Section 2.1 Assembly of the Y Unit Mounting the threaded Rods and Power Supply

|

|

|

|

|

|

|

|

|

-

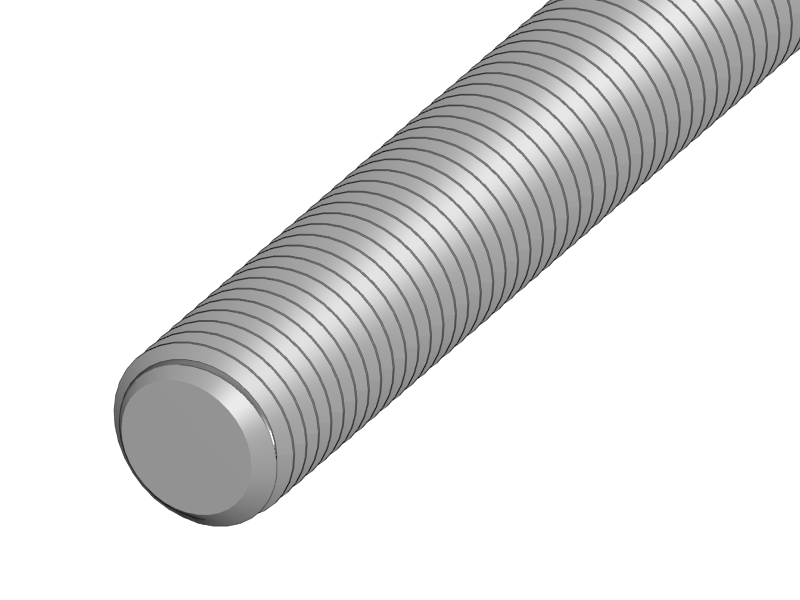

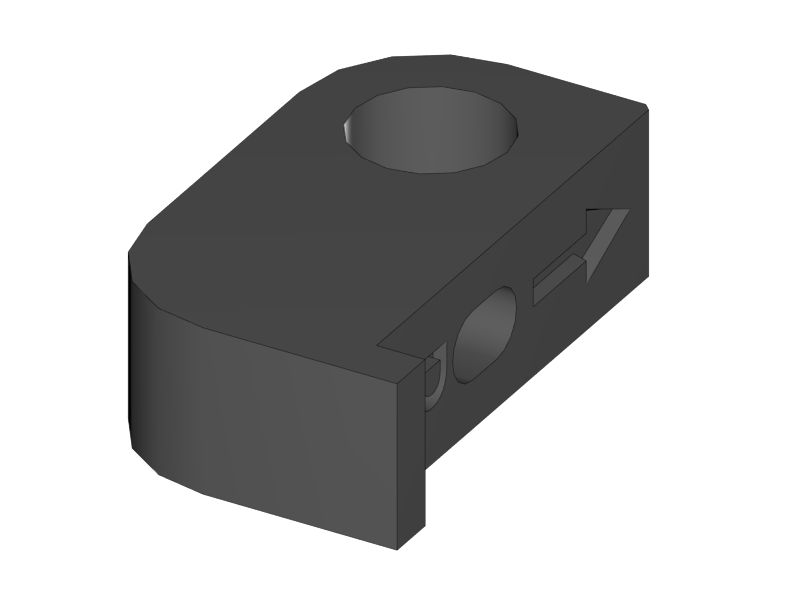

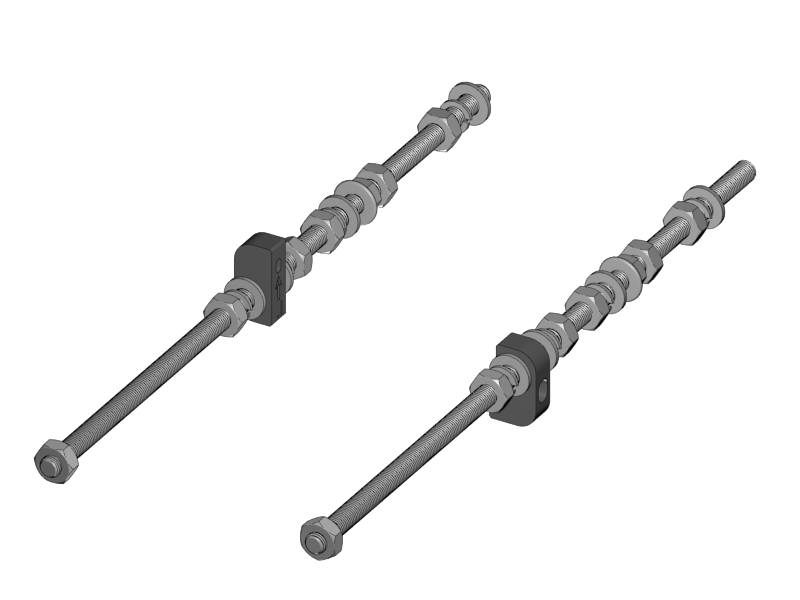

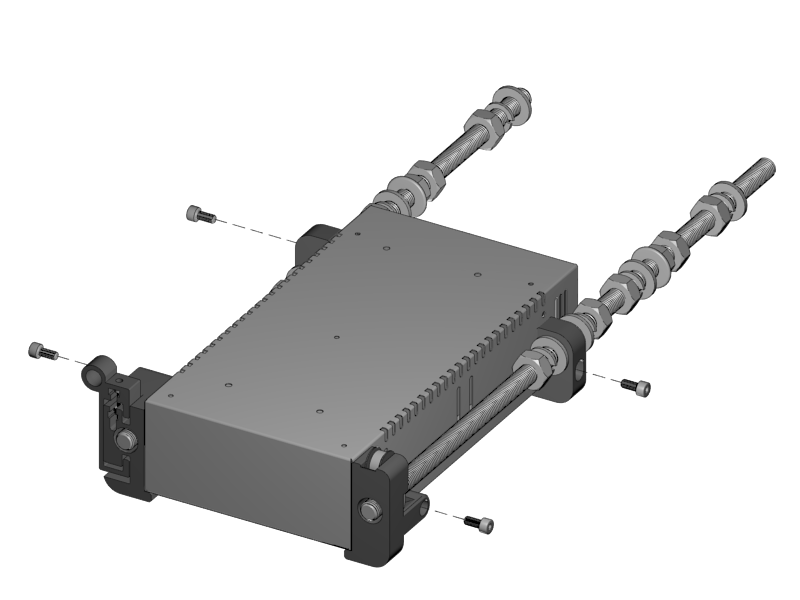

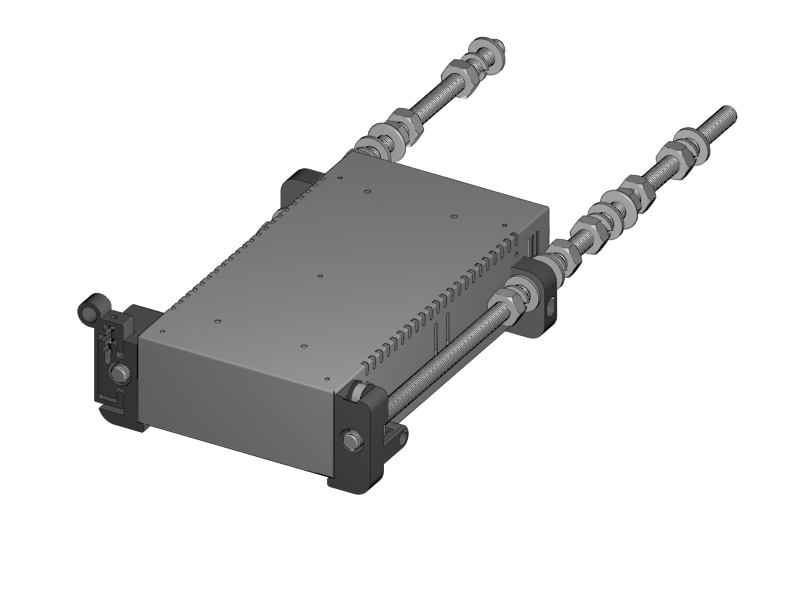

Slide the right Power-Supply mount onto the M10 rod.

