-

Notifications

You must be signed in to change notification settings - Fork 116

New issue

Have a question about this project? Sign up for a free GitHub account to open an issue and contact its maintainers and the community.

By clicking “Sign up for GitHub”, you agree to our terms of service and privacy statement. We’ll occasionally send you account related emails.

Already on GitHub? Sign in to your account

some questions for creating irb6700 155/2.85 support package #123

Comments

According to the commit history, the variant you refer to was contributed by @marip8 in #116. @marip8: would you happen to remember where you got the joint limits for the 200/2.6m variant? They do seem to be different from the ones in the quoted documentation.

There are no known limits for that part of the robot geometry. The limits present are there to allow for the typical motion of these parts, without restricting them. Those limits do not come from any documentation of data sheet. If the variant you're adding has a similar structure, you could most likely reuse the ones you found.

For the visual aspect of the model, a visual inspection is used (ie: does the model look complete, do the meshes look correct, are there no obvious defects, are the mesh normals correct (ie: no inverted normals), etc). It's also important to check whether the meshes are not overly detailed. Anything above a few hundred KB for Also make sure to have correct For the kinematic structure, a good approach would be to compare the result of looking up the Both position and orientation should match to a significant number of decimals. Next, compare the directions of rotation to what the manual specifies. You could either do this manually, for each joint, using the Especially important is the J2-J3 coupling factor. But if that's incorrect you'll immediately notice it when moving the robot around in RobotStudio, as it will lead to unexpected motions of the lower arm (ie: links 3 and later). |

please note: variants of robot series for which support packages already exist should be placed in the package for that series. So in your case, the 155/2.85 could be placed as a variant in the existing There would be no need to create a new separate package. |

|

We'll track the potentially incorrect joint limits in #124. |

|

As we're tracking the potential issue with the joint limits in #124, and the rest of this post is asking for guidance instead of reporting other problems, I'm going to close the issue. Feel free to keep commenting on it of course. |

|

Thank you very much for your help! |

|

No problem. It would of course be very much appreciated if you could contribute support for the variant by submitting a pull request. |

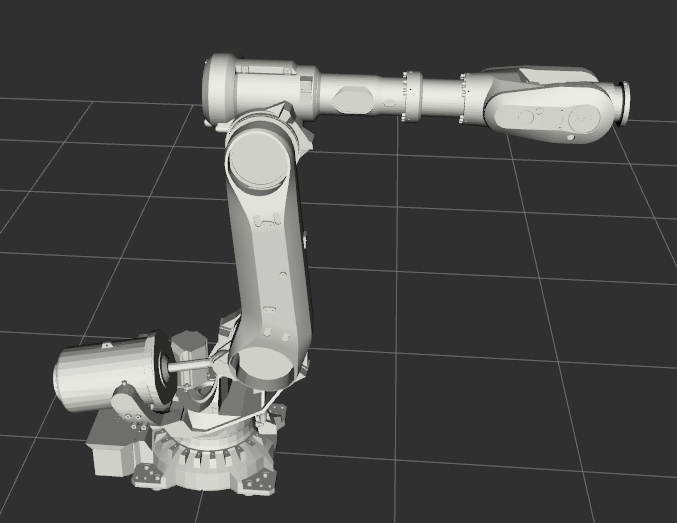

Hi, recently I am trying to create a irb6700 155/2.85 support package based on abb_irb6700_support. I have some questions, could you give me some help?

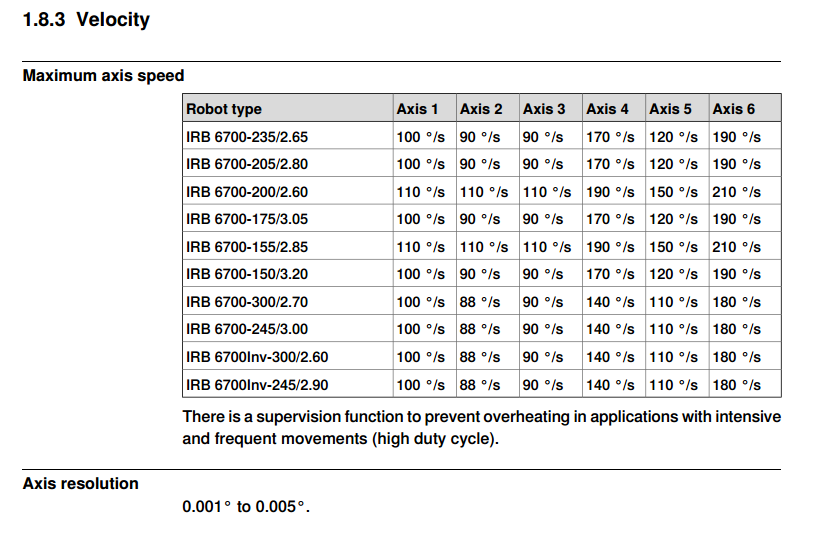

According to abb's 6700 product specification,

6700 200/2.60's max axis speed is [110, 110, 110, 190, 150, 210]degree/s. However, in irb6700_200_260_macro.xacro, velocity limits are [100, 90, 90, 170, 120, 190]. It is confusing for me.

I noticed that in irb6700_200_260_macro.xacro, there are cylinder_joint and pistion_joint definition. And according to this, limit value seems not important. I haven't found any infomation about piston and cylinder in any document until now. So could you tell me how you get these limit information please? Is it right that I keep your values unchanged for 6700 155/2.84?

Although in RViz, everything looks OK, I still want to know how you verify robot's urdf. Could you give some instructions?

Thank you very much!

The text was updated successfully, but these errors were encountered: