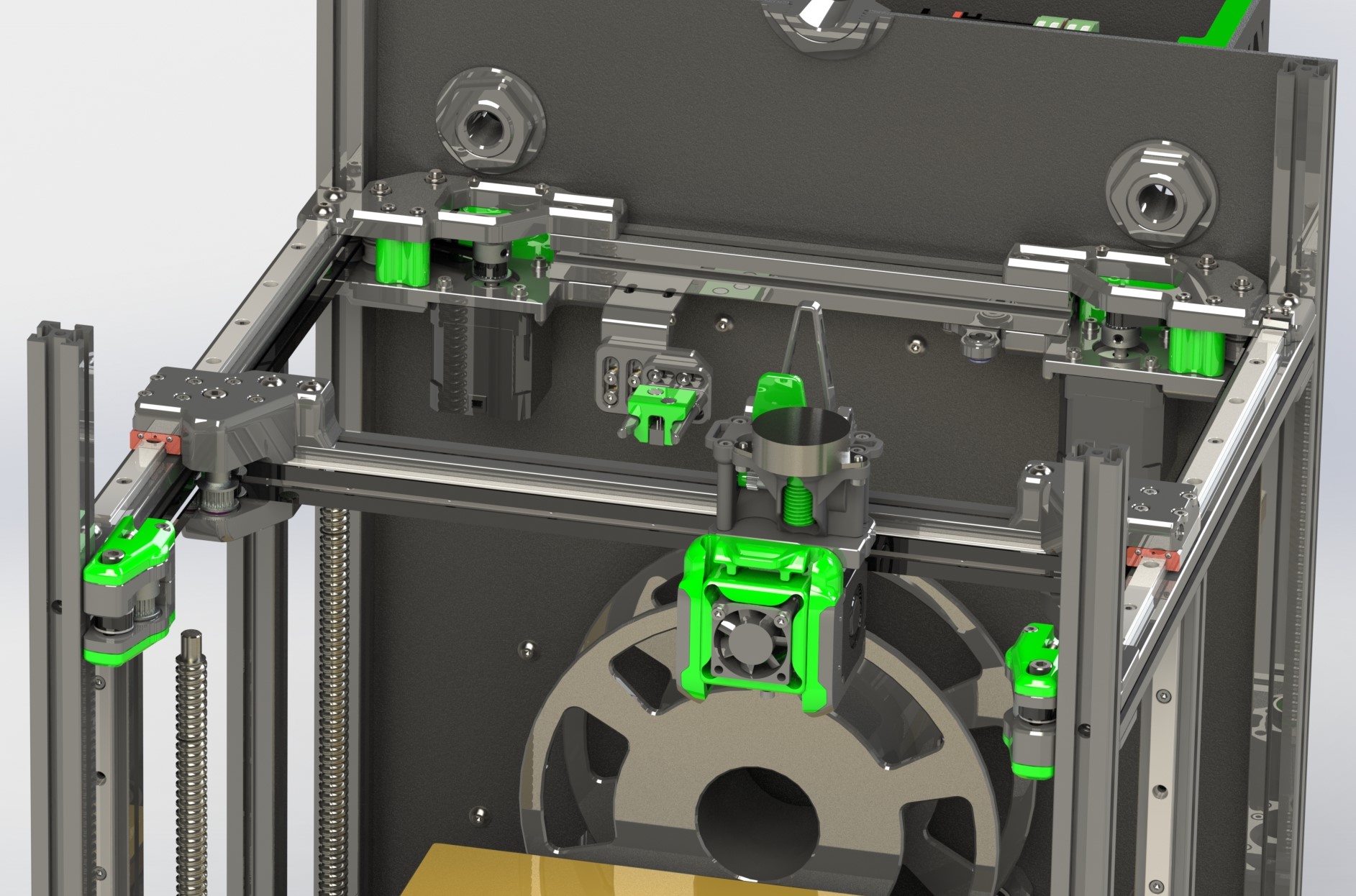

Project Denali is a CoreXY, Moving Bed, Medium Size, Direct Drive, FDM Printer

The main goal was to reduce complexity, while providing a fast reliable and ultimately simpler printer.

Our discord server can be found here: https://discord.gg/MzTR3zE

BOM/Sourcing Guide for a 250x250x200 Build can be found here: https://docs.google.com/spreadsheets/d/1O3eyVuQ6M4F03MJSDs4Z71_XyNjXL5HFTZr1jsaAtRc/edit?usp=sharing Frame Calculator: https://docs.google.com/spreadsheets/d/17bdA1itJfFXpg5xXoUhM7PC9FFtjTBpXj1FjgBG_8xA/edit?usp=sharing

This printer features the following:

- Fully Enclosed Design

- Supported Build Volumes of ~200x200x200 to ~350x350x300

- Single Direct Drive Fed Extruder (V6, Dragon and Mosquito Hotends Supported)

- CoreXY Belt Path

- Moving Bed with Tri-Stepper Leveling and Squaring

- MGN9H Rail/Carriage Combo on all Axis

- Dual Rail X Axis for Increased Stability

- 0.9 Deg XY Steppers, 1.8 Deg Z and E Steppers

- 6mm Belts on XY, 1204 Ballscrews on Z

- Minimal Printed Parts

- Designed to be Printed with ABS

- 32 bit controller standard, Dual Bigtree Tech SKRs + TMC2209 Drivers or Single FYSETC S6 + TMC2209 Drivers

- 24V Power Standard

- AC Mains Bed with Thermal Cutoff Fusing

- Powered by Klipper: https://github.com/KevinOConnor/klipper/