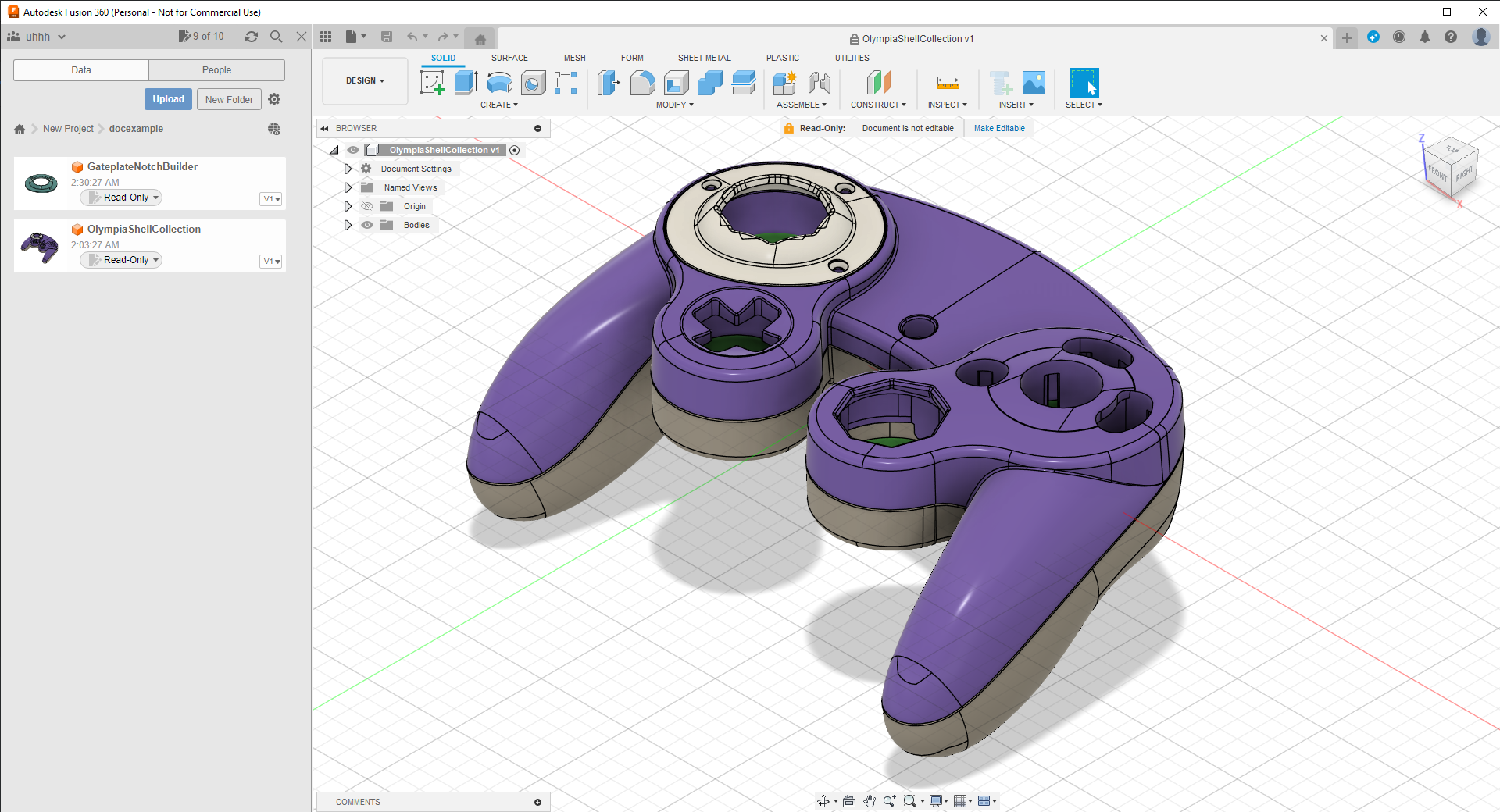

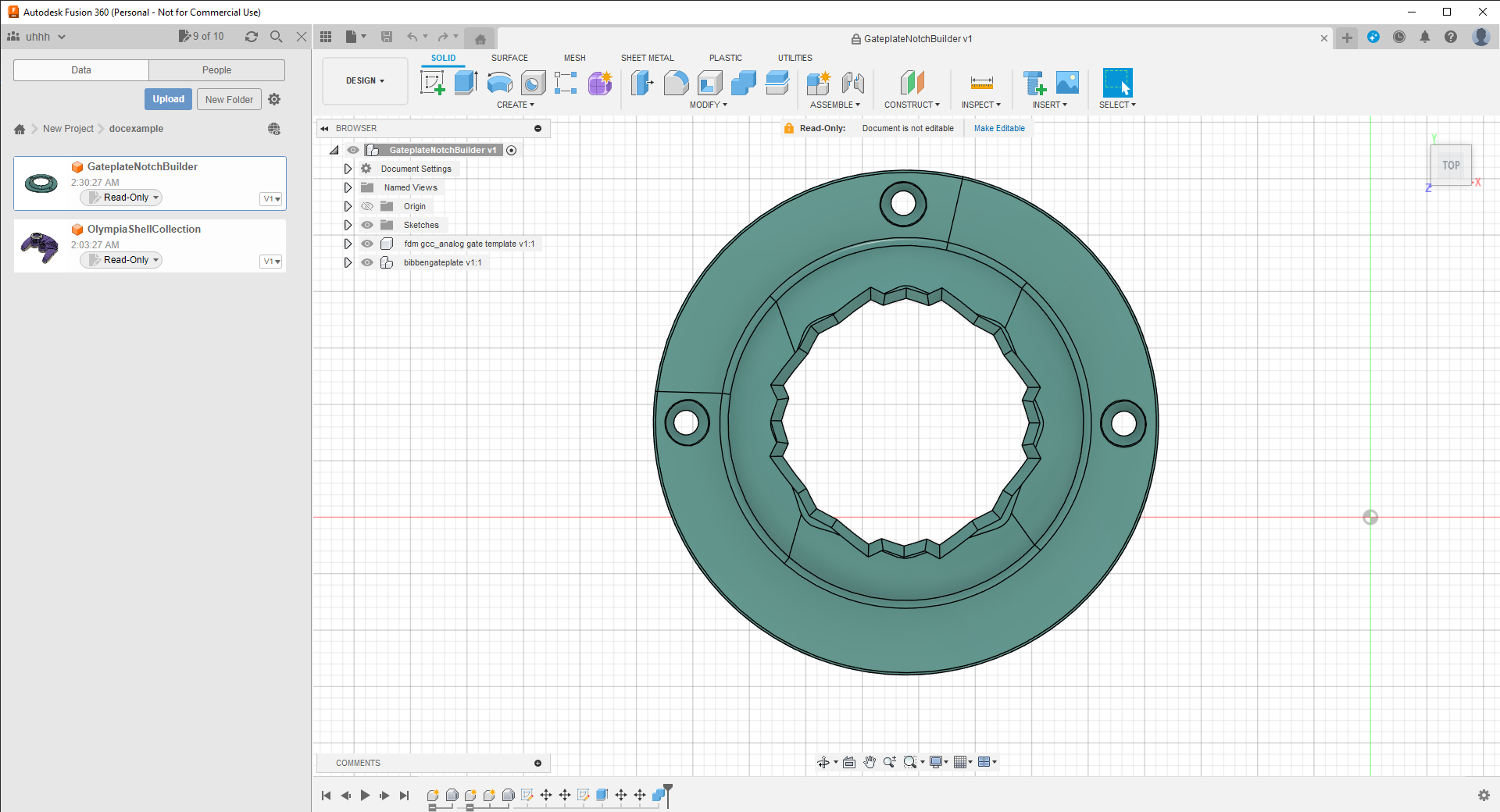

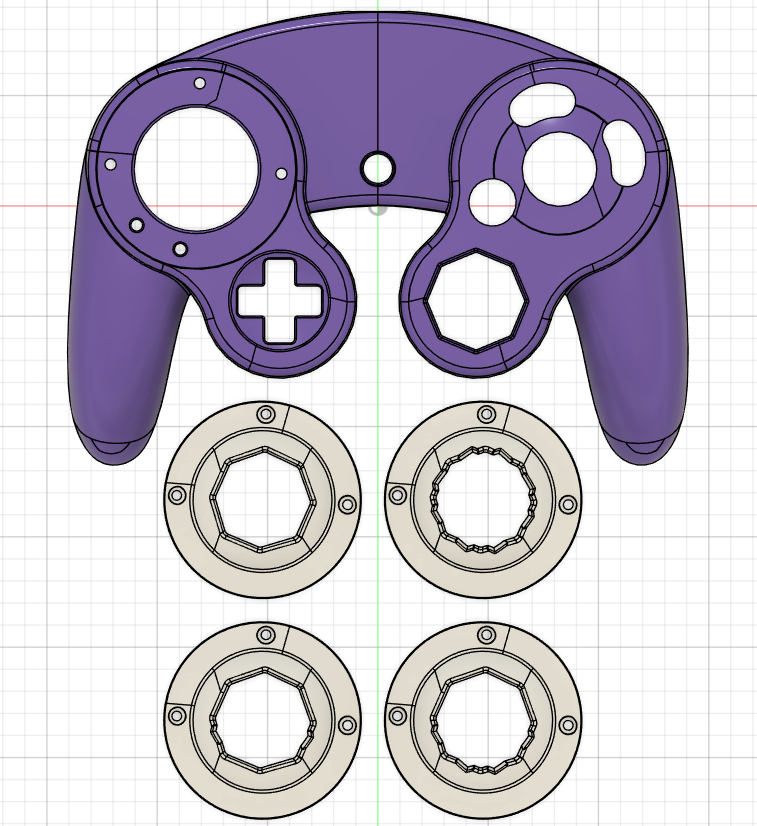

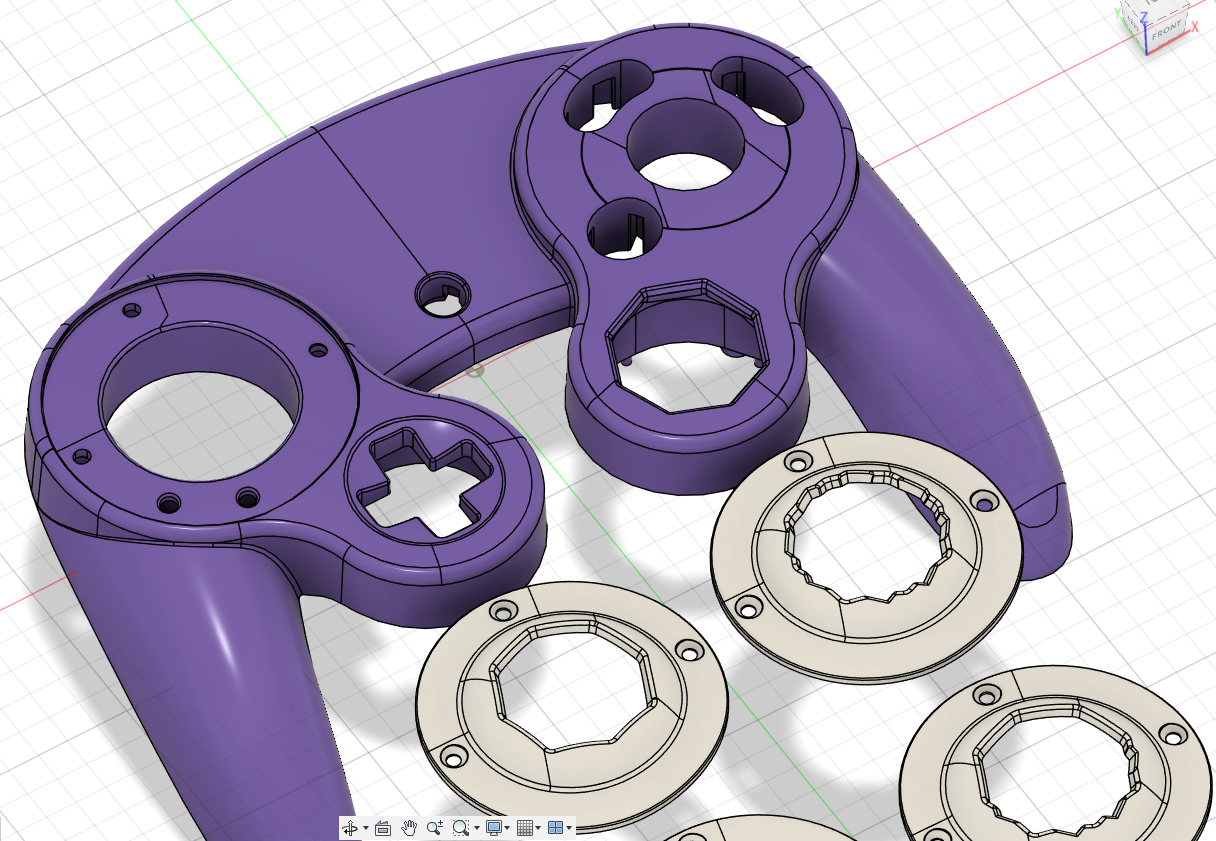

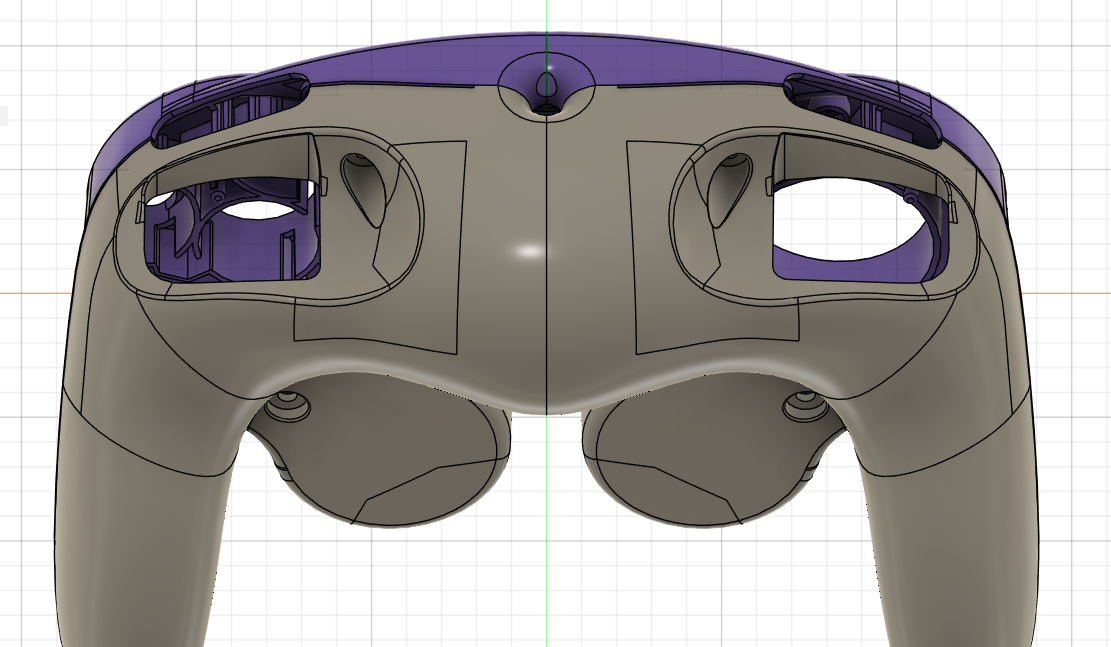

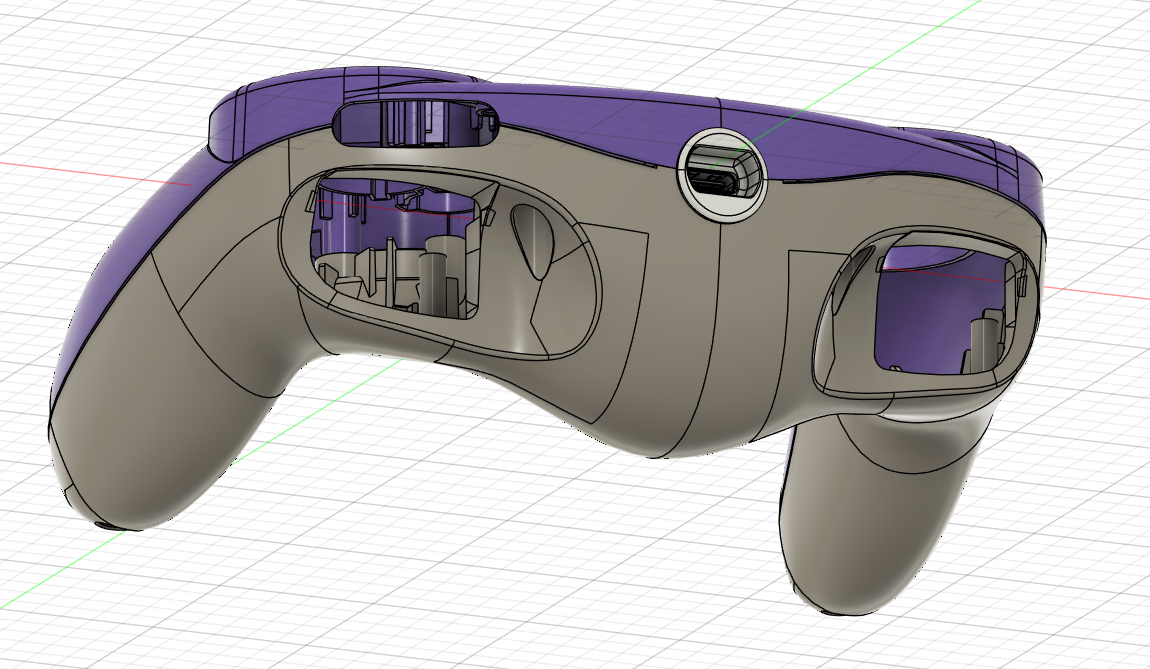

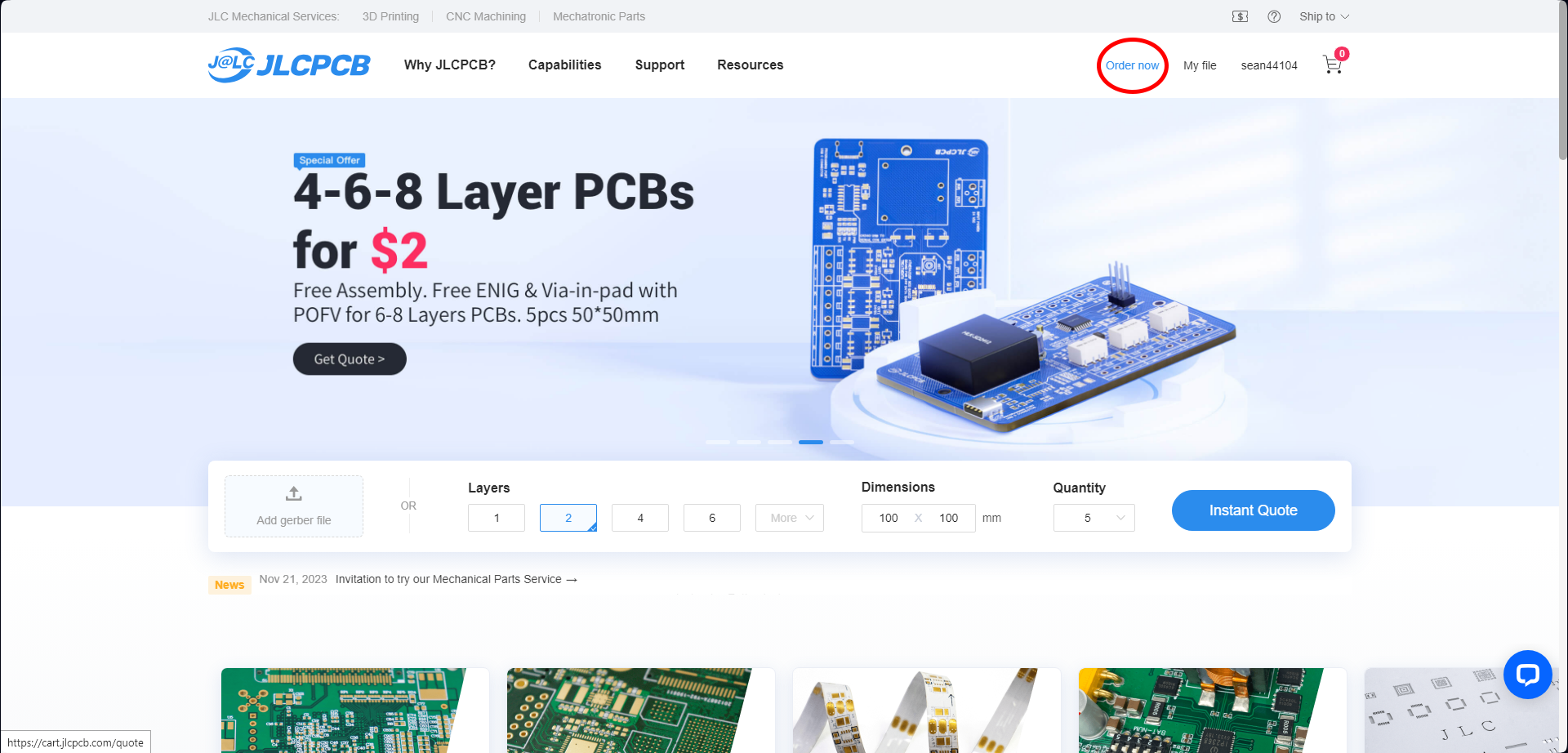

This is a collection of custom gamecube controller files made to be resin printed. These files feature a variety of mods. Removable Gates, Digitally Notched Gateplates, Double Z, USB-C, Metal Threaded Shell Inserts, and a Fully Parametric Custom Notch Builder Tool!

The release contains F3D files with the STEP files for each part as well as the Notch Builder. The V1 release includes a guide to using the Notch Builder and a guide on how to properly export files from Fusion360. The V2 release includes individual high resolution STLS that are print ready!

The main branch contains individual STL files for each part in v1 and v2, ready to be printed! (for those who dont have fusion360)

Here are some product links and guides!

Gateplate Screws: https://www.mcmaster.com/90236a103/

Gateplate Hex Nut Inserts: https://www.mcmaster.com/90592A075/

Video Guide On How To Install The Hex Nuts Into The Front Shell: https://youtu.be/vxjiae2Oz9I?si=B8-4NFnGVl_ovJBW

Video Showcase On Shell Material Fit: https://youtu.be/kKp5rs-HsGk

Bonding the hex nuts to the front shell allows you to take the gateplates off and put them on without ever opening your controller. Follow the guide. I personally use resin to do this, but glue would probably also work very well. Try to use a runny, liquid glue that will really seep into the hex nut channel. Make sure the screws are inside the nuts when you put the adhesive in so that it does not go inside the nut and make it unusable.

Parametric Notch Builder Tool by Bibben https://github.com/B1bben

PhoZL and OlyU boards can be found here: https://github.com/sean44104

USB-C plug provided by Rana Labs https://twitter.com/rana_labs_/status/1646009376925261824

This design is based on, and uses the full oem gcc step file made by GearHawkStudios.

Scroll to the bottom of the readme for an ordering guide and information on each JLC material (WIP) :D

NOTE: Here is a list of changes and improvements that were made for RGGCCv2.0:

-

A complete redesign for the Metal Threads Mod. It should be better, but I have not tested the design yet. Print this at your own risk and let me know how it goes!

-

The button wells have been slightly tightened. Now, the wells are much closer to OEM size. They should work great and the buttons should rattle a bit less! The button press feel should also be a bit more consistent.

-

The USB-C hole plug (BjartPlug) has been redesigned and expanded to be 15mm wide. Now, all USB-C cables should fit inside! I encourage people to redesign this part to add cool features, like perhaps a screw-in locking mechanism!

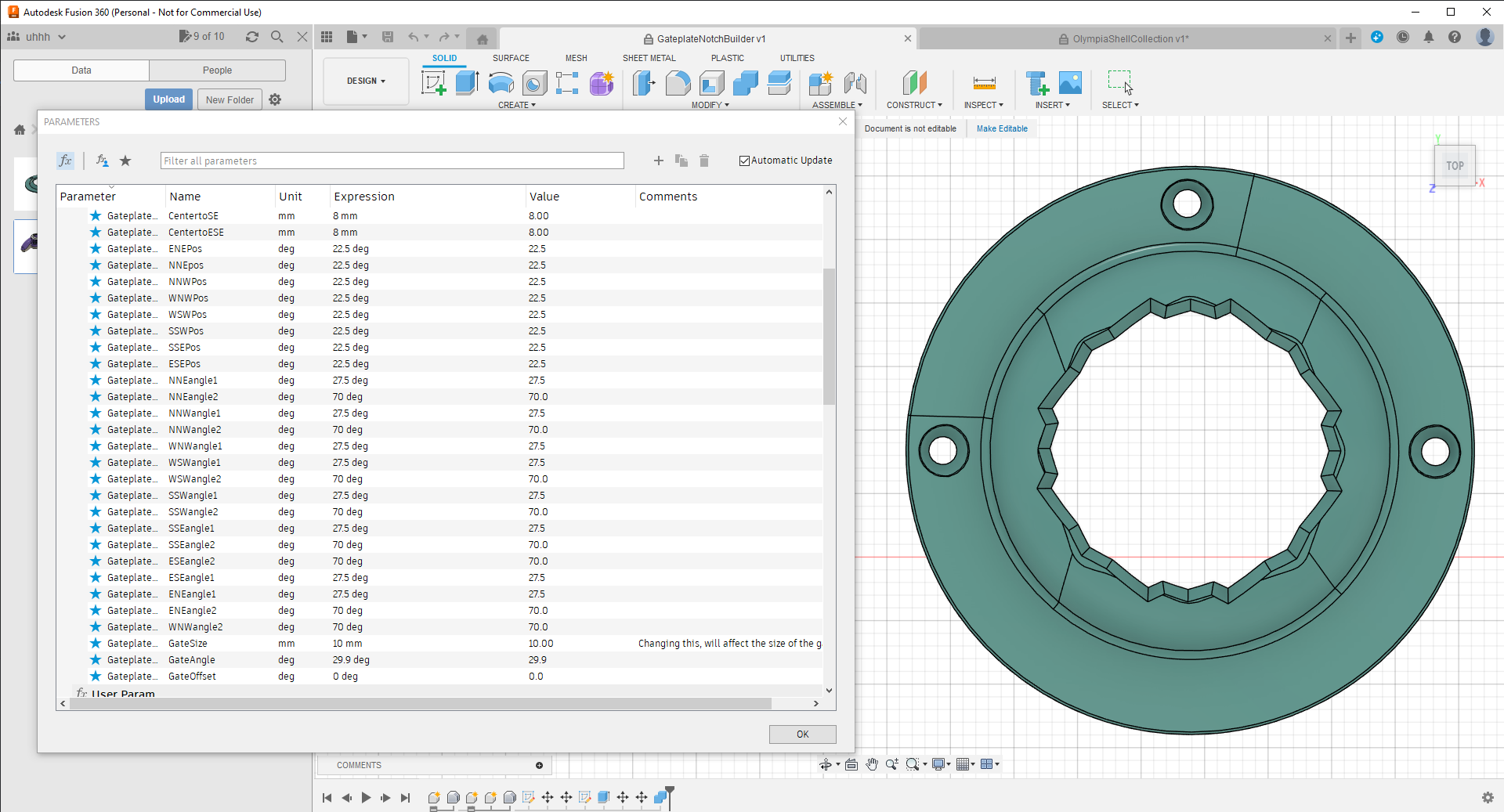

Go to https://jlcpcb.com and click on "Order now" (make sure to sign up and create an account!)

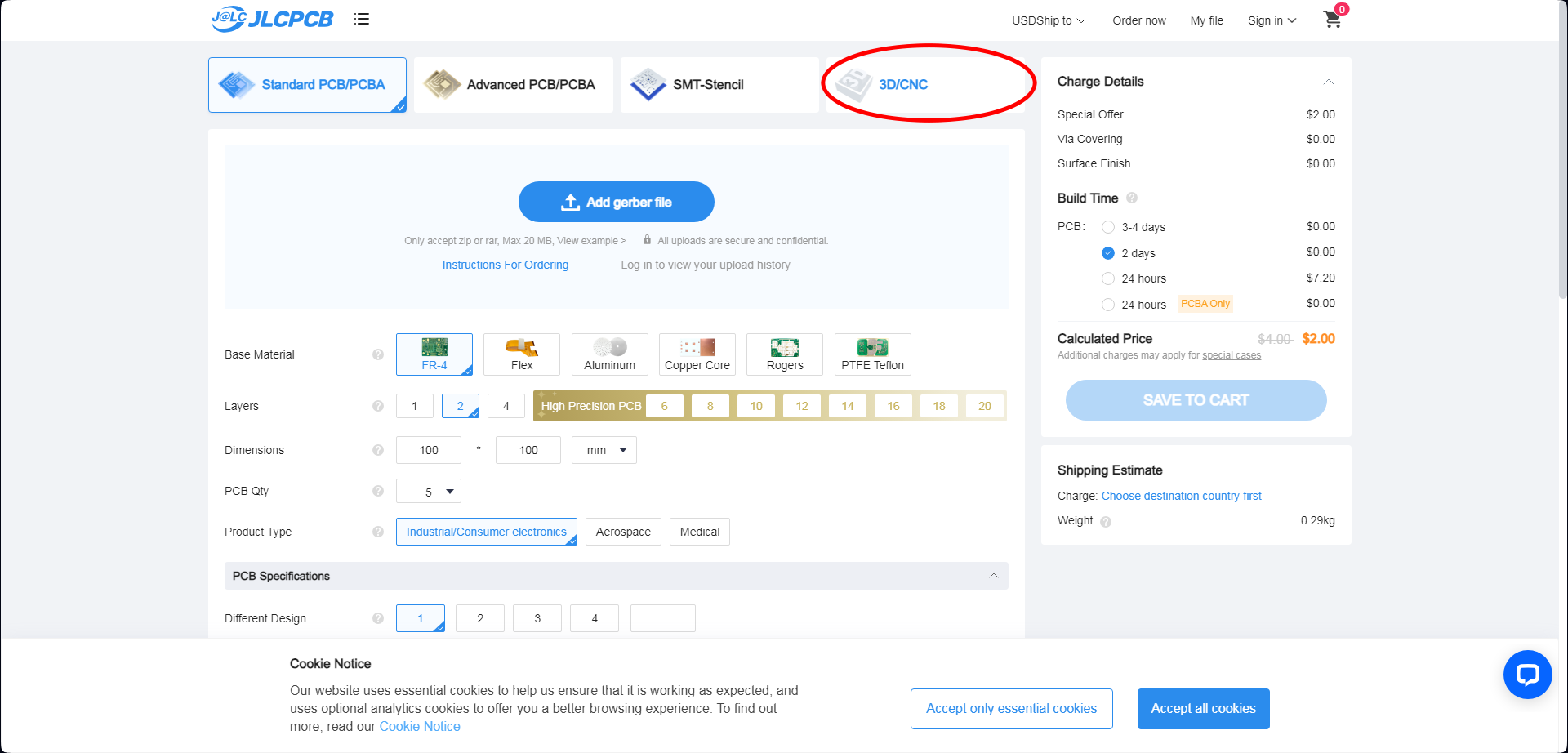

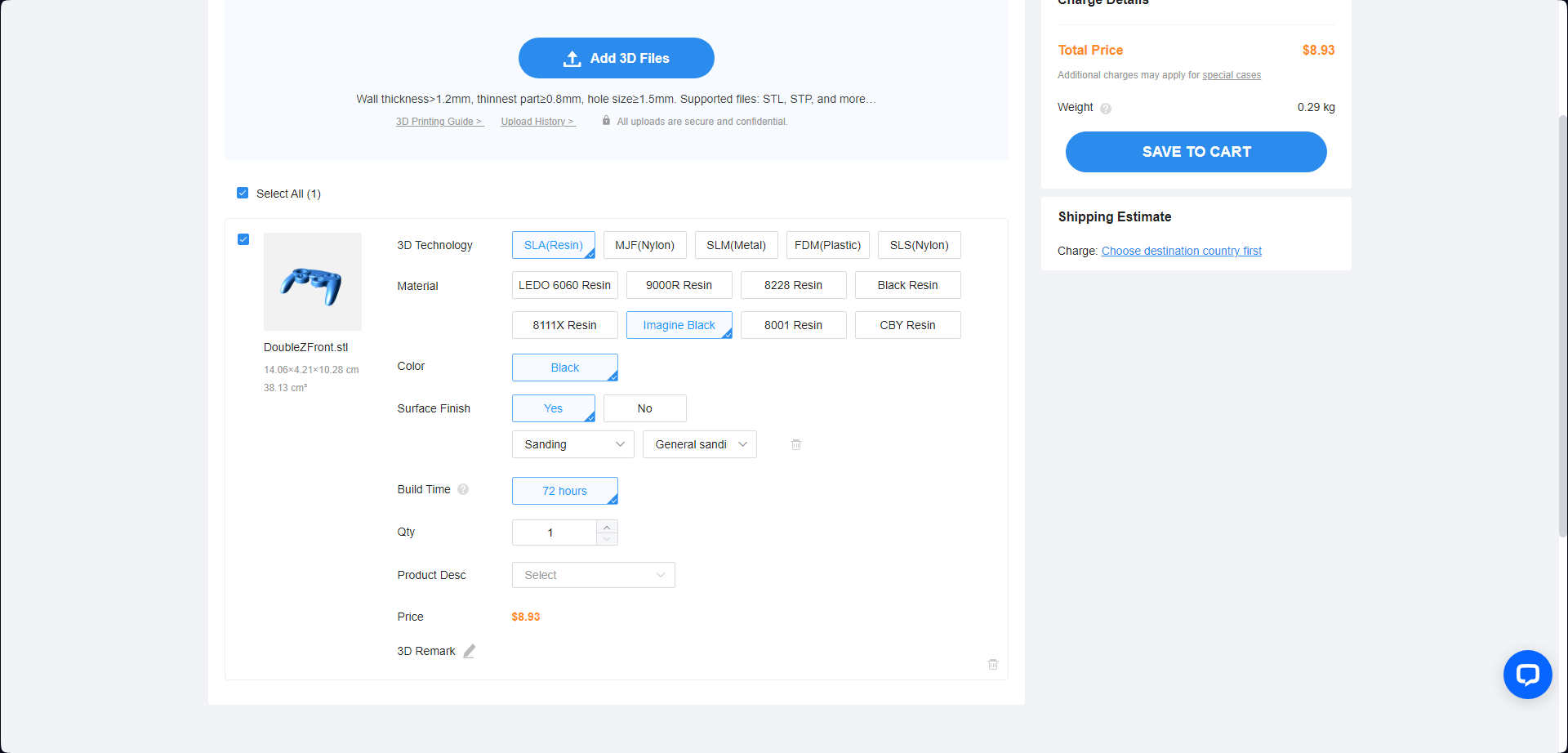

Go to "3D/CNC" and then drag and drop your STLs into the "Add 3D Files" box of the "3D Printing" section

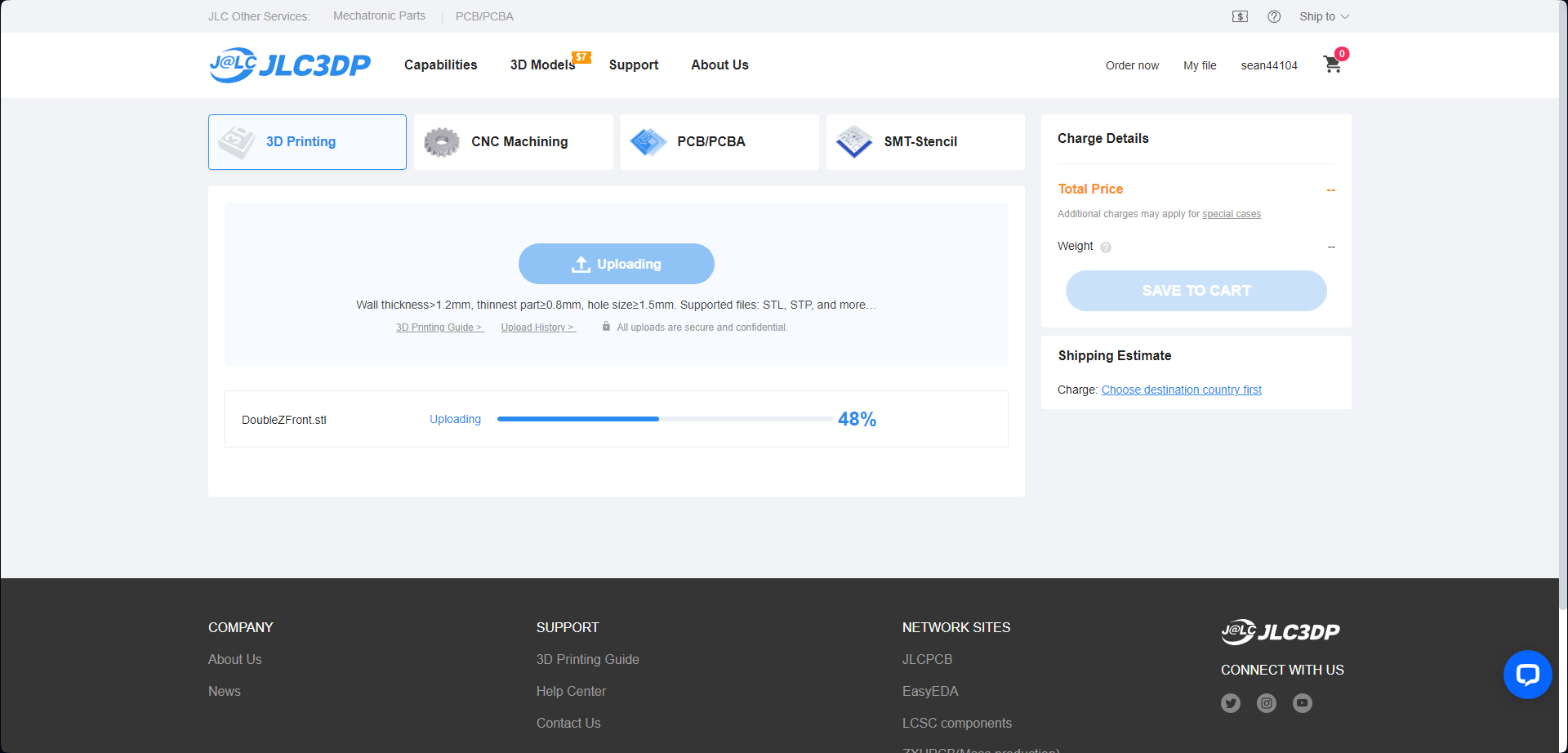

You can do multiple files at once! (Up to 10)

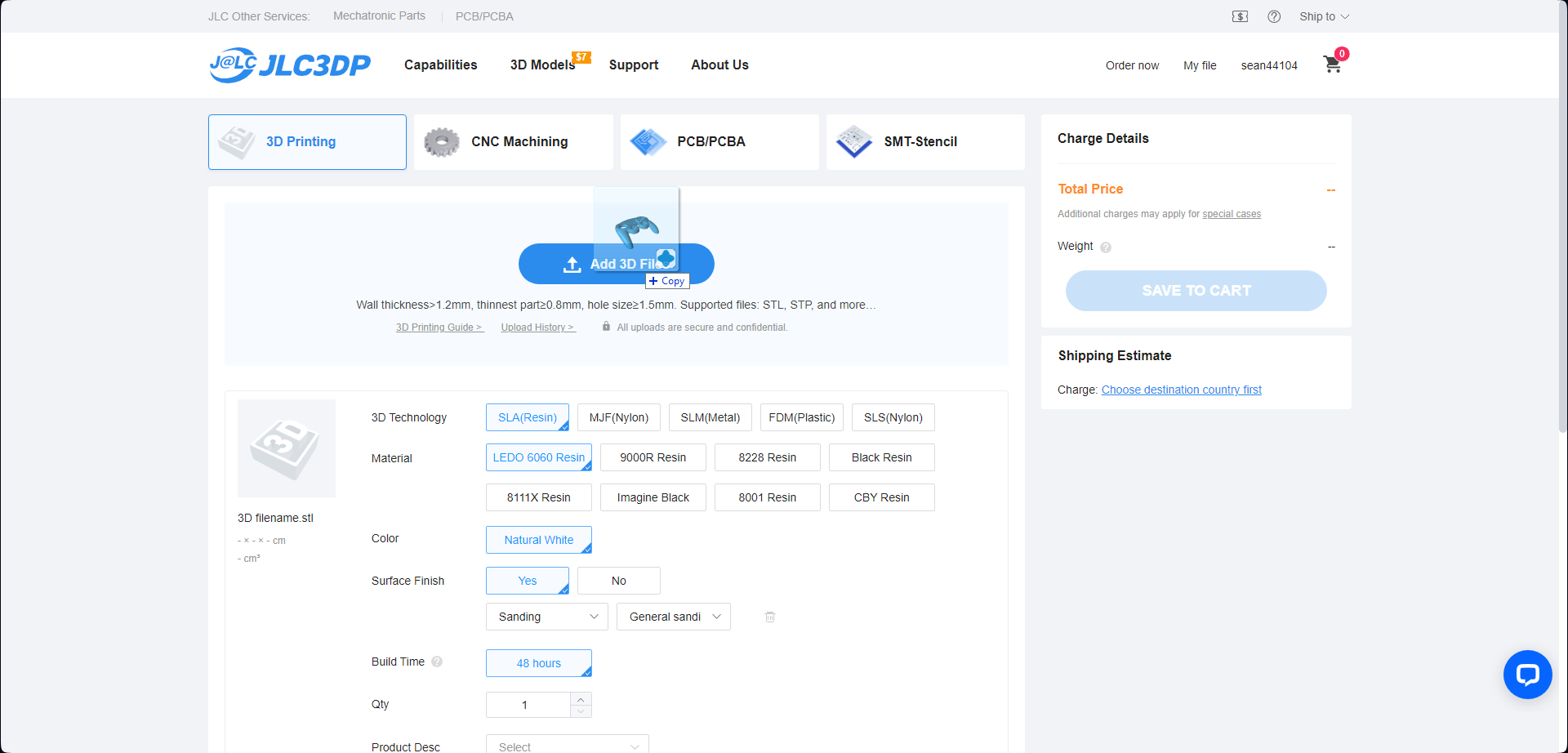

Once your files are finished uploading, select the type of 3D Technology and Material you want

My personal favorite for the shells currently is SLA(Resin) and Imagine Black with the default surface finish (sanding, general sanding)

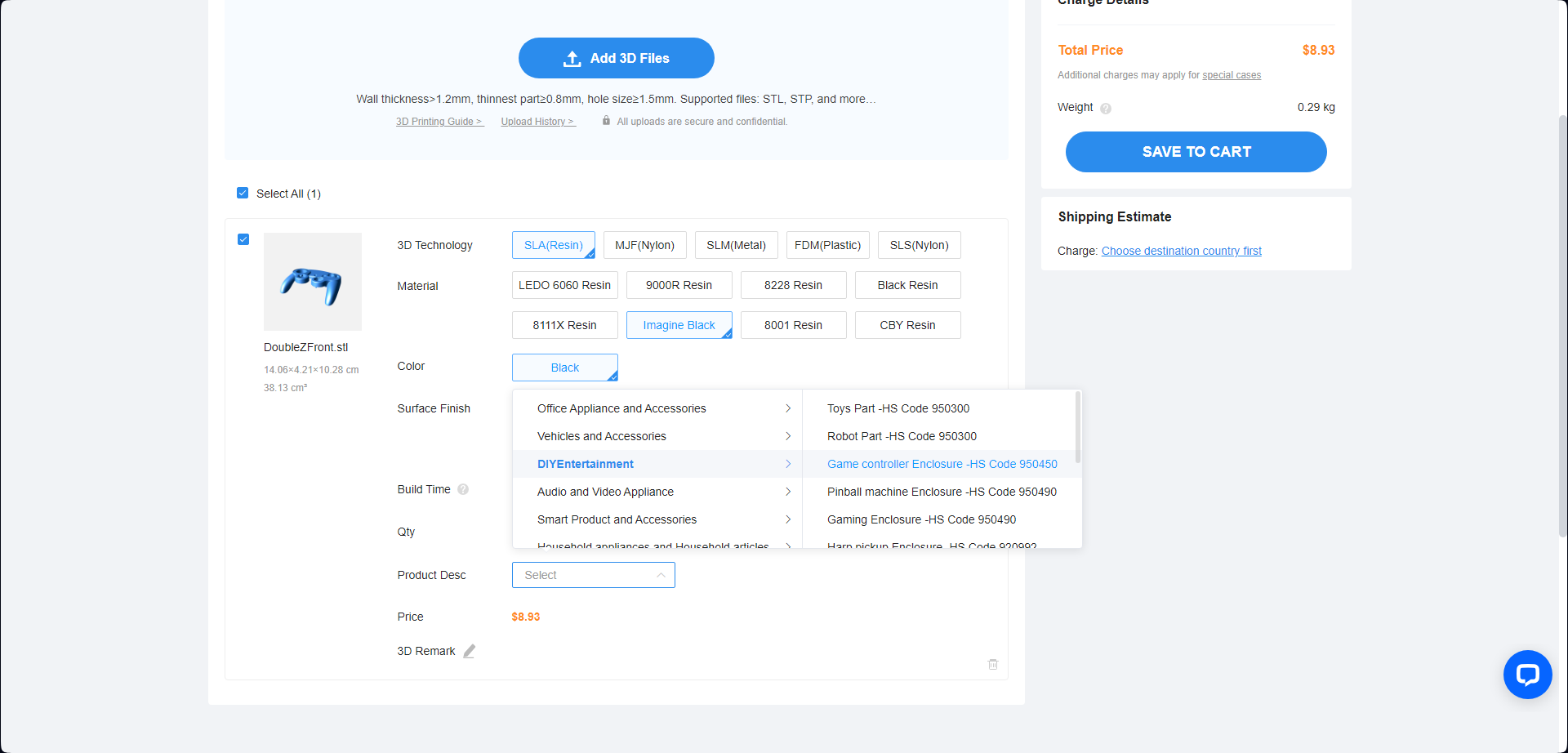

For "Product Desc" select "DIYEntertainment" and then "Game controller Enclosure"

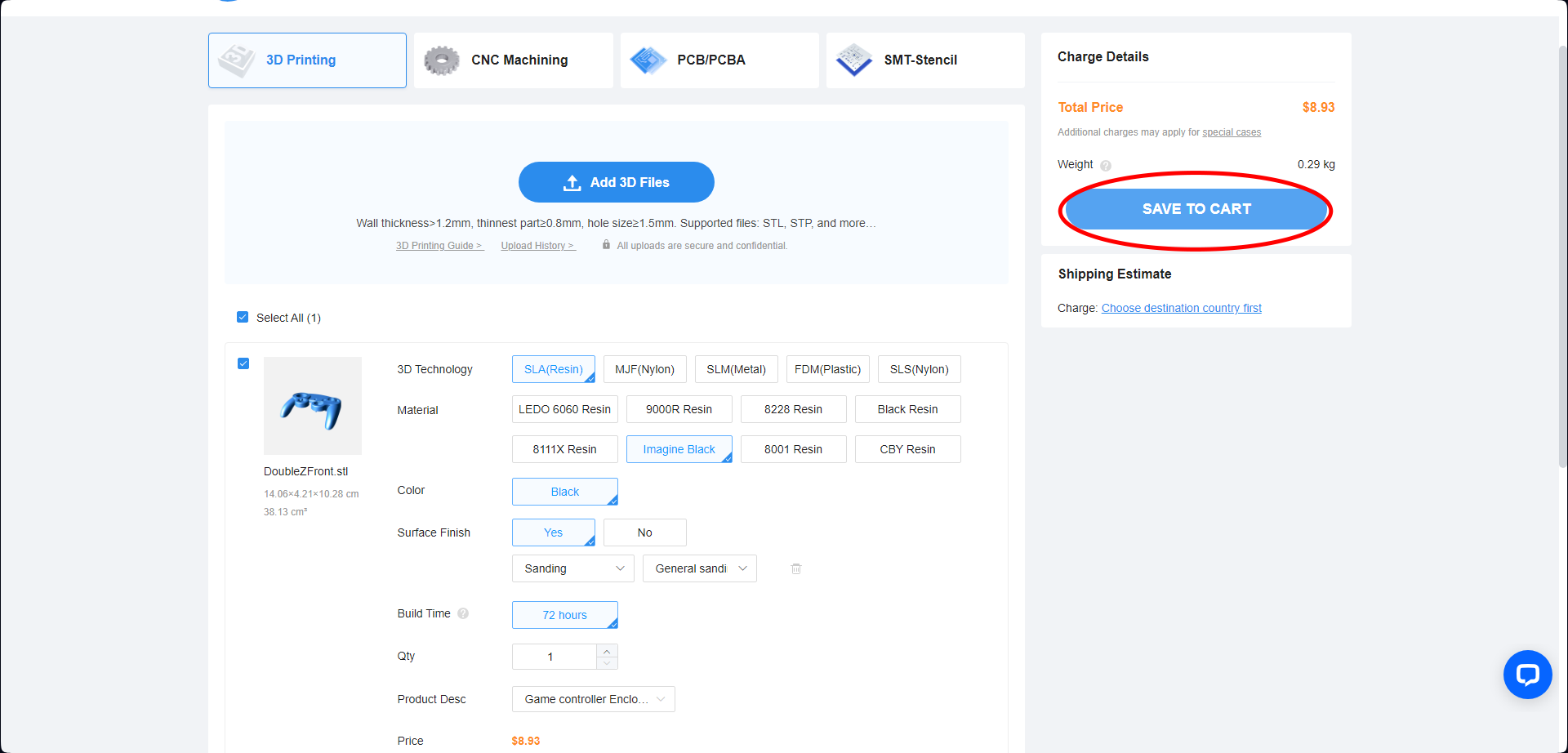

Once you are done with the settings on each individual STL uploaded, go ahead and "SAVE TO CART"

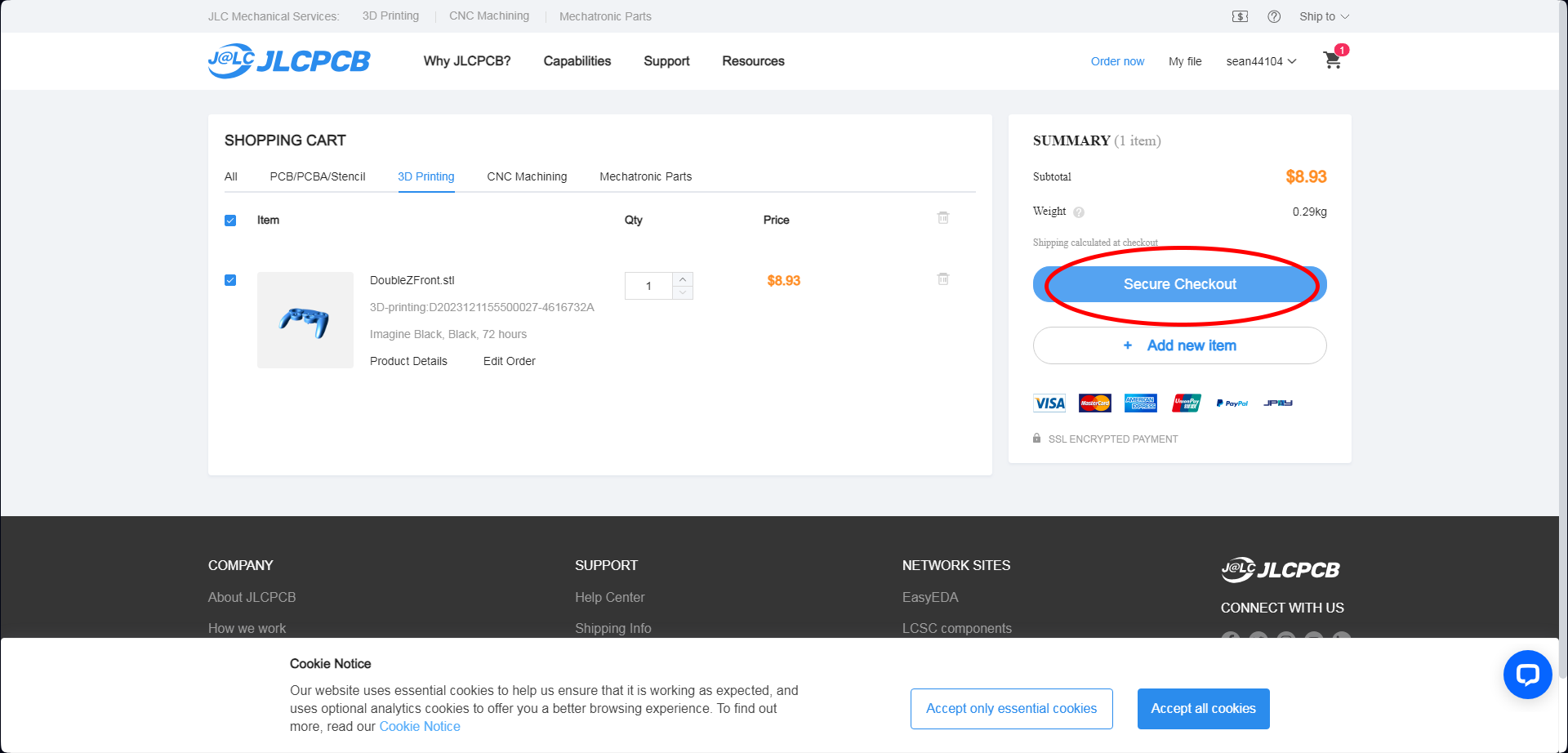

Lastly, "Secure Checkout" and put in your payment information! Shipping can be a lot, be prepared for that

I am currently writing this up, its a work in progess. Eventually I hope to have useful documented information on each material available so that you can make the best decisions possible when ordering parts. Give me time!

For now, here are my general recomendations. I have tried a TON of the JLC materials, so if you ever have a question about any of them, try DMing me!

For the gateplates, I think BY FAR the best material for them is 8001 Translucent, Oil Sprayed Resin. It is tough, dimensionally reliable, beautiful, and has very low friction! Rienne herself has rated the Notched 8001 Translucent gateplates as a 9/10!

For the shell, you have options. Either go with MJF Nylon, Black Resin, Imagine Black, or 8228 Resin. Nylon can be really nice, but it feels rough in the hands which can mean a lot of friction. Black Resin and Imagine Black are the exact same, except Imagine Black is a darker shade. They are both smooth and nice, but fragile. Apparently the 8228 Resin is the best of both worlds, being smooth like the black resins yet a bit more durable and less brittle. Only problem is that its a little ugly. My personal preference is Imagine Black, but I have not tried a full shell in 8228. 8001 Translucent Oil Spray is also an option for the shell. Its pretty and durable and it will work but the fit isnt the best, experiment at your own risk to your bank account!

For other miscellaneous small things, like buttons or triggers, go with Black Resin. Its cheap and will give you by far the best results. It is very smooth and high resolution, and its very accurate even at small sizes. I have generally loved the parts I have gotten in this material. I dont recommend it for gateplates though, because it is higher friction than alternatives and it can sometimes the gate can print wide and inaccurately when using black resin.

Click to expand

Resin does not melt. Do not try to melt it. It will begin to disintegrate instead of melt. With that being said, I do believe that you can soften resin with heat. If something is slightly warped, you can run it under hot water and gently bend it.

Resin is brittle. If you try and cut it with flush cutters, it is likely to break off in a larger piece than you anticipated. I recommend sanding it and being gentle with your physical modifications of the material. If you drop it, it may break. Screw posts especially end up being very fragile. This is why i designed the metal threads mod. that way, you dont thread into it. I left the back shell as it is though, so you will have to thread there for the trigger guards. I didn't do metal threads here because the posts are so small that I couldn't find a good part for it. Also, the trigger guards are less important than the shell screws. Lastly, I have never had the trigger guard screw posts actually break in any way.

White resins will yellow when exposed to UV (sunlight) over time. If you order a part in LEDO6060, expect it to be a bit yellowed in about 6 months.

While it is likely not a huge deal, you should probably try and minimize the amount of UV exposure your parts get. Keep them out of direct sunlight. Just like most materials, including plastic, resin never stops reacting to uv light, even when “fully cured” and solid. With enough UV light, it will even begin to degrade. Clear coating your parts would probably help with this.

I am not a professional on this subject. Information on this topic tends to be very unclear and vague. Please do your own research and carefully vet the people who you get your information from. I have done my best to do good research on this and come to my own personal conclusion. The following is my honest opinion

SLA UV Resin is initially a liquid. When exposed to UV light, it cures and hardens into a solid. When UV Resin is in its uncured liquid state, it is toxic. It is not safe to touch with bare hands or breathe in its fumes. This is all very important to think about when doing your own resin printing. I own a resin printer and I do my best to take the proper safety precautions when using it. I use gloves when working with it and I wear a mask. I clean the parts with isopropyl alcohol and fully cure them with a UV lamp. When you get a part from JLCPCB, it is complete. Fully cured, solid, perfect, ready to go. But does that mean that these parts are 100% safe? From my own research, I am of the opinion that the safety of UV resin is like an asymptote. As it cures, it becomes safer and safer, to the point of being mostly safe when fully cured. But does it ever reach a point of being absolutely 100% without a shadow of a doubt safe? I don't know, and I don't think anyone else really knows either. I can not responsibly make the claim that it is absolutely safe, because I don't know. The jury is very much out on this. The long term risks of exposure to uv resin are not fully understood due to a lack of research. The long term risks of exposure to fully cured uv resin in the hands is even less understood

The safety of UV resins also likely depends on the resin. For example, UV resin is used in the medical field. SLA parts are used for tissue contact medical device applications. Is the resin that JLC uses as safe as the resin used in the medical field? I can not say for sure. I have put in an inquiry to JLCPCB for a Material Safety Data Sheet on their different resins. They were only able to provide me with one for their LEDO6060 resin. Furthermore, the information provided in the MSDS is clearly targetted at the uncured version of the resin. This is because safety precautions are most important when working with the material in the production phase. The MSDS is more made for them while they make the parts, not really for the end user. This makes finding information about the safety of these parts even more difficult.

If you would like to read the MSDS for yourself, here it is. Let me know if you find anything useful! https://cdn.discordapp.com/attachments/684468475464384723/1189654549963743292/MSDS_Ledo6060.pdf?ex=659ef323&is=658c7e23&hm=a3720d4aae3bad57797445d258488913121f4ed673805fa01456909fc8037068&

Here is a link to a research paper done about this subject: https://pubs.acs.org/doi/10.1021/acs.estlett.5b00249 Here is a link to their results: https://pubs.acs.org/doi/suppl/10.1021/acs.estlett.5b00249/suppl_file/ez5b00249_si_001.pdf

In this publication, the researchers tested multiple different stages of UV resin cured-ness on zebrafish embryos. After printing a part, it comes off the printer wet and very soft (not fully cured whatsoever). You must clean it and cure it. The researchers did a total of 5 resin print tests. 4 of the 5 used parts that were only cleaned, and not fully cured. Only their 5th test was cured. Interestingly, you can see from the graphs that while the 4 uncured parts were extremely harmful to the zebrafish embryos, the 5th test was either significantly less harmful or indistinguishable from the control test. This clearly shows that curing UV Resin makes it drastically more safe. Furthermore, this is a very sensitive testing environment, and you are not a zebrafish embryo

With all of that being said, I personally use these parts. I have for over a year and I will continue to use them. I am not personally particularly worried about my resin controller. If you feel differently about this however, here are some steps you can take.

Choose a different material

JLC has many different types of 3D Technology beyond just SLA Resin! Instead of SLA Resin, you can go for either SLS Nylon or MJF Nylon. These materials are 100% safe to use and touch.

Paint or Clear Coat your resin

By putting a layer between you and the resin, you can make it for sure safe to touch. If you are especially worried about the safety risks of SLA Resins, but still want to use them, or if you are planning on selling resin printed parts at large scales, I would recommend that you hit them with a little clear coat

When researching the safety of UV resin for yourself, please be aware that most of the information online is aimed at people who resin print themselves. This environment has safety hazards, and this is the context that discussions about safety are usually in. Please do not be irresponsible and spread misinformation about the harmful effects of cured resin parts based on the information you read that was likely referring to liquid or uncured resin parts.