-

Put a washer on both sides.

-

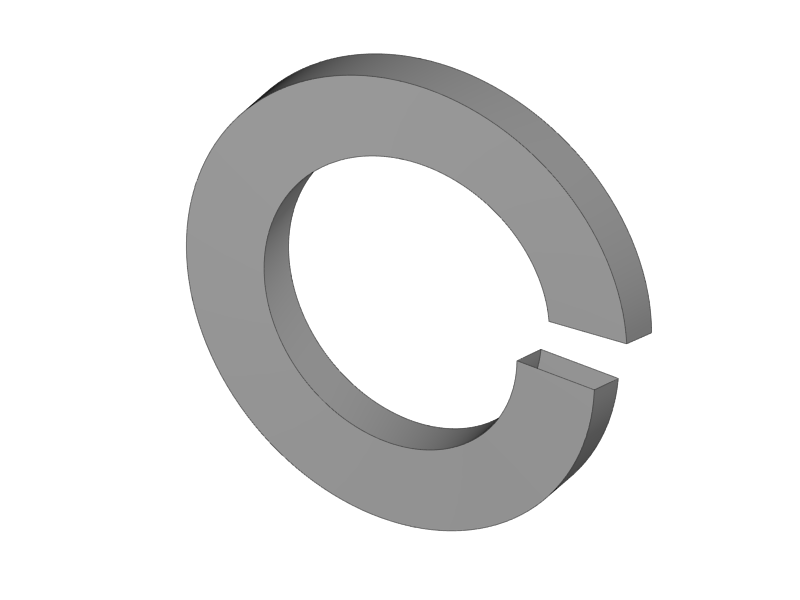

Two spring washers on both sides

-

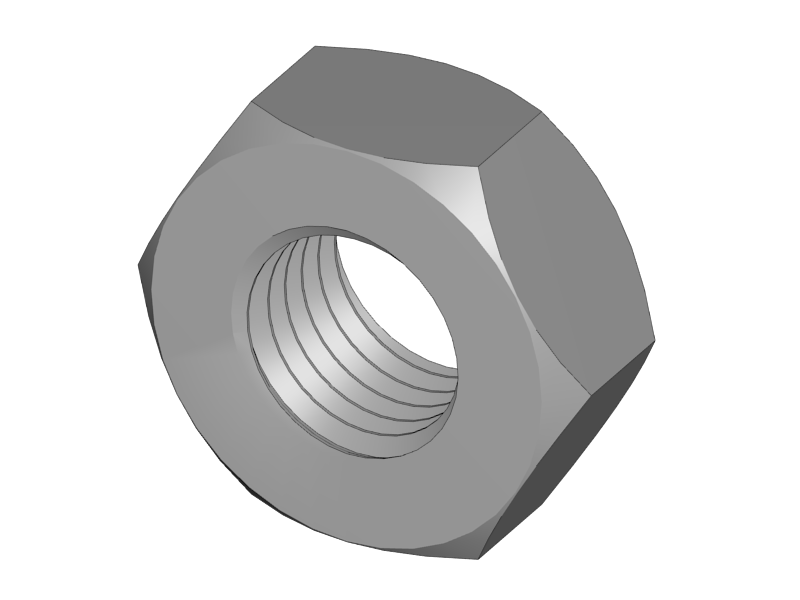

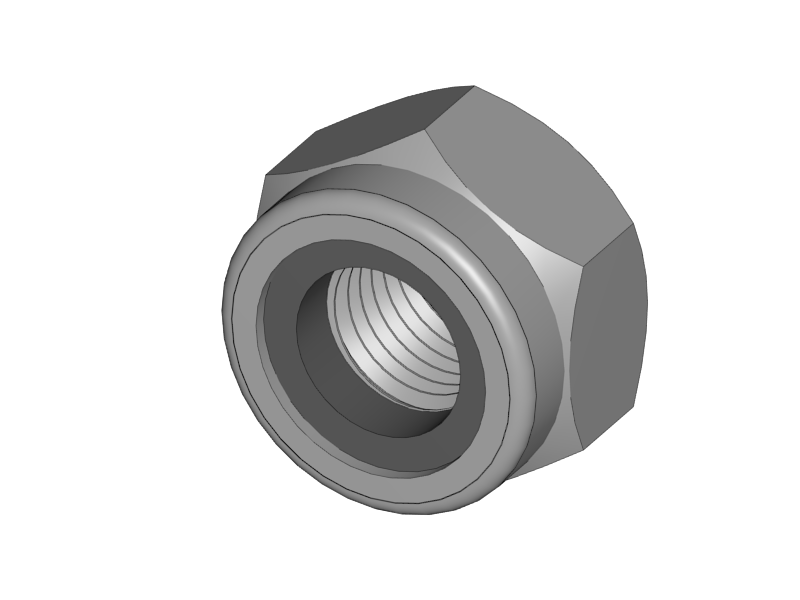

and two nuts on both sides.

-

Do not make the nuts tight yet. Leave about 5cm place between the nuts.

|

|

|

|

|

|

|

-

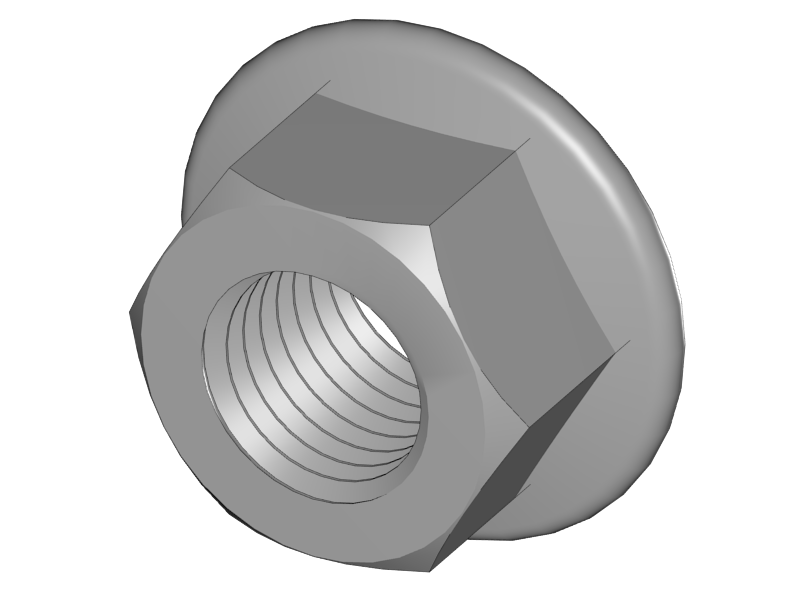

Mount a nut, spring washer, washer and flange nut to the threaded rod for later mounting the XZ plate.

-

Also put an M10 nut on both ends for later mounting the front and back-plate.

-

Do not make anything tight yet.

|

-

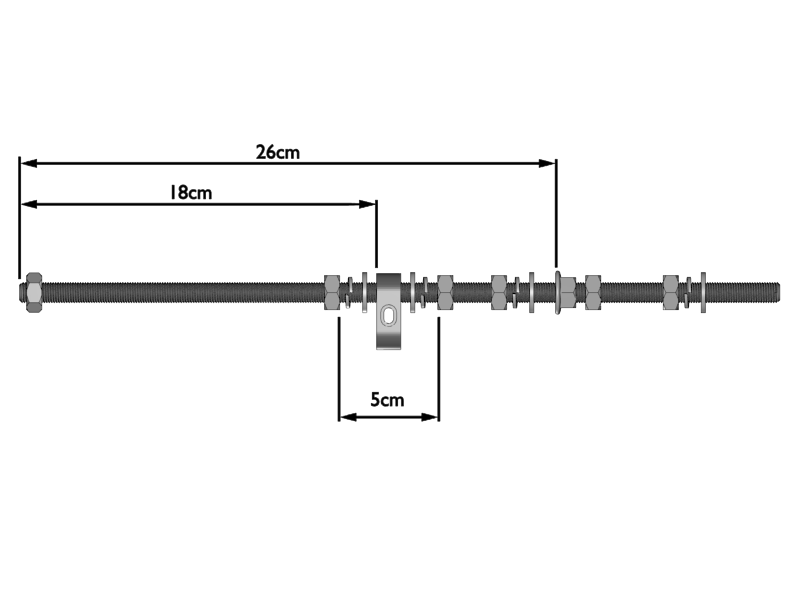

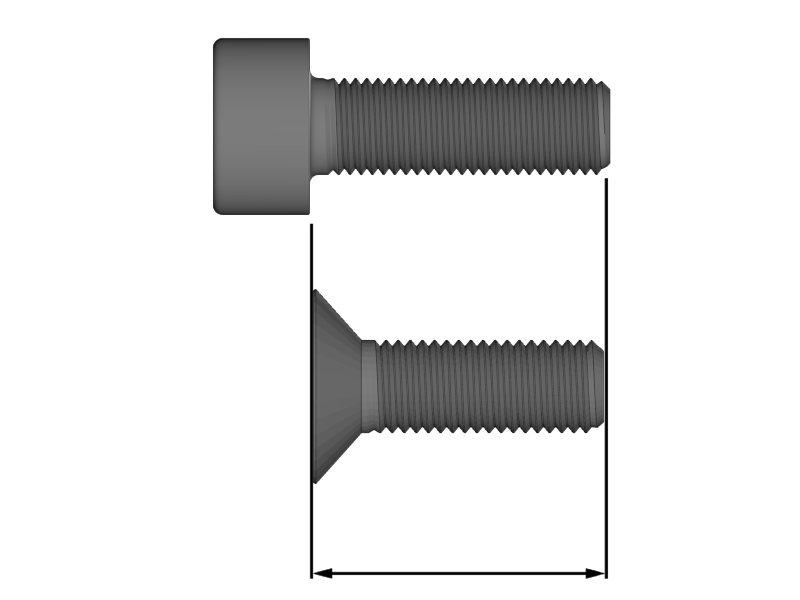

The power-supply mount is about 18 centimeters from the front side of the rod.

-

The flange is about 26 centimeters from the front.

-

Don’t make this precise, measurements are just for reference for easier assembly later on.

|

|

|

|

|

|

|

|

|

|

|

-

Do the same for the left-hand rod.

-

Make sure that the orientation of the plastic parts is correct. The arrows should be pointing upwards.

|

|

|

|

|

|

|

|

|

-

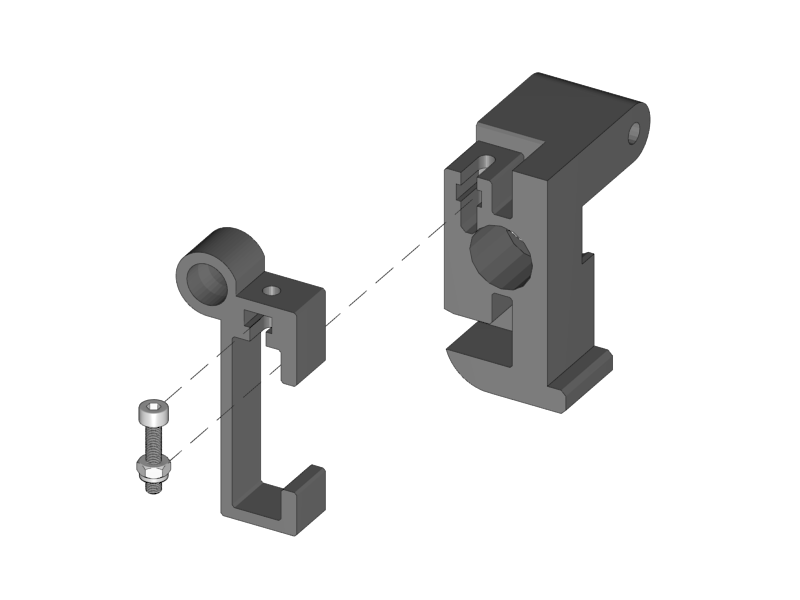

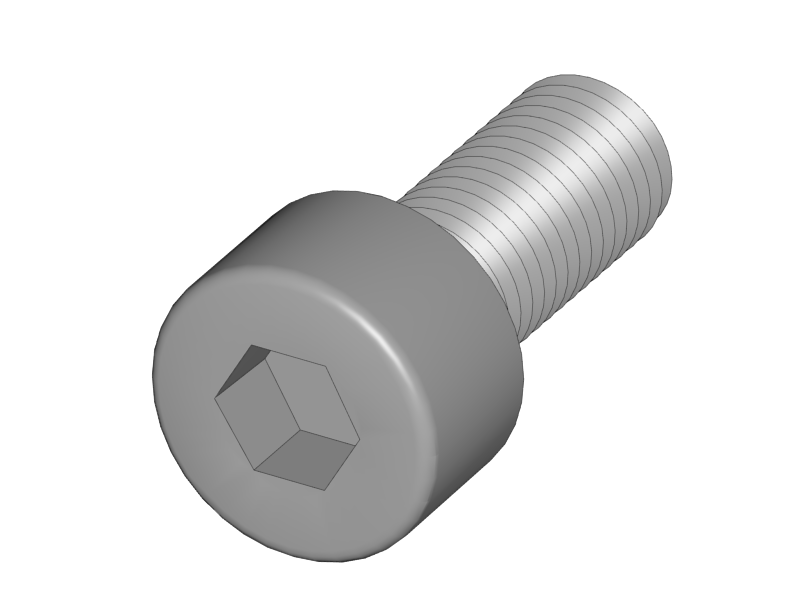

Turn the nut about 5mm onto the screw

-

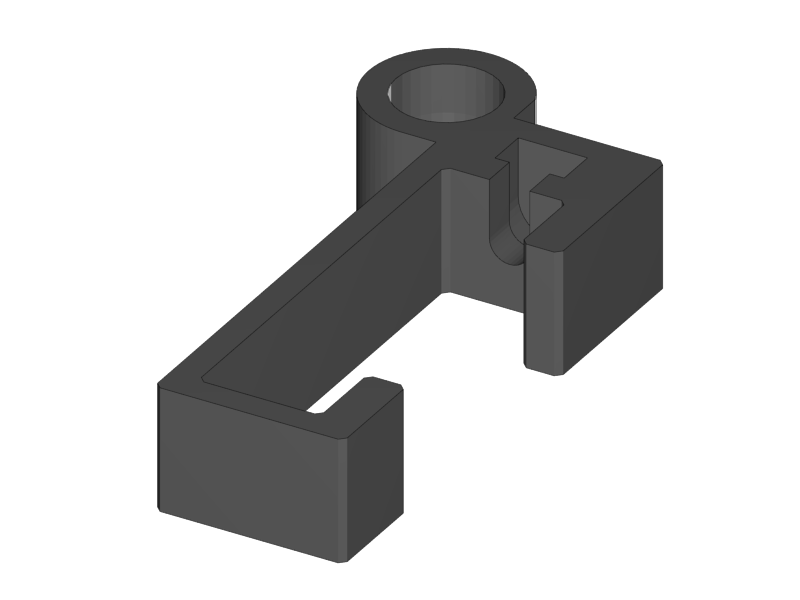

Put the Y-Height Adjuster into the Y-FrontLeft part

-

Push the screw and nut into the slots of the plastic parts

-

Make sure the hexagon of the screw is reachable through the hole in the Height adjuster

-

Later this assembly will enable you to adjust the height of the smooth rod

-

|

|

|

|

|

|

|

-

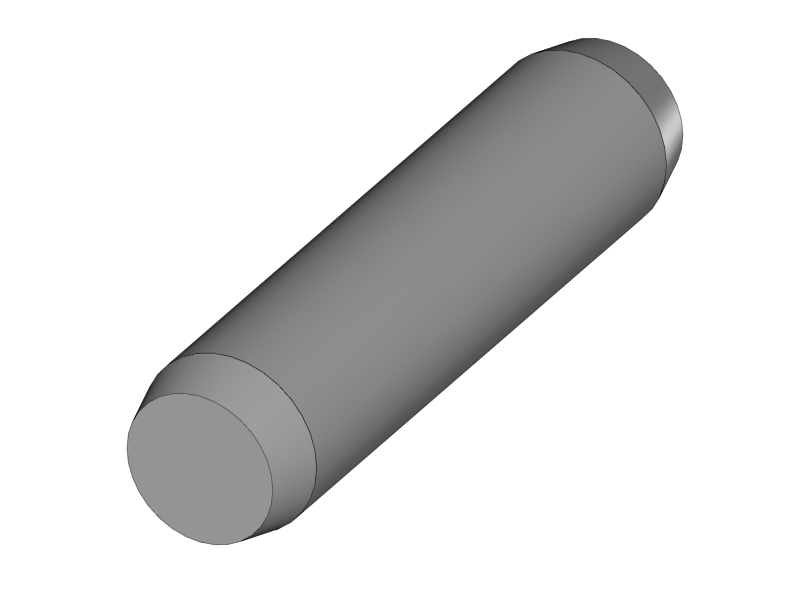

Put the bearing with the two belt guiding discs into the slot of the front right Y-Corner.

-

Make sure the little notch of the discs is on the inside and the shiny side is point outwards.

-

Slide in the dowel to fix the assembly.

|

-

Put the black sticker on the power supply to make it look nice.

|

|

-

Mount the front Y mounts to the M10 rods.

-

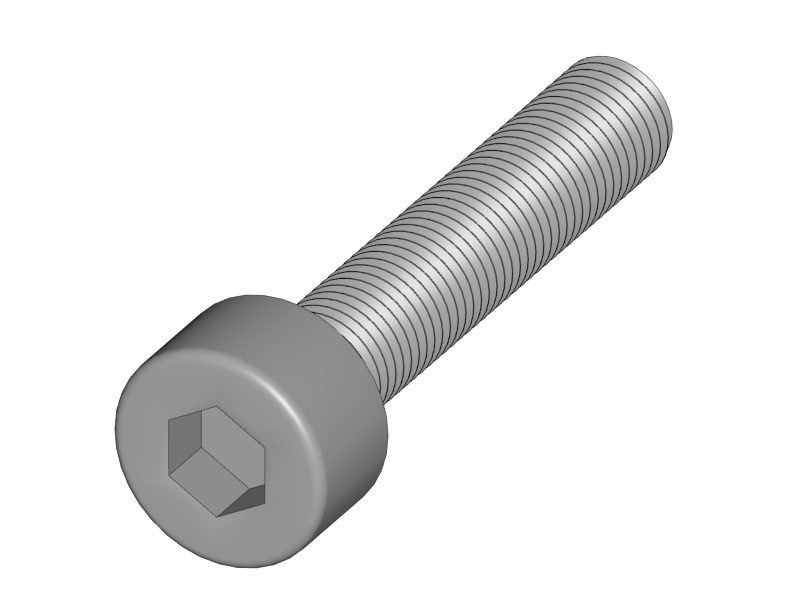

Mount the power-supply on the plastic parts with 4 M4 x 10 screws.

-

Note the air outlet of the power-supply will be facing downwards.

|

Great you now completed the first step of the assembly. Go on with the next step.

##i3 Berlin

1 Introduction

1.1: History

1.2: Tools and Parts

1.3: Preparing the Casings

2 Assembly of the Y-Unit

2.1: Rods and Power Supply

2.2: Front- and Back- Plate

2.3: Mounting Y-Carriage and Belt

3 Assembly of the XZ-Unit

3.1: Mounting the X-Axis

3.2: Mounting the Z-Axis

3.3: Mounting the Timing Belt

3.4: Assembling the Extruder

4 Wiring

4.1: Wiring the Power Supply

4.2: Wiring the Z-Unit

4.3: Wiring the Y-Unit

4.4: Wiring the X-Axis

4.5: Gluing the Endstop Magnets

4.6: Uploading Firmware

4.7: Wiring the Extruder

4.8: Mounting the Heatbed

5 Calibration

5.1: Testing Functionality

5.2: Calibrating the Y Axis

5.3: Calibrating the X Axis

5.4: Calibrating the Print Platform

6 Printing

6.1: Filament Holder

6.2: Cura

6.3: Kisslicer

6.4: Dual Printing