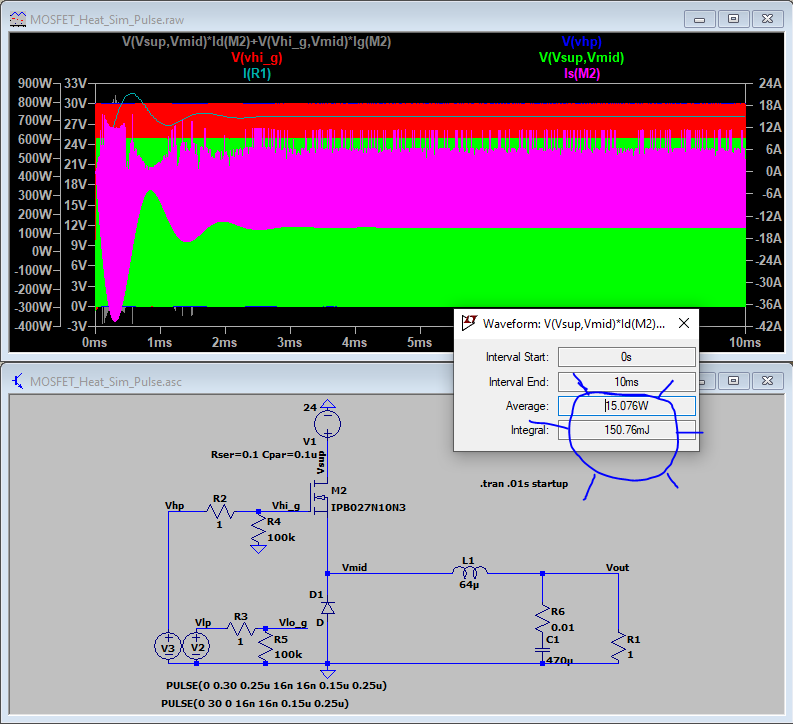

In LTSpice after you run the simulation, you can add probes. If you hit the alt button, then select a component, it will graph the instantaneous watts for that component. Then if you hit crtl and click the text of that trace, it will integrate what ever is in the graph. I did this for just the high side MOSFET, of similar Rds while it was running at about 19 amps. For 10mS it averaged at 15W. |

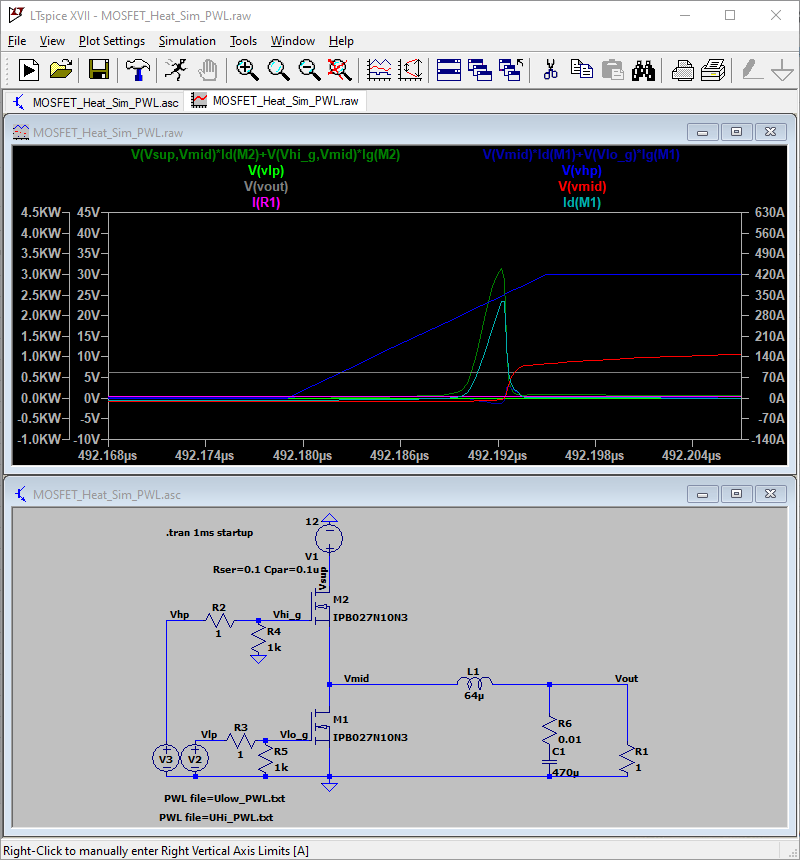

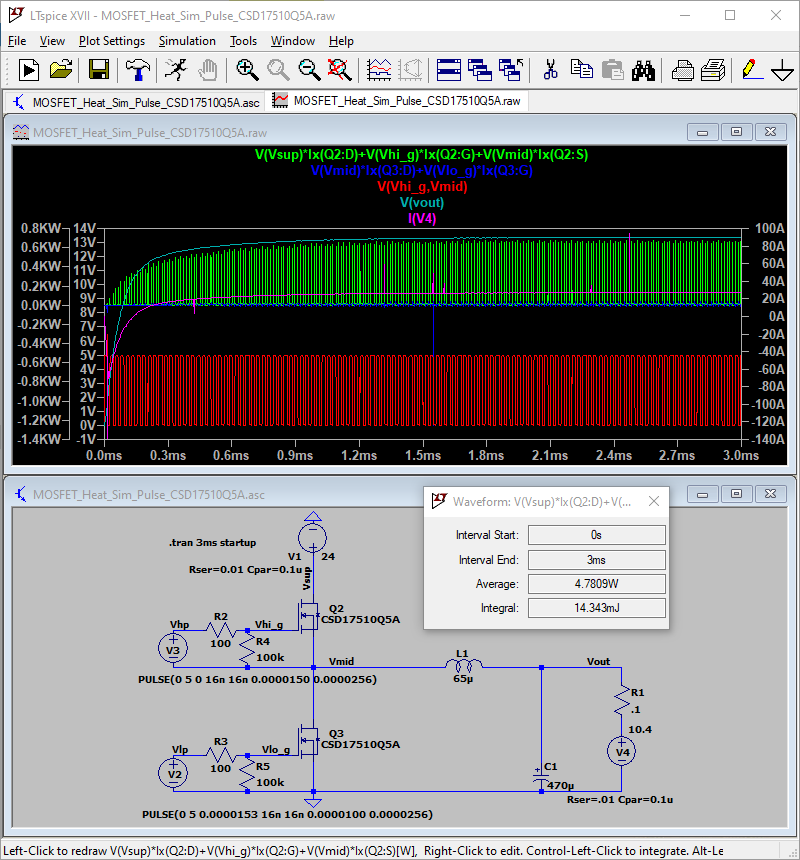

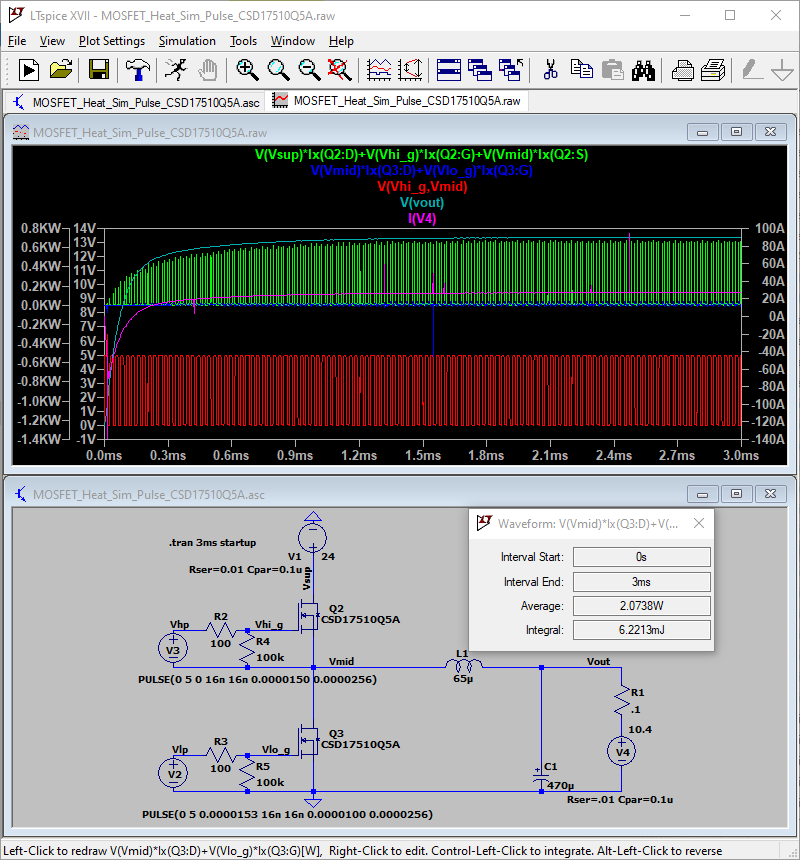

The simulation has finally produced some results. I obtained the SPICE for the CSD17510Q5A from PSPICE for TI, by exporting the file, then importing it into LTSpice. This seems to be producing a fairly decent watts generated prediction. It's not perfect, I couldn't get the simulation to always work, for some reason it would lock up if V1 went above about 31V, then it would start working again if it was at around 48V. I'm assuming that's some kind of limit embedded in the SPICE file. However if it was at around 48V, the MOSFET's claimed to dissipate KW instead of W, As well I had to be cautious when V4 was around 15V, as it would commonly back flow L1. With these limitations in mind, and with some very finely tuned on and off times, I think I have a fairly good prediction of the watts that Q2 and Q3 generate. I believe Q1 is just on or off, so the RDS predictions for that should be fine. So we'll call that 35A^2 * 3mOhm = 3.7W. In the below, Q2 claims 27A output and less then 5W. Then Q3 in this same simulation is 2W. I see many items which need to be very closely monitored. For example the V2 the parameter which is 0.0000153 needs to be between about 0.0000151 to 0.0000155. If it's outside that range, then the MOSFET dissipates KW instead of W. For now I'll plan for Q2 = 5W and Q3 = 2W. So I'll call it about 10W total. The MOSFET max junction temp is 175C, and it has 0.5C/W from junction to heatsink. The HeatSink has a about 6C/W rise with a small fan, but could be 2.5C/W with a more powerful fan. So rise is about 10W * (0.5C/W + 6C/W) = 65C rise. So the ambient could be as high as 110C before it hits the limit of the MOSFET junction. The ambient is more likely to be below 40C, so the rise could get up to 105C. I tend to start getting concerned above 85C, as FR4 often starts to fatigue around 85C. As well a 3D printed case is probably only good to around 45C to 55C. I think the heatsink in the BOM should be OK, but I would prefer if it was larger. I'd prefer it if worked better with out a fan. |

During my simulations efforts I found the below. It's only 17.2A, but it's a purchasable option, and I don't have to design it's internals, they simply tell me it can handle 17.2A so I assume the saturation is OK up to 17.2A. |

|

I have published a revised design. Thank you for your feedback. If you feel so inclined a second review would be great. Here are some key notes of interest. |

|

Hi @jharvey, Looks fairly good. I do have a few comments:

-Regards, |

|

L1 part saturation: TDK 495-5076 allows 500mT at 25dgrC vor 410 at 100dgrC (Material N27): https://www.tdk-electronics.tdk.com/download/528850/3a7f957d754f899aec42cd946598c5c4/pdf-n27.pdf |

Hi, I am no electronics guru, but here are my suggestions.

Schematic:

Layout:

The text was updated successfully, but these errors were encountered